High-density polyethylene compound additive and preparation method thereof

A technology of high-density polyethylene and compound additives, applied in the chemical industry, can solve the problems of dust pollution, inaccurate addition amount, endangering health, etc., and achieve the effect of increasing fracture strain, reducing yellow index, and reducing the amount of addition and usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 5kg of antioxidant 330, 44kg of antioxidant 168, 18kg of antioxidant 1076, 5kg of nucleating agent Hyperform HPN-20E, 15kg of acid absorbing agent DHT-4A and 15kg of antistatic agent were used as bis(β-hydroxyethyl) coconut According to the specific gravity, oleylamine is put into the high-speed mixer from light to heavy, and stirred at a speed of 800 rpm for 50 seconds at a temperature of 18-22°C, and then discharged into the conical feeder. It is conveyed to the granulator through the screw, and at each stage of the granulator, the temperature control device is used to control the temperature of each section to prevent the single agent from decomposing and sticking due to the difference in melting point (optimum processing temperature : The temperature of the heating section in the granulator is 55°C, the temperature of the head section is 60°C, and the air cooling temperature is 25°C). The extruded cylindrical strips pass through the conveyor belt air-cooling device ...

Embodiment 2

[0023] 15kg of antioxidant 330, 54kg of antioxidant 168, 28kg of antioxidant 1076, 1kg of nucleating agent Hyperform HPN-20E, 8kg of acid absorbing agent DHT-4A and 1kg of antistatic agent were bis(β-hydroxyethyl) coconut According to the specific gravity, oleylamine is put into the high-speed mixer from light to heavy, and stirred at a speed of 800 rpm for 50 seconds at a temperature of 15-18°C, and then discharged into the conical feeder. It is conveyed to the granulator through the screw, and at each stage of the granulator, the temperature control device is used to control the temperature of each section to prevent the single agent from decomposing and sticking due to the difference in melting point (optimum processing temperature : The temperature of the heating section in the granulator is 55°C, the temperature of the head section is 60°C, and the air cooling temperature is 25°C). The extruded cylindrical strips pass through the conveyor belt air-cooling device to keep t...

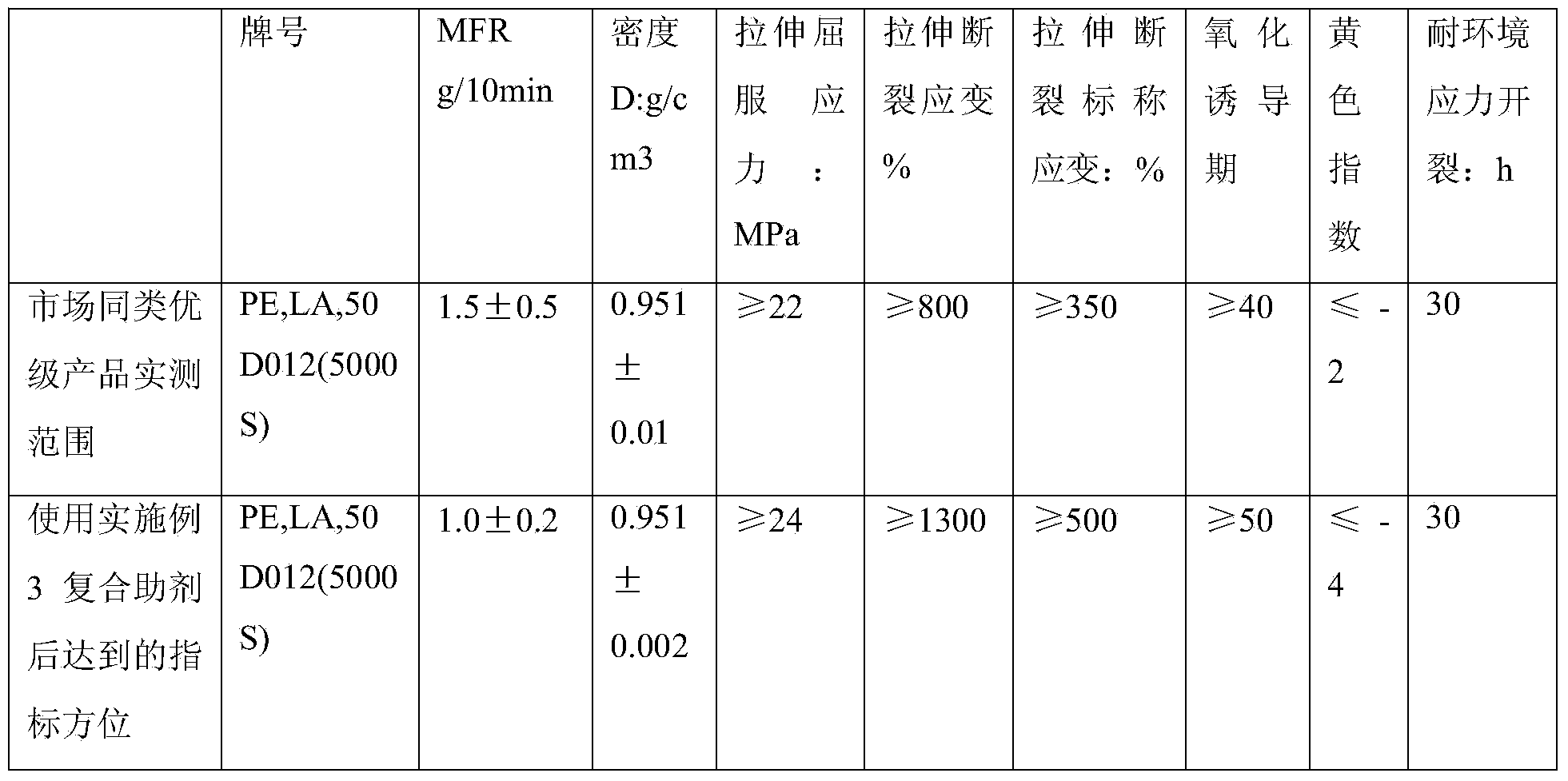

Embodiment 3

[0025] 7kg of antioxidant 330, 50kg of antioxidant 168, 20kg of antioxidant 1076, 3kg of nucleating agent Hyperform HPN-20E, 12kg of acid absorbing agent DHT-4A and 8kg of antistatic agent were used as bis(β-hydroxyethyl) coconut According to the specific gravity, oleylamine is put into the high-speed mixer from light to heavy, and stirred at a speed of 800 rpm for 50 seconds at a temperature of 0-5°C, and then discharged into the conical feeder. It is conveyed to the granulator through the screw, and at each stage of the granulator, the temperature control device is used to control the temperature of each section to prevent the single agent from decomposing and sticking due to the difference in melting point (optimum processing temperature : The temperature of the heating section in the granulator is 55°C, the temperature of the head section is 60°C, and the air cooling temperature is 25°C). The extruded cylindrical strips pass through the conveyor belt air-cooling device to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com