Preparation method of composite modified adhesive and manufacturing method of anti-damp fiberboard

A compound modification and manufacturing method technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of complex synthesis process conditions and equipment, difficulty in meeting the high moisture-proof and water-resistant performance requirements of fiberboard, and expensive raw materials. , to achieve the effect of solving unstable waterproof performance and easy mildew, simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

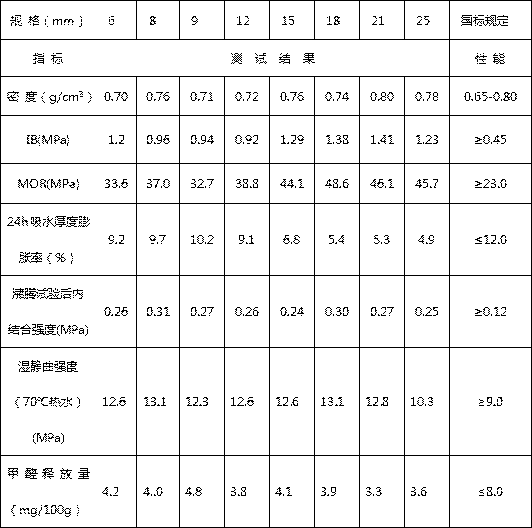

Embodiment 1

[0021] A preparation method of a composite modified adhesive, the main points of which are: 70 parts of environmentally friendly urea-formaldehyde resin or melamine-modified urea-formaldehyde resin glue, 5 parts of potassium sorbate, 5 parts of polyol, 5 parts of isocyanate, 15 parts of water, Mix evenly according to the weight ratio; among them, the environmentally friendly urea-formaldehyde resin or melamine-modified urea-formaldehyde resin glue is E 1 Grade or E 0 Grade, density 1.18-1.19g / cm 3 , the viscosity is 16-18S (20℃, T4 cup), the solid content is 52.0-53.0%, the pH value is 7.2-7.5, and the free formaldehyde is ≤0.15%; the polyol is ethylene glycol or glycerol, and the isocyanate is di Phenylmethane diisocyanate or isocyanate gum.

