Preparation method of yellowing-resistant abs resin

An ABS resin and anti-yellowing technology, which is applied in the field of preparation of long-acting anti-yellowing ABS resin, can solve the problems of limited application, low whiteness value, high price of anti-yellowing agent, etc., and improve the anti-yellowing performance and thermal stability, and the effect of improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

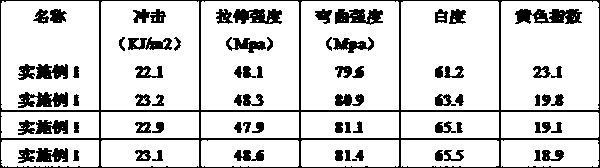

Examples

Embodiment 1

[0015] (1) 500g of polybutadiene latex (PBL, 300nm, 60wt%), 16g of disproportionated rosin soap aqueous solution with a mass fraction of 25wt%, 3g of potassium carbonate, 0.8g of initiator cumene hydroperoxide, 0.5g The reducing agent ferrous sulfate of 1 g, the co-reducing agent glucose of 1 g, the chelating agent sodium pyrophosphate of 1 g, and the water of 538 g are placed in the reaction kettle, and the room temperature is replaced with nitrogen twice, and the temperature is rapidly raised to 65° C.;

[0016] (2) After the temperature of the reactor is stabilized for 10 minutes, slowly add 150 g of styrene and 50 g of acrylonitrile dropwise to the reactor, and then add 0.2 g of the initiator cumene hydroperoxide dropwise to the reactor again after the addition is completed. The temperature of the reaction kettle was raised to 80°C and kept at a constant temperature for 0.5 hours, and then the temperature of the reaction kettle was lowered to below 50°C, and 10 g of special...

Embodiment 2

[0020] (1) 500g of polybutadiene latex (PBL, 300nm, 60wt%), 16g of disproportionated rosin soap aqueous solution with a mass fraction of 25wt%, 3g of potassium carbonate, 0.8g of initiator cumene hydroperoxide, 0.5g The reducing agent ferrous sulfate of 1 g, the co-reducing agent glucose of 1 g, the chelating agent sodium pyrophosphate of 1 g, and the water of 538 g are placed in the reaction kettle, and the room temperature is replaced with nitrogen twice, and the temperature is rapidly raised to 65° C.;

[0021] (2) After the temperature of the reactor is stabilized for 10 minutes, slowly add 150g of styrene, 50g of acrylonitrile, and 5g of epoxy vinyl monomer glycidyl methacrylate dropwise to the reactor, and then pour it into the reactor again Add 0.2g of initiator cumene hydroperoxide dropwise, raise the temperature of the reactor to 80°C for 0.5 hours, then reduce the temperature of the reactor to below 50°C, and add 10g of special antioxidant emulsion to obtain the ABS g...

Embodiment 3

[0025] (1) 500g of polybutadiene latex (PBL, 300nm, 60wt%), 16g of disproportionated rosin soap aqueous solution with a mass fraction of 25wt%, 3g of potassium carbonate, 0.8g of initiator cumene hydroperoxide, 0.5g The reducing agent ferrous sulfate of 1 g, the co-reducing agent glucose of 1 g, the chelating agent sodium pyrophosphate of 1 g, and the water of 538 g are placed in the reaction kettle, and the room temperature is replaced with nitrogen twice, and the temperature is rapidly raised to 65° C.;

[0026] (2) After the temperature of the reactor is stabilized for 10 minutes, slowly add 150g of styrene, 50g of acrylonitrile, and 10g of epoxy vinyl monomer glycidyl methacrylate dropwise to the reactor, and then pour it into the reactor again Add 0.2g of initiator cumene hydroperoxide dropwise, raise the temperature of the reactor to 80°C for 0.5 hours, then reduce the temperature of the reactor to below 50°C, and add 10g of special antioxidant emulsion to obtain the ABS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com