Bendable thermosetting resin impregnated paper high-pressure laminate

A resin-impregnated, laminated board technology, used in the field of decorative materials, can solve the problems of thick thickness, poor bending performance, and inability to use cladding, and achieve the effects of paint-free, short hot-pressing time, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

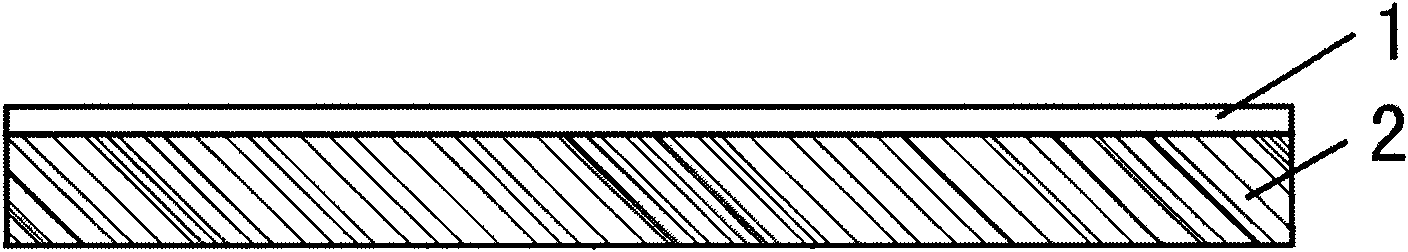

[0022] Embodiment one: if figure 1 As shown, a flexible thermosetting resin impregnated paper high-pressure laminated board, which includes an impregnated film paper facing layer 1, a veneer balance layer 2, and the impregnated film paper facing layer 1 and veneer balance layer 2 are subjected to high temperature Thin high-pressure laminates are formed by heat-compression lamination.

[0023] Impregnated adhesive film paper finish layer 1 is the wood-based panel surface finish layer formed by impregnating special paper with initial polycondensate or prepolymer of synthetic resin, and then drying. The synthetic resin may be selected from urea-formaldehyde resin, phenol-formaldehyde resin, modified melamine resin, guanamine resin, or dipropylene phthalate resin. The synthetic resin in this embodiment has selected urea-formaldehyde resin for use.

[0024] The veneer balance layer 2 can be selected from natural veneer, natural veneer, reconstituted decorative veneer, veneer obta...

Embodiment 2

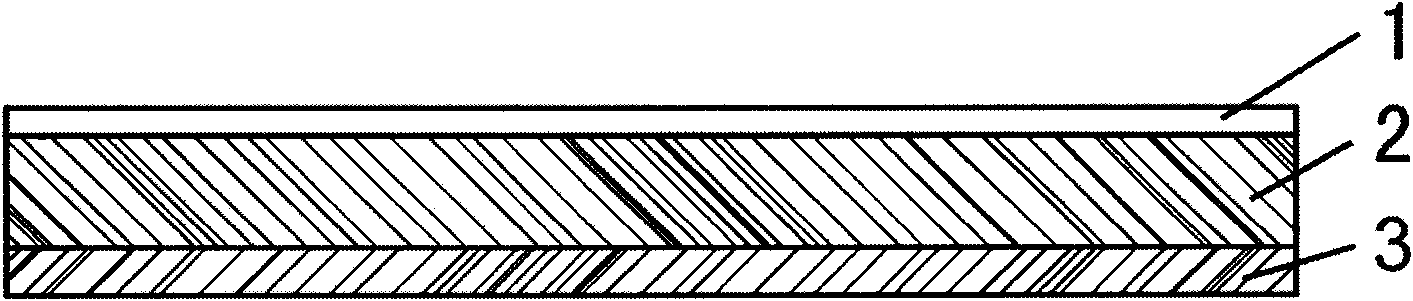

[0027] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that natural veneer is selected as the veneer balance layer 2 , and the bottom of the veneer balance layer 2 is also provided with kraft paper 3 .

Embodiment 3

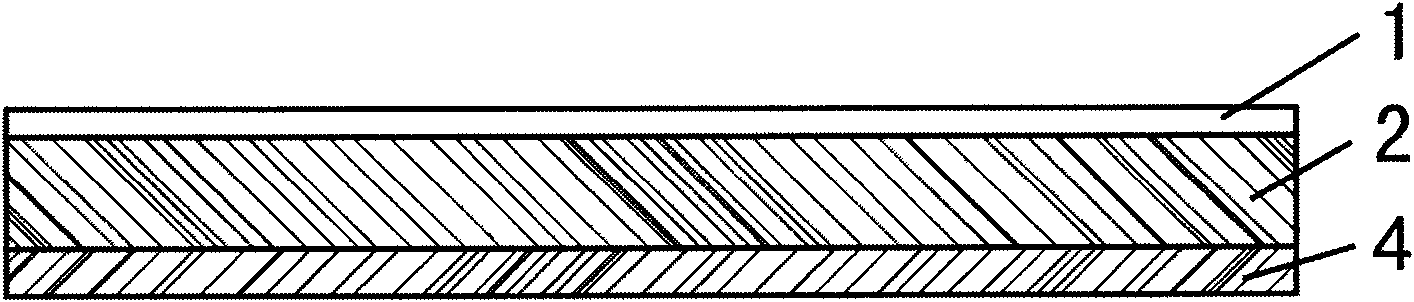

[0029] Such as image 3 As shown, the difference between this embodiment and the first embodiment is that: the bottom of the veneer balance layer 2 is also provided with a non-woven fabric 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com