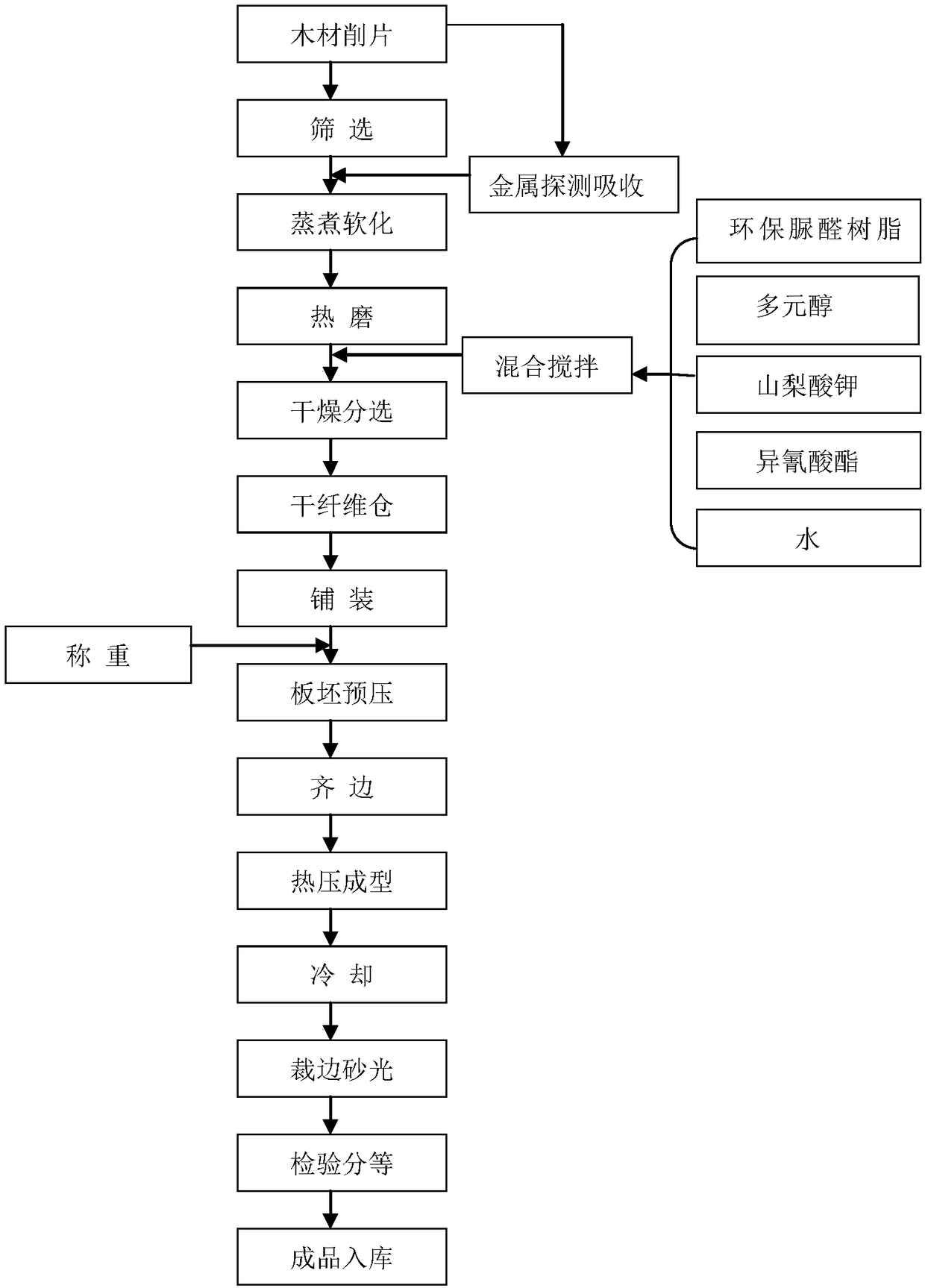

[0022] A method for manufacturing a moisture-proof and water-resistant fiberboard, the key of which is to carry out the following steps:

[0023] After the compound modified adhesive is prepared, follow the production process for pro...

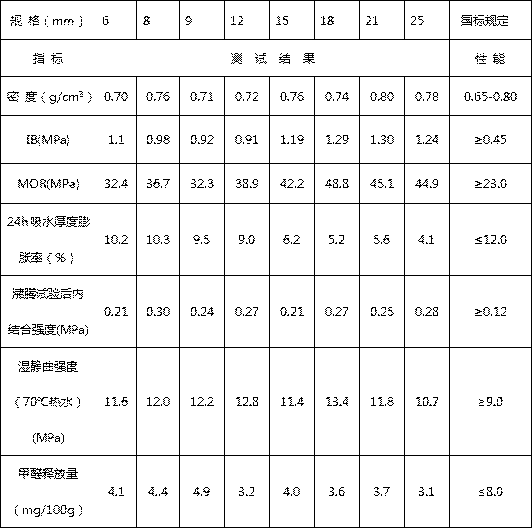

Embodiment 2

[0029] A preparation method of a composite modified adhesive, the main points of which are: 80 parts of environmentally friendly urea-formaldehyde resin or melamine-modified urea-formaldehyde resin glue, 10 parts of potassium sorbate, 2 parts of polyol, 0.5 parts of isocyanate, 7.5 parts of water, Mix evenly according to the weight ratio;

[0030] Among them, the quality of environmentally friendly urea-formaldehyde resin or melamine-modified urea-formaldehyde resin is E 1 Grade or E 0 Grade: Density 1.20-1.21g / cm 3 , the viscosity is 22-25S (20°C, T4 cup), the solid content is 52.0-53.0%, the pH value is 8.2-8.5, and the free formaldehyde is less than or equal to 0.20%. The polyol is a mixture of ethylene glycol and glycerol, and the isocyanate is a mixture of diphenylmethane diisocyanate and isocyanate glue.

[0031] A method for manufacturing a moisture-proof and water-resistant fiberboard, the key of which is to carry out the following steps:

[0032] After the prepara...

Embodiment 3

[0037] A preparation method of a composite modified adhesive, the key points of which are: 75 parts of environmentally friendly urea-formaldehyde resin or melamine-modified urea-formaldehyde resin glue, 7.5 parts of potassium sorbate, 3.5 parts of polyol, 2.5 parts of isocyanate, 11.5 parts of water, Mix evenly by weight.

[0038] Among them, the quality of environmentally friendly urea-formaldehyde resin or melamine-modified urea-formaldehyde resin is E 1 Grade or E 0 Grade: Density 1.20-1.21g / cm 3, the viscosity is 20-22S (20°C, T4 cup), the solid content is 52.0-53.0%, the pH value is 8.0-8.2, and the free formaldehyde is less than or equal to 0.18%. Among them, the polyol is a mixture of three kinds of ethylene glycol, propylene glycol and dipropylene glycol. The isocyanate is obtained by mixing diphenylmethane diisocyanate, isocyanate glue and emulsifiable isocyanate.

[0039] A method for manufacturing a moisture-proof and water-resistant fiberboard, the key of which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com