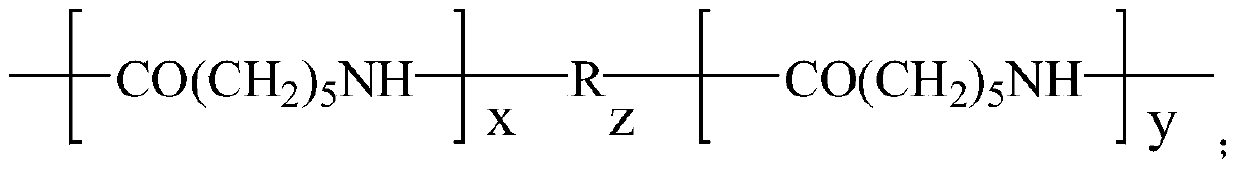

Permanent flame retardant nylon 6 material and preparation method thereof

A flame-retardant nylon, permanent technology, applied in the field of flame-retardant nylon synthesis, can solve the problems of small impact on performance, monotonous melting point, loss of fabric strength, etc. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a permanent flame-retardant nylon 6 material, specifically comprising the following steps:

[0037] (1) Mix the flame retardant DDP, hexamethylenediamine and water, mix evenly at 50°C for 2 hours under the protection of nitrogen, then stir and react at 90°C for 2 hours, then raise the temperature to 150°C for further polymerization, and finally decompress and vacuumize, and react Finish generating flame retardant prepolymer, it is viscous liquid, number average molecular weight Mn is 1.8×10 3 , the molar ratio of flame retardant DDP, hexamethylenediamine and water is 1:1.1:2, and the two ends of the obtained flame retardant prepolymer are active end groups of a carboxyl group and an amine group respectively;

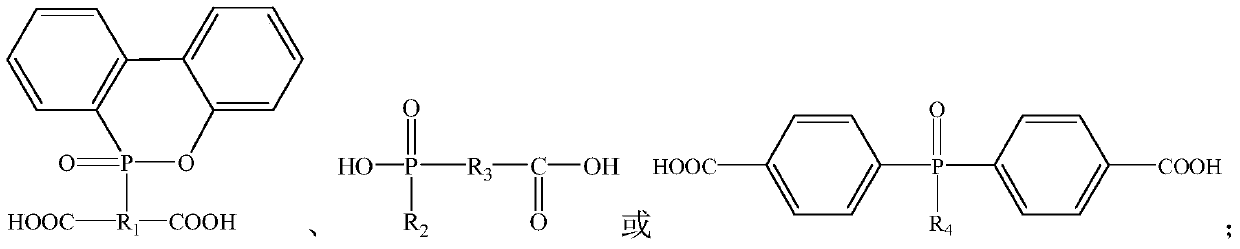

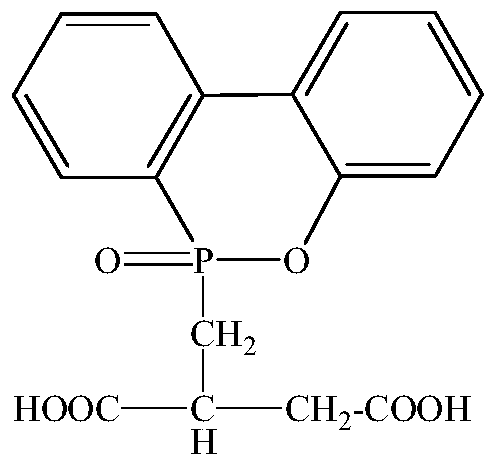

[0038] The structure of the flame retardant is:

[0039]

[0040] (2) 90.7 parts by mass of caprolactam, 4.0 parts by mass of water and 0.3 parts by mass of adipic acid are added to the reactor, and N 2 Exhaust the air in the kettle, s...

Embodiment 2

[0049] A preparation method of a permanent flame-retardant nylon 6 material, specifically comprising the following steps:

[0050] (1) Mix the flame retardant CEPPA, hexamethylenediamine and water, mix evenly at 80°C for 3 hours under the protection of nitrogen, then stir and react at 130°C for 3 hours, then raise the temperature to 180°C for further polymerization, and finally decompress and vacuumize, react Finish generating flame retardant prepolymer, it is semi-solid, number average molecular weight Mn is 2.5 * 10 3 , the molar ratio of flame retardant CEPPA, hexamethylenediamine and water is 1:1.2:2.5, and the two ends of the obtained flame retardant prepolymer are respectively a carboxyl group and an amine active end group;

[0051] The structure of the flame retardant is:

[0052]

[0053] (2) 84.0 parts by mass of caprolactam, 5 parts by mass of water and 1 part by mass of adipic acid are added to the reactor, and N 2 Exhaust the air in the kettle, stir at a speed...

Embodiment 3

[0062] A preparation method of a permanent flame-retardant nylon 6 material, specifically comprising the following steps:

[0063] (1) Mix the flame retardant BCPPO, hexamethylenediamine and water, mix evenly at 60°C for 2.5 hours under the protection of nitrogen, then stir and react at 95°C for 2 hours, then raise the temperature to 160°C for further polymerization, and finally vacuumize under reduced pressure, At the end of the reaction, a flame retardant prepolymer is generated, which is a viscous liquid with a number average molecular weight Mn of 2.8×10 3 , the molar ratio of flame retardant BCPPO, hexamethylenediamine and water is 1:1.2:2.1, and the two ends of the obtained flame retardant prepolymer are respectively a carboxyl group and an amine active end group;

[0064] The structure of the flame retardant is:

[0065]

[0066] (2) 92.9 parts by mass of caprolactam, 0.8 parts by mass of water and 0.8 parts by mass of adipic acid are added to the reactor, and N 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com