Preparation method of yellowing-resistant and high-brightness ABS resin

An ABS resin and high whiteness technology, applied in the preparation of high whiteness ABS resin and the field of yellowing resistance, can solve the problems of migration and precipitation, limited dispersion effect, etc., and achieve the effect of reducing yellow index, promoting dispersion and preventing migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

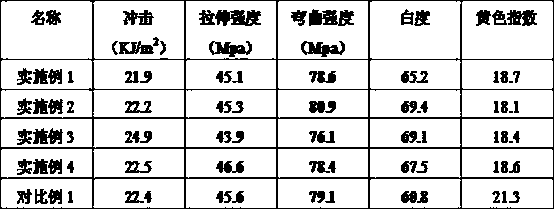

Examples

Embodiment 1

[0017] In terms of parts by mass, put 300g of polybutadiene latex (average particle size 320nm, solid content 40%) on a dry basis in a 2000ML reactor, add 3g of rosin soap on a dry basis, 1g of anhydrous Potassium carbonate, 0.6g initiator cumene hydroperoxide, 0.1g reducing agent ferrous sulfate, 0.3g chelating agent sodium pyrophosphate, 0.5g co-reducing agent fructose and 1200g desalinated water were stirred at room temperature for 10 minutes to make them After all the additives were completely dissolved, nitrogen was introduced into the reaction kettle to replace the air inside the reaction kettle twice. The temperature was raised to 65°C.

[0018] After the temperature of the reactor is stabilized for 10 minutes, slowly add 150 g of styrene, 50 g of acrylonitrile, 5 g of vinyl phosphate functional monomer, and 0.5 g of initiator cumene hydroperoxide dropwise to the reactor, and the dropping time is 2.5 Hours, after the dropwise addition, 0.1g of the initiator was added d...

Embodiment 2

[0022] In terms of parts by mass, put 300g of polybutadiene latex (average particle size 320nm, solid content 40%) on a dry basis in a 2000ML reactor, add 3g of rosin soap on a dry basis, 1g of anhydrous Potassium carbonate, 0.6g initiator cumene hydroperoxide, 0.1g reducing agent ferrous sulfate, 0.3g chelating agent sodium pyrophosphate, 0.5g co-reducing agent fructose and 1200g desalinated water were stirred at room temperature for 10 minutes to make them After all the additives were completely dissolved, nitrogen was introduced into the reaction kettle to replace the air inside the reaction kettle twice. The temperature was raised to 65°C.

[0023] After the temperature of the reactor is stabilized for 10 minutes, slowly add 150 g of styrene, 50 g of acrylonitrile, 10 g of vinyl phosphate functional monomer, and 0.5 g of initiator cumene hydroperoxide dropwise to the reactor, and the dropping time is 2.5 Hours, after the dropwise addition, 0.1g of the initiator was added ...

Embodiment 3

[0027] In terms of parts by mass, put 300g of polybutadiene latex (average particle size 320nm, solid content 40%) on a dry basis in a 2000ML reactor, add 3g of rosin soap on a dry basis, 1g of anhydrous Potassium carbonate, 0.6g initiator cumene hydroperoxide, 0.1g reducing agent ferrous sulfate, 0.3g chelating agent sodium pyrophosphate, 0.5g co-reducing agent fructose and 1200g desalinated water were stirred at room temperature for 10 minutes to make them After all the additives were completely dissolved, nitrogen was introduced into the reaction kettle to replace the air inside the reaction kettle twice. The temperature was raised to 65°C.

[0028] After the temperature of the reactor is stabilized for 10 minutes, slowly add 150 g of styrene, 50 g of acrylonitrile, 10 g of vinyl diethyl phosphate monomer, and 0.5 g of the initiator cumene hydroperoxide dropwise to the reactor for a time of After 2.5 hours, add 0.1g of initiator dropwise to the reactor again after the drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com