A kind of halogen-free flame-retardant modified hydrocarbon resin and preparation method thereof

A hydrocarbon resin and modification technology, which is applied in the field of halogen-free flame-retardant modified hydrocarbon resin and its preparation, can solve the problem of harm to human health and the ecological environment, and affect the electrical and mechanical properties, dielectric constant and High dielectric loss and other problems, to achieve the effect of narrow reaction residence time, simple process and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0055] A halogen-free flame-retardant modified hydrocarbon resin, the halogen-free flame-retardant modified hydrocarbon resin is a hydrocarbon resin, a double-bond-containing phosphate flame retardant, an initiator and a solvent are mixed and reacted through a microchannel reactor and removed Made from some solvents;

[0056] The hydrocarbon resin is styrene-butadiene resin, polybutadiene resin, polyisobutadiene resin, polyprene resin, styrene-butadiene copolymer, styrene-isobutadiene copolymer, styrene - divinylbenzene copolymer, polystyrene, 2-methylpolystyrene, 3-methylpolystyrene, 4-methylpolystyrene, 2,4-diisopropylpolystyrene, 2, One or a mixture of two or more of 4-dimethylpolystyrene, ethylene-propylene-diene copolymer, and cycloolefin copolymer;

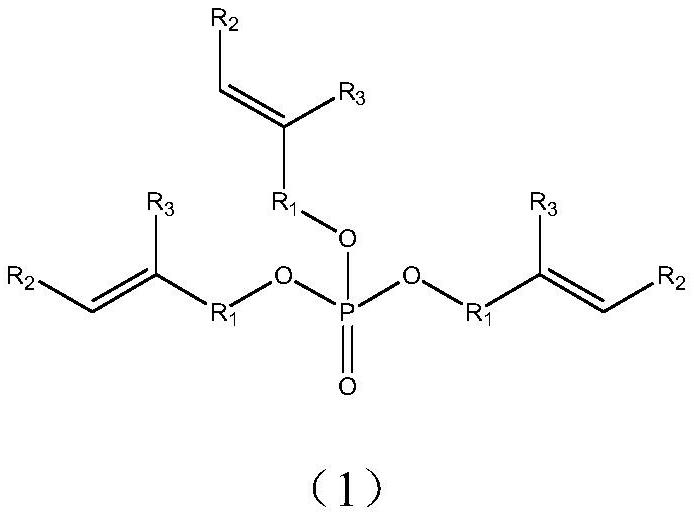

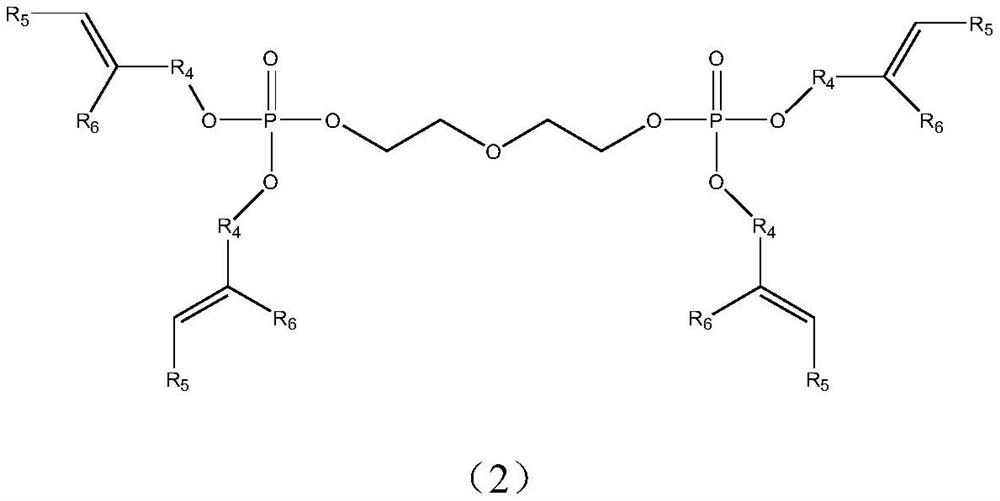

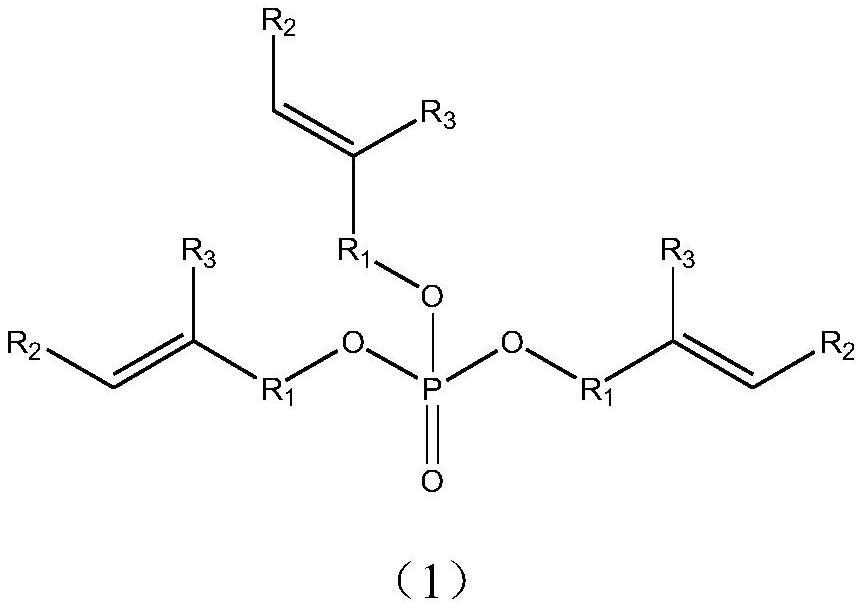

[0057] The double-bond-containing phosphate flame retardant is one or a mixture of two or more of the following formula (1) and formula (2):

[0058]

[0059] In formula (1): R 1 for -CH 2 -, -C 3 h 6 -, -C 2 h 4 ...

Embodiment 3

[0065] A halogen-free flame-retardant modified hydrocarbon resin, the initiator is dicumyl peroxide, di-tert-butyl peroxide, tert-butyl peroxybenzoate, dicyclohexyl peroxydicarbonate, isopropyl One or more mixtures of benzene hydroperoxide and azobisisobutyronitrile.

Embodiment 4

[0067] A halogen-free flame-retardant modified hydrocarbon resin, the microchannel reactor is Corning Microchannel Reactor, Shandong Haomai Microchannel Reactor, Suzhou Wenhao Microreactor, Shanghai Sanwei Microchannel Reactor, Mijing Microchannel Reactor Any one of the Science and Technology Microchannel Reactor, the Gongyi Yuhua Microchannel Reactor, and the Flucker Microchannel Reactor, and others are the same as those in Example 2, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com