Anti-yellowing cationic water-based polyurethane leather finishing agent

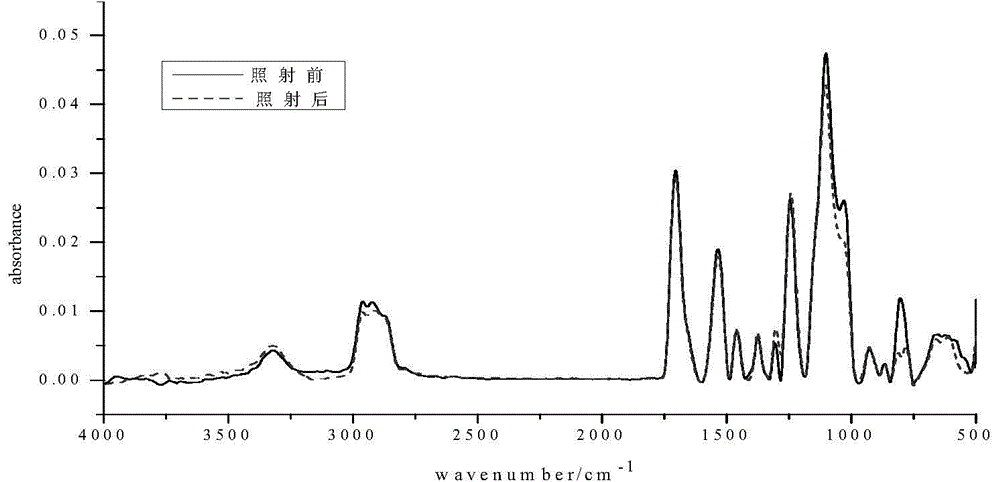

A water-based polyurethane and leather finishing agent technology, applied in leather surface treatment, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. Yellowing, affecting the use value and other problems, to achieve the effect of reducing the yellowing index, improving the resistance to yellowing, and reducing the time of yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

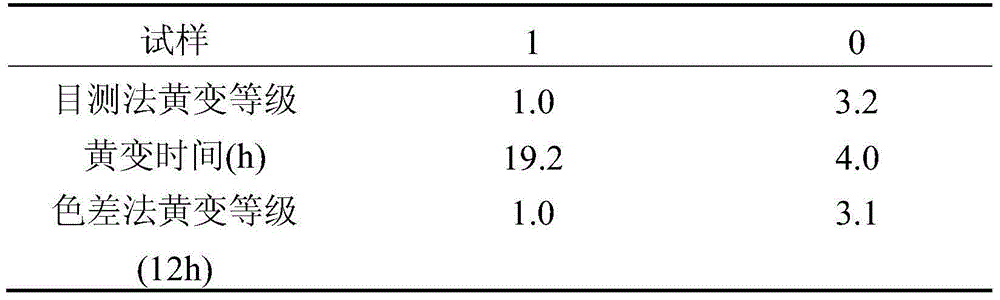

Embodiment 1

[0043] The mass percentage of the raw material of each component that prepares cationic waterborne polyurethane is as follows:

[0044] PPG: 47.1%; IPDI: 38.22%; antioxidant GA-80: 0.49%; anti-ultraviolet absorber UV-1577: 0.49%; crosslinking agent TMP: 1.88%; chain extender BDO: 2.26%; catalyst dibutyltin Dilaurate: 0.157%; emulsifier N-MDEA: 4.7%; neutralizer glacial acetic acid: 4.7%;

[0045] Synthesis of a yellowing-resistant cationic waterborne polyurethane leather finishing agent:

[0046] Add 30g of PPG into a container with mechanical stirring, thermometer and condenser, stir and dehydrate under vacuum at 90°C for 30min, cool down to 50°C and add 24.36g of IPDI, 0.315g of antioxidant GA80 and 0.315g of anti-ultraviolet absorber UV-1577, React at a constant temperature of 90°C for 2 hours; then add 1.20g of TMP and 1.44g of BDO for chain extension reaction, add acetone to dilute, then add 0.1g of catalyst dibutyltin dilaurate, react at a constant temperature of 85°C f...

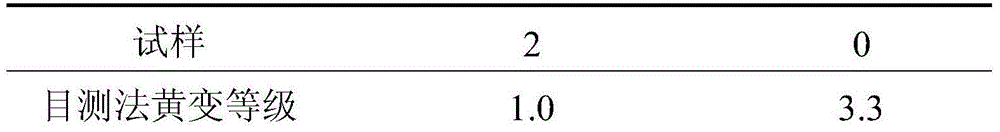

Embodiment 2

[0052]The mass percentage of the raw material of each component that prepares cationic waterborne polyurethane is as follows:

[0053] PPG: 51.6%; HDI: 28.69%; antioxidant GA-80: 0.91%; anti-ultraviolet absorber UV-1164: 0.91%; crosslinking agent TMP: 1.73%; chain extender BDO: 7.42%; catalyst dibutyltin Dilaurate: 0.144%; emulsifier N-MDEA: 4.32%; neutralizer glacial acetic acid: 4.32%;

[0054] Synthesis of a yellowing-resistant cationic waterborne polyurethane leather finishing agent:

[0055] Add 35.80g of PPG into a container with mechanical stirring, thermometer and condenser, stir and dehydrate under vacuum at 90°C for 30min, cool down to 50°C and add 19.92g of HDI, 0.63g of antioxidant GA80 and 0.63g of anti-ultraviolet absorber UV-1164 , 90°C constant temperature reaction for 2h; then add 1.20g TMP and 0.054gBDO for chain extension reaction, add acetone to dilute, then add 0.1g catalyst dibutyltin dilaurate, 85°C constant temperature reaction for 2h; then cool down t...

Embodiment 3

[0061] The mass percentage of the raw material of each component that prepares cationic waterborne polyurethane is as follows:

[0062] PTMG: 29.58%; HDI: 47.48%; antioxidant 1010: 1.76%; anti-ultraviolet absorber UV-1577: 1.76%; crosslinking agent N303: 5.05%; chain extender PG: 2.28%; catalyst dibutyltin dilaurel Ester: 0.281%; emulsifier PDEA: 6.17%; neutralizer glacial acetic acid: 5.61%;

[0063] Synthesis of a yellowing-resistant cationic waterborne polyurethane leather finishing agent:

[0064] Add 15.81g of PTMG into a container with mechanical stirring, thermometer and condenser, stir and dehydrate under vacuum at 90°C for 30min, cool down to 50°C and add 25.38g of HDI, 0.945g of antioxidant 1010 and 0.945g of anti-ultraviolet absorber UV-1577 , 90°C constant temperature reaction for 2 hours; then add 2.70g N303 and 1.22g PG for chain extension reaction, add acetone to dilute, then add 0.15g catalyst dibutyltin dilaurate, 85°C constant temperature reaction for 2h; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com