Hydroxy group and epoxide group co-terminated linear polysiloxane preparation technology

A polysiloxane, preparation technology, applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of breaking emulsion sticky roll, non-hydrophilic, epoxy-based silicone oil semi-hydrophilic, etc., to speed up water absorption, improve Soft and slippery properties of fabrics, the effect of improving hydrophilicity and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

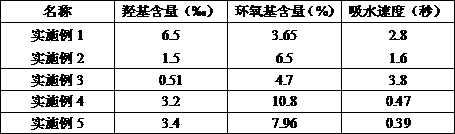

Examples

Embodiment 1

[0021] Add DMC into the reaction kettle and raise the temperature to 80-85°C, add tetramethylammonium hydroxide solid catalyst under the protection of nitrogen, catalyze the polymerization for 10 minutes, the viscosity of the material in the kettle is 300000cs; raise the temperature to 110°C, add a certain amount under the protection of nitrogen The amount of water added is 0.03% of the DMC mass for the first degradation, the equilibrium reaction is 1h, and the viscosity drops to 80000cs; then add 1,3-bis(3-glycidylpropyl)-1,1,3,3- Tetramethyldisiloxane was degraded for the second time, the addition amount was 1.8% of the DMC mass, the equilibrium reaction was 4h, the viscosity dropped to 1800cs; the temperature was raised to 140°C to decompose the catalyst, and the gas discharged from the exhaust port of the reactor was detected to be neutral Finally, turn on the vacuum pump, the vacuum degree is -0.095-0.01MPa to remove low-boiling volatile substances, and obtain a linear pol...

Embodiment 2

[0023] Add DMC into the reaction kettle and raise the temperature to 80-85°C, add tetramethylammonium hydroxide solid catalyst under the protection of nitrogen, catalyze the polymerization for 30 minutes, the viscosity of the material in the kettle is 380000cs; raise the temperature to 110°C, add a certain amount under the protection of nitrogen The amount of water added is 0.15% of the DMC mass for the first degradation, the equilibrium reaction is 1h, and the viscosity drops to 40000cs; then add 1,3-bis(3-glycidylpropyl)-1,1,3,3- Tetramethyldisiloxane was degraded for the second time, the addition amount was 2.5% of the mass of DMC, the equilibrium reaction was 4h, and the viscosity dropped to 970cs; the temperature was raised to 140°C to decompose the catalyst, and the gas discharged from the exhaust port of the reactor was detected to be neutral Finally, turn on the vacuum pump, and the vacuum degree is -0.095-0.01MPa to remove low-boiling volatile substances, and obtain a ...

Embodiment 3

[0025] Add DMC into the reaction kettle and raise the temperature to 80-85°C, add tetramethylammonium hydroxide alkali gel catalyst under the protection of nitrogen, catalyze the polymerization for 10 minutes, and the viscosity of the material in the kettle is 350000cs; raise the temperature to 110°C, add some The amount of water added is 0.03% of the DMC mass for the first degradation, the equilibrium reaction is 1h, and the viscosity drops to 91000cs; then add 1,3-bis(3-glycidylpropyl)-1,1,3,3 -Tetramethyldisiloxane is degraded for the second time, the addition amount is 1.8% of the DMC mass, the equilibrium reaction is 4h, and the viscosity drops to 1560cs; the temperature is raised to 140°C to decompose the catalyst, and the gas discharged from the exhaust port of the reactor is detected to be medium After curing, turn on the vacuum pump with a vacuum degree of -0.095-0.01MPa to remove low-boiling volatile substances, and obtain a linear polysiloxane product co-terminated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com