High density polyethylene resin for blow molding of middle-sized hollow container and preparation method thereof

A high-density polyethylene, hollow technology, applied in the field of modified high-density polyethylene resin and its preparation, can solve the problems of improving the appearance and color of the product, affecting the life of the product, and achieving outstanding oxidation resistance and excellent resistance to environmental stress cracking. , the effect of low yellow index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

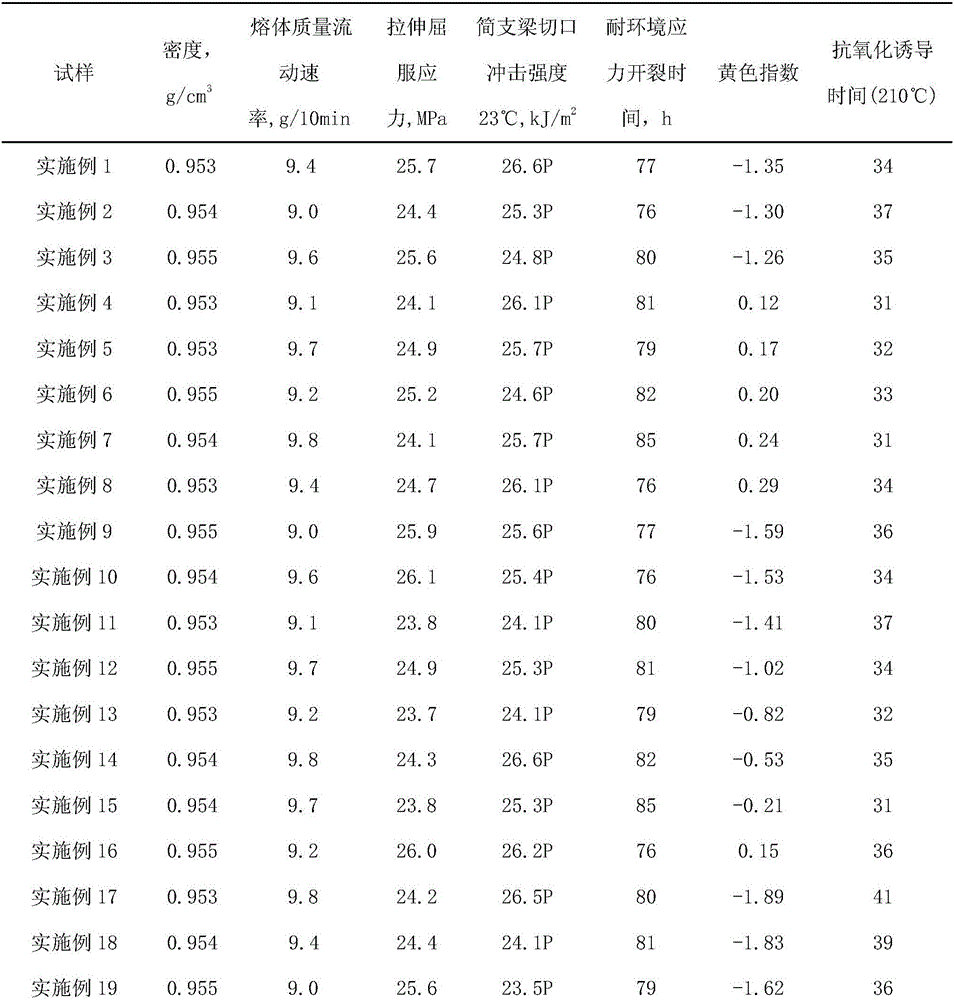

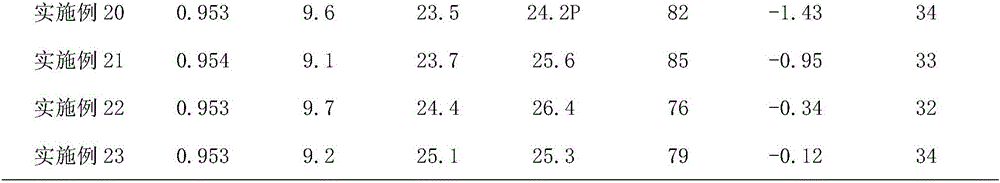

Examples

Embodiment 1

[0031] Expressed in parts by weight, 100 parts of ethylene hexene copolymerized high-density polyethylene base resin, 0.05 part of main antioxidant 3114, 0.15 part of compound auxiliary antioxidant (the addition of 626 is 0.01 part, the addition of P-EPQ 0.14 parts), 0.10 parts of light stabilizer 2020, 0.05 parts of halogen absorbent zinc stearate, add to a high-speed mixer and mix thoroughly, mix at 300r / min for 2 minutes and then 2000r / min for 0.5 minutes, then add twin-screw extruder Granulation is carried out in the extruder. During the granulation process, the temperature of each section of the extruder from the feed port to the head: 170°C, 180°C, 185°C, 190°C, 295°C, 200°C, 190°C, 185°C, 185°C, 175°C.

Embodiment 2

[0033] Expressed in parts by weight, 100 parts of ethylene hexene copolymerized high-density polyethylene base resin, 0.05 part of main antioxidant 3114, 0.14 part of compound auxiliary antioxidant (the addition of 626 is 0.02 part, the addition of P-EPQ 0.12 parts), 0.10 parts of light stabilizer 2020, 0.05 parts of halogen absorbent zinc stearate, add to a high-speed mixer and mix thoroughly, mix at 300r / min for 2 minutes and then 2000r / min for 0.5 minutes, then add twin-screw extruder The granulation is carried out in the extruder. The temperature of each section of the extruder from the feeding port to the die head during the granulation process: 173°C, 182°C, 187°C, 193°C, 198°C, 203°C, 193°C, 187°C, 187°C, 178°C.

Embodiment 3

[0035] Expressed in parts by weight, 100 parts of ethylene hexene copolymerized high-density polyethylene base resin, 0.05 part of main antioxidant 3114, 0.14 part of compound auxiliary antioxidant (the addition of 626 is 0.04 part, the addition of P-EPQ 0.10 parts), 0.10 parts of light stabilizer 2020, 0.05 parts of halogen absorber zinc stearate, add to high-speed mixer and mix thoroughly, mix at 600r / min for 1.5 minutes and then at 2000r / min for 0.5 minutes, then add twin-screw extruder The granulation is carried out in the extruder, the temperature of each section of the extruder from the feeding port to the die head during the granulation process: 175°C, 185°C, 190°C, 195°C, 200°C, 205°C, 195°C, 190°C, 190°C, 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com