Additive composition for improving performance of lubricant, and preparation method and application method thereof

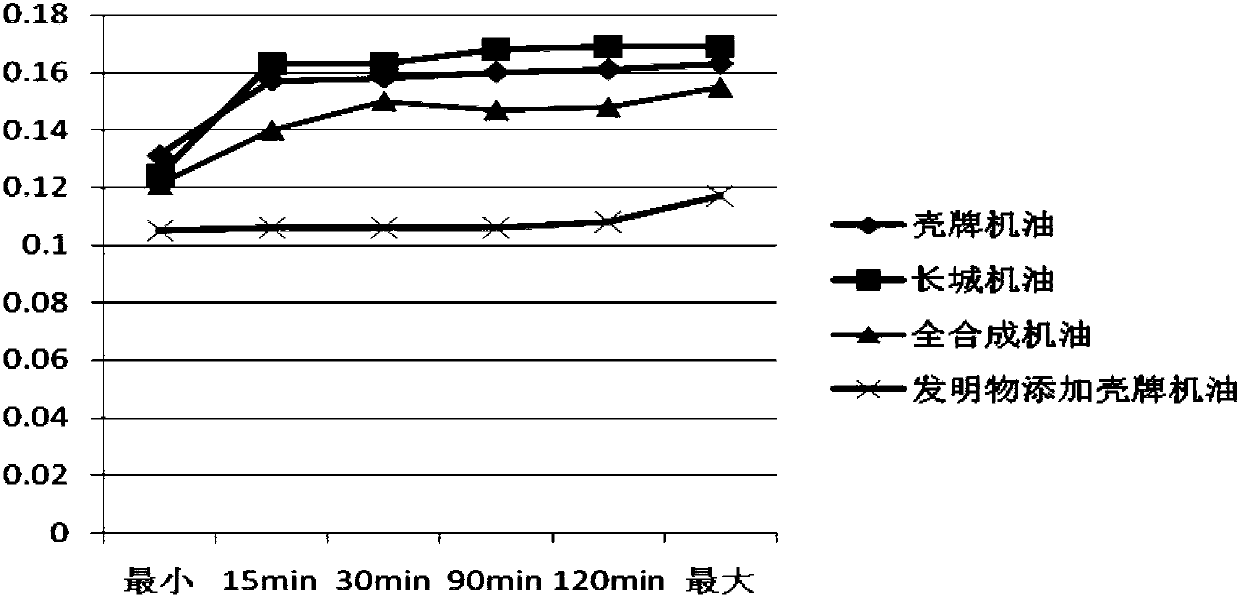

A composition and additive technology, applied in the directions of lubricating compositions, additives, petroleum industry, etc., can solve environmental problems such as metal corrosion, side effects, poor anti-wear effect, etc., and achieve the effect of good anti-wear and anti-friction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1, the additive composition that improves lubricant performance, by C 60 Fullerenes react with hydroxyl groups to give C 60 (OH) 8~15 or C 60 (OH) 24~26 , and then from the short-chain carboxylic acid C 1~5 Esterification product C obtained after COOH catalyzed esterification of hydroxyl groups 60 (OOC-R) 8~15或24~26 , as component A of this composition, it contains component B, component C, component D and component E at the same time. Component B is neopentyl polyol ester; component C is isooctyl sebacate; component D is dinonyl diphenylamine; component E is dimethylphenol paraester. The weight ratio of each component is: component A: 5, component B: 6, component C: 6, component D: 15; component E: 15.

Embodiment 2

[0054] Embodiment 2 is basically the same as Embodiment 1, but the weight ratio of each component is: component A: 0.1, component B: 2, component C: 2, component D: 10; component E: 10.

Embodiment 3

[0055] Embodiment 3 is basically the same as Embodiment 1, but the weight ratio of each component is: component A: 10, component B: 10, component C: 10, component D: 20; component E: 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com