Adhesive-bonded panel made of bamboo and wood and its prodn. method

A production method and technology for plywood, which are applied in the bonding of wooden veneers, chemical instruments and methods, adhesives, etc., can solve the problems of high cost, low product quality and poor stability of bamboo plywood, and reduce the amount of glue used, heat The effect of short pressing time and reduced processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

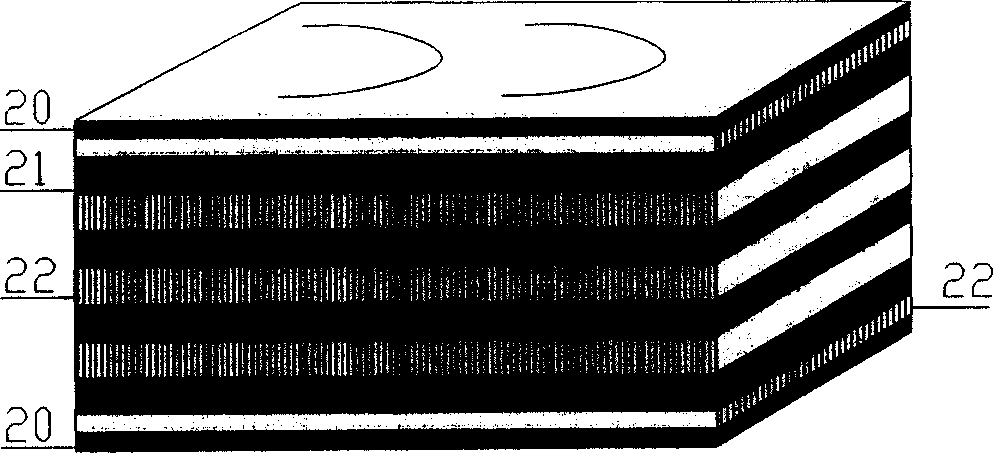

[0040] A kind of 11-layer bamboo-wood plywood, the 1st and 11th layers are bamboo mats, the thickness is 1.0 mm, as attached figure 1 20 in; the 3rd, 5th, 7th, and 9th layers are bamboo screens, and the arrangement direction of the bamboo screens in the bamboo-wood plywood is that the length direction of the bamboo sheets forming the bamboo screen is consistent with the length direction of the bamboo-wood plywood (hereinafter referred to as the lengthwise direction of the bamboo-wood plywood). Core bamboo curtain, the length direction of the bamboo sheets that make up the bamboo curtain is perpendicular to the length direction of the bamboo plywood, referred to as short core bamboo curtain), the thickness is 2.2 mm, such as figure 1 21 in; the 2nd, 4th, 6th, 8th, and 10th floors are wood veneers, eucalyptus veneers, such as figure 1 In 22, the wood grain direction of the 2nd and 10th eucalyptus veneer is consistent with the length direction of the bamboo plywood (hereinafter r...

