A kind of α-olefin polymerization catalyst and its preparation method, α-olefin polymerization method

A technology for olefin polymerization and catalyst, which is applied in the field of α-olefin polymerization catalyst and its preparation, and the field of α-olefin polymerization, and can solve problems such as difficulty in controlling the degree of reduction of active centers, reduction in product viscosity and performance, and reduction in polymerization activity. , to achieve the effect of easy separation of catalyst and product, increase of viscosity index and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

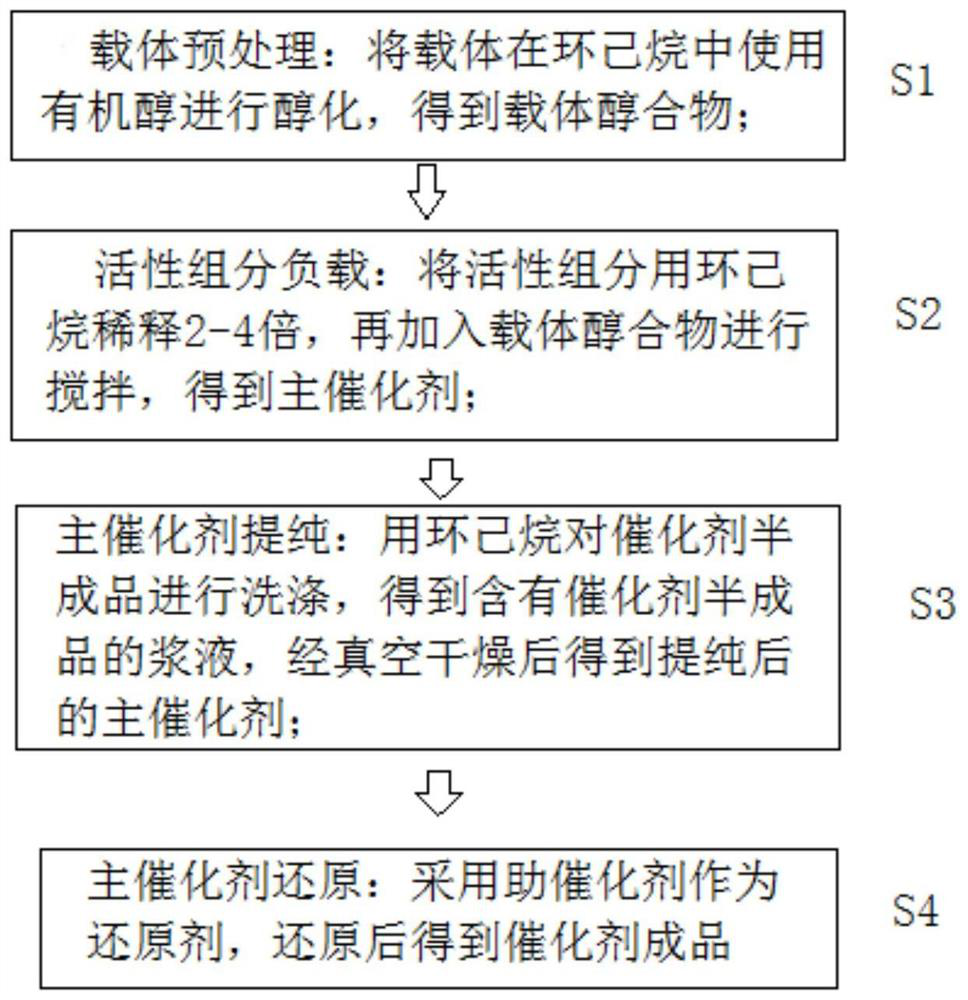

Method used

Image

Examples

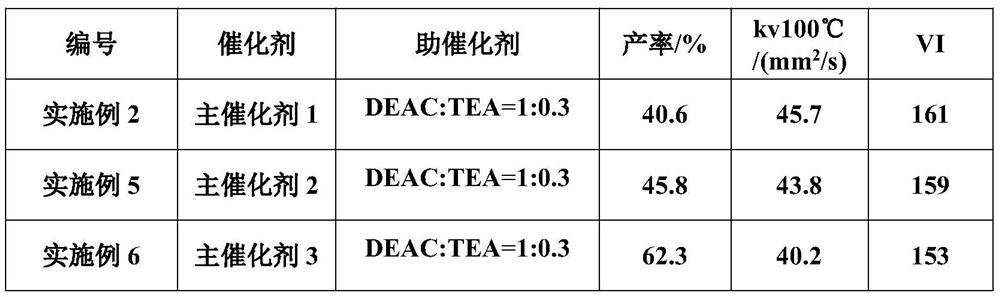

preparation example 1

[0062] Preparation of main catalyst 1

[0063] A three-necked reaction flask equipped with a stirrer and a thermometer was replaced with high-purity nitrogen three times, and 15.5gMgCl was added to the reaction vessel 2 With 50ml of cyclohexane; at 60°C, add 10ml of n-butanol dropwise at a rate of 3-4 seconds / drop to form an alcoholate with the carrier;

[0064] After the reaction, lower the temperature to 25°C, take 2.55ml of titanium tetrachloride, add cyclohexane twice the volume ratio to make a titanium tetrachloride solution, and add it to the carrier at a rate of 3-4 seconds / drop while stirring In the alcoholate, continue to stir for 1h after the dropwise addition;

[0065] After the reaction of the supported titanium active center is completed, the reaction liquid is filtered out under the protection of an inert gas, and the above-mentioned generated material is subjected to multiple thermal washings with cyclohexane, and the washing supernatant is transferred to obtai...

preparation example 2

[0067] Preparation of main catalyst 2

[0068] A three-necked reaction flask equipped with a stirrer and a thermometer was replaced with high-purity nitrogen three times, and 15.5gMgCl was added to the reaction vessel 2 With 50ml of cyclohexane; at 60°C, add 10ml of n-butanol dropwise at a rate of 3-4 seconds / drop to form an alcoholate with the carrier;

[0069] After the reaction, lower the temperature to 25°C, take 3.83ml of titanium tetrachloride, add cyclohexane with twice the volume ratio to make a titanium tetrachloride solution, and add it to the carrier at a rate of 3-4 seconds / drop while stirring In the alcoholate, continue to stir for 1h after the dropwise addition;

[0070] After the reaction of the supported titanium active center is completed, the reaction liquid is filtered out under the protection of an inert gas, and the above-mentioned generated material is subjected to multiple thermal washings with cyclohexane, and the washing supernatant is transferred to ...

preparation example 3

[0072] Preparation of main catalyst 3

[0073] A three-necked reaction flask equipped with a stirrer and a thermometer was replaced with high-purity nitrogen three times, and 15.5gMgCl was added to the reaction vessel 2 With 50ml of cyclohexane; at 60°C, add 10ml of n-butanol dropwise at a rate of 3-4 seconds / drop to form an alcoholate with the carrier;

[0074] After the reaction, lower the temperature to 25°C, take 5.1ml of titanium tetrachloride, add cyclohexane with twice the volume ratio to make a titanium tetrachloride solution, and add it to the carrier at a rate of 3-4 seconds / drop while stirring In the alcoholate, continue to stir for 1h after the dropwise addition;

[0075] After the reaction of the supported titanium active center is completed, the reaction liquid is filtered out under the protection of an inert gas, and the above-mentioned generated material is washed with cyclohexane for several times, and the supernatant liquid is transferred to obtain a high-ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com