Liquid polybutadiene, preparation method and application thereof, composition, polymer coating, adhesive and cross-linking agent

A liquid polybutadiene and initiator technology, applied in the direction of conjugated diene adhesives, adhesives, adhesive types, etc., can solve the problem of difficult to achieve low molecular weight liquid polybutadiene preparation, wide molecular weight distribution, peeling Low strength and other problems, to achieve good application prospects, narrow molecular weight distribution, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] According to the second aspect of the present invention, the present invention provides a method for preparing liquid polybutadiene, the method comprising: under anionic polymerization conditions, 1,3-butadiene and structure regulator and organic lithium The initiator is contacted in a polymerization solvent to obtain a polymerization reaction mixture liquid containing polybutadiene, and the contact is carried out at a temperature not higher than 40°C.

[0048] According to the preparation method of the present invention, the structure regulator contains component A and component B, the component A is one or two or more selected from ethers and amines, and the component B is selected from alkalis One or more than two kinds of metal alkoxides.

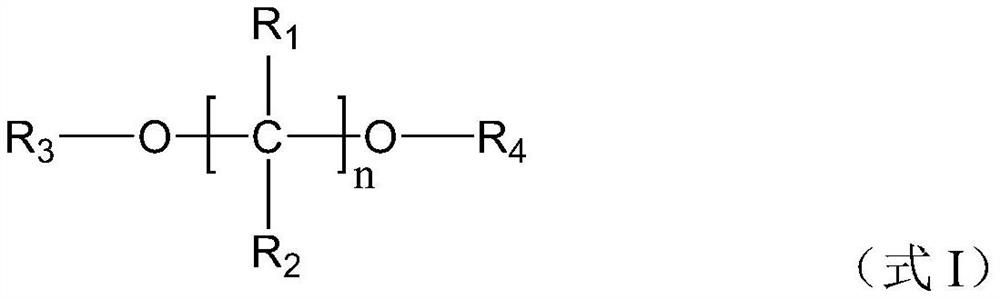

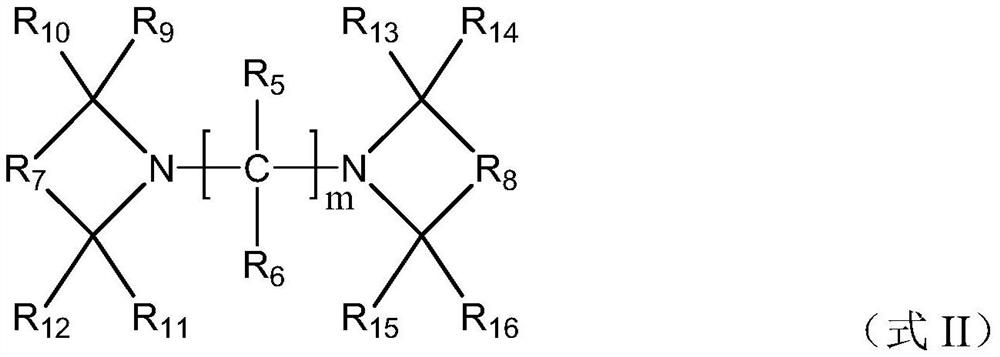

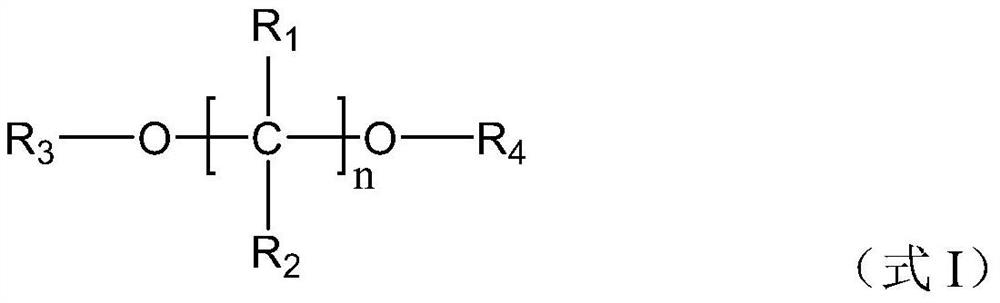

[0049] According to the preparation method of the present invention, the component A is one or more selected from the compound shown in formula I and the compound shown in formula II:

[0050]

[0051] In formula I, R 1 and ...

Embodiment 1

[0119] This example is used to illustrate the liquid polybutadiene of the present invention and its preparation method.

[0120] (1) Under nitrogen protection, add cyclohexane, structure regulator 1, structure regulator 2, 1,3-butadiene (see Table 1 for the type and consumption, and the consumption listed in the table) in the 5L reactor All are measured with pure compound), the control reactor temperature is below 10 ℃, in the 5L reactor, add the n-butyllithium of design amount (consumption is shown in Table 1, and the consumption listed in the table is all measured with pure compound); And in the table Carry out anionic polymerization under the temperature and reaction pressure listed in 1 to obtain a polymerization reaction mixture containing polybutadiene.

[0121] (2) add water and acid (concrete consumption and the kind of acid are listed in table 2 in the polymerization reaction mixed solution that step (1) obtains, and the consumption listed in the table is all metered ...

Embodiment 2-7

[0124] Examples 2-7 are used to illustrate the liquid polybutadiene of the present invention and its preparation method.

[0125] Embodiment 2-7 adopts the method identical with embodiment 1 to prepare liquid polybutadiene, difference is, under the condition listed in table 1, prepare the composition PB2-PB7 that contains liquid polybutadiene according to the present invention, Among them, the structural property parameters of the prepared liquid polybutadiene are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dynamic viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com