Embodiment 2

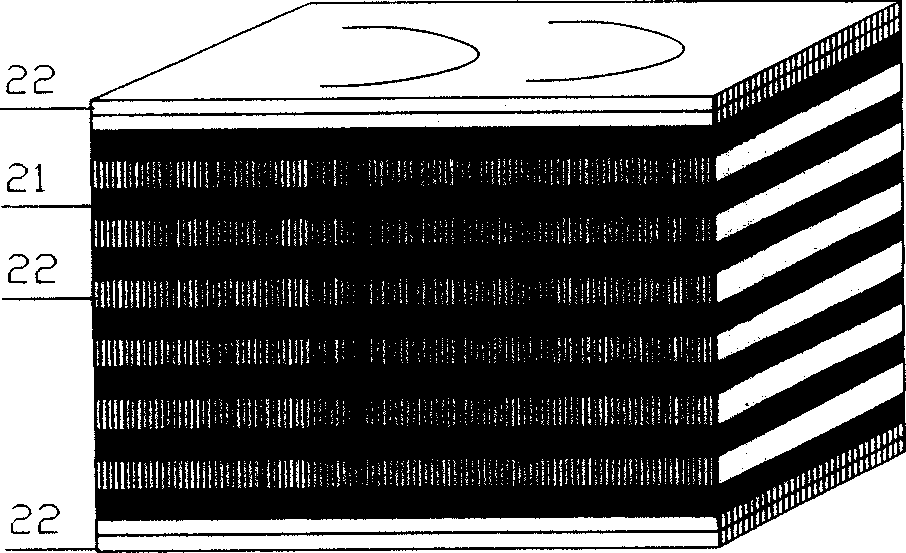

[0042]A kind of 17-layer bamboo-wood plywood; the 3rd, 5th, 7th, 9th, 11th, 13th, and 15th layers are bamboo curtains, all of which are long-core bamboo curtains with a thickness of 2.4 mm, such as figure 2 21 of them; the 1st, 2nd, 4th, 6th, 8th, 10th, 12th, 14th, 16th, and 17th floors are birch veneers, such as figure 2 In 22, the wood grain of the birch veneer on the surface is consistent with the length direction of the bamboo plywood (hereinafter referred to as the surface floor), the 2nd and 17th layers are birch long core boards, and the 4th, 6th, 8th, and 10th layers are birch long core boards. , 12, 14, and 16 are short birch core boards with a thickness of 1.6 mm. The thickness of the blank is 32.8 mm. Dry the bamboo curtains and birch veneers with a moisture content of not more than 10%; apply glue to the 2nd, 4th, 6th, 8th, 10th, 12th, 14th, and 16th birch veneers, and use waterproof phenolic glue, which meets AQIS requirements Insect repellent, the amount of g...

Embodiment 3

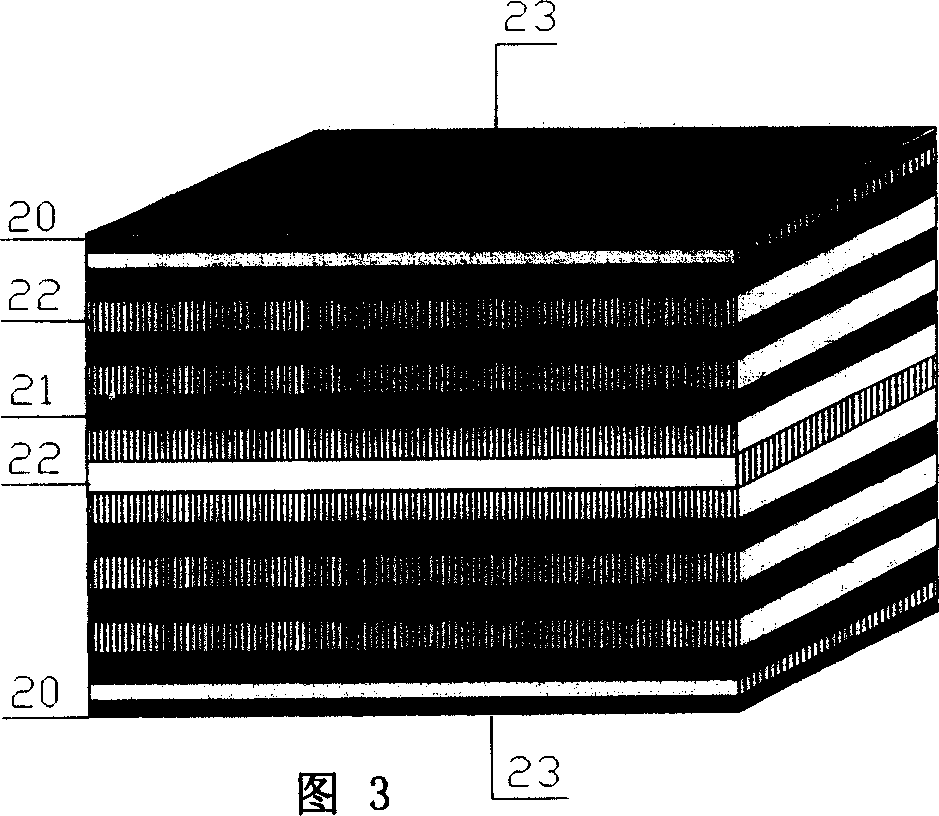

[0044] A 17-ply bamboo plywood with phenolic glue impregnated paper on and under the bamboo plywood. The 1st and 17th floors are bamboo mats with a thickness of 1.0mm, as shown in Figure 3, 20, and the 3rd, 5th, 7th, 11th, 13th, and 15th floors are bamboo curtains, all of which are long-core bamboo curtains with a thickness of 2.4mm. 21 in Fig. 3; the 2nd, 4, 6, 8, 9, 10, 12, 14, and 16 layers are birch veneers with a thickness of 1.7 mm, 22 in Fig. 3; among them, the 2nd, 10, 16 It is birch long core board, No. 4, 6, 8, 10, 12, 14 is birch short core board. Bamboo plywood with phenolic impregnated paper underneath, such as Figure 4 23 of them. The thickness of the blank is 32.8 mm. Dry the bamboo mats, bamboo curtains, and birch veneers with a moisture content of no more than 10%; apply glue to the 2nd, 4th, 6th, 8th, 10th, 12th, 14th, and 16th birch veneers, use waterproof phenolic glue, and add them to the glue Insect repellant that meets the requirements of AQIS, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com