Preparation method of low-density fiberboards

A fiberboard and low-density technology, which is applied in the field of low-density fiberboard preparation, can solve the problems that furniture boards or load-bearing boards cannot be used, performance indicators cannot be reached, and nail-holding force is poor, so as to reduce manpower consumption and transportation costs. The effect of short pressing time and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

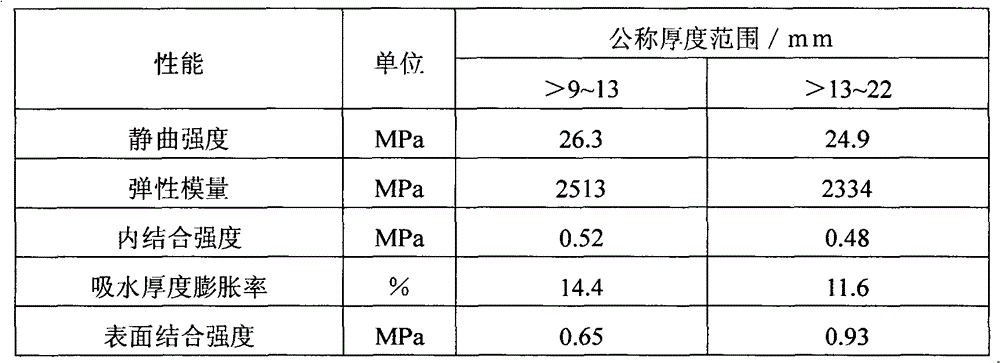

[0012] A preparation method for low-density fiberboards, comprising steps of wood chipping, fiber preparation, fiber sizing, paving, pre-pressing, heat pressing, and wool board treatment steps, in the fiber sizing step, the weight ratio of fiber and adhesive is 10:2, that is, adding 2 parts of adhesive for every 10 parts of fiber by weight, said adhesive is composed of 90% by weight of melamine-modified urea-formaldehyde resin adhesive and 10% of melamine-formaldehyde resin adhesive, and said melamine-modified The molar ratio of formaldehyde to urea in the urea-formaldehyde resin adhesive is 1.2:1, and the weight ratio of melamine to formaldehyde in the melamine-formaldehyde resin adhesive is 0.9:1; the process parameters in the hot-pressing step are: the hot-pressing temperature is 150-210°C , the closing time of the hot press is 3 seconds, the hot pressing time is 60 seconds, the hot pressing pressure is 0-2.8 MPa, and the hot pressing coefficient is 6 seconds / mm. After test...

Embodiment 2

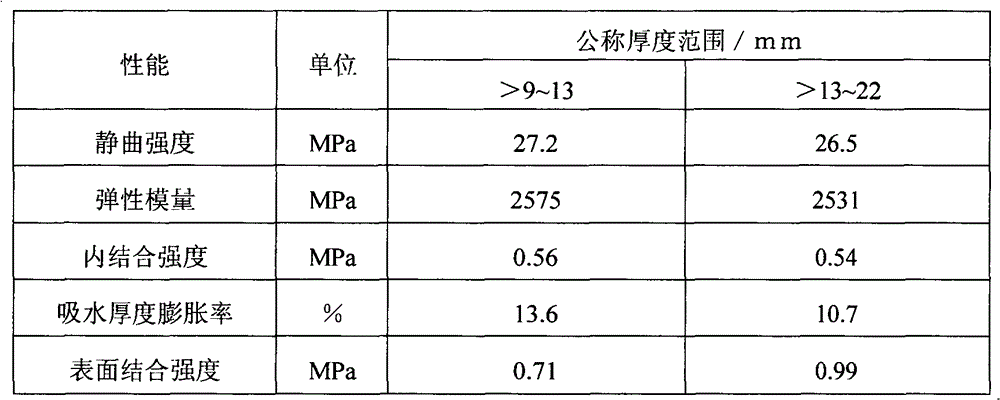

[0015] A preparation method for low-density fiberboards, comprising steps of wood chipping, fiber preparation, fiber sizing, paving, pre-pressing, heat pressing, and wool board treatment steps, in the fiber sizing step, the weight ratio of fiber and adhesive is 10:1.2, that is, adding 1.2 parts of adhesive per 10 parts of fiber by weight, said adhesive is composed of 99% by weight of melamine-modified urea-formaldehyde resin adhesive and 1% of melamine-formaldehyde resin adhesive, said melamine-modified The molar ratio of formaldehyde to urea in the urea-formaldehyde resin adhesive is 1.2:1, and the weight ratio of melamine to formaldehyde in the melamine-formaldehyde resin adhesive is 0.9:1; the process parameters in the hot-pressing process are: the hot-pressing temperature is 160-210°C , the closing time of the hot press is 8 seconds, the hot pressing time is 100 seconds, the hot pressing pressure is 0-2.8 MPa, and the hot pressing coefficient is 10 seconds / mm. After testin...

Embodiment 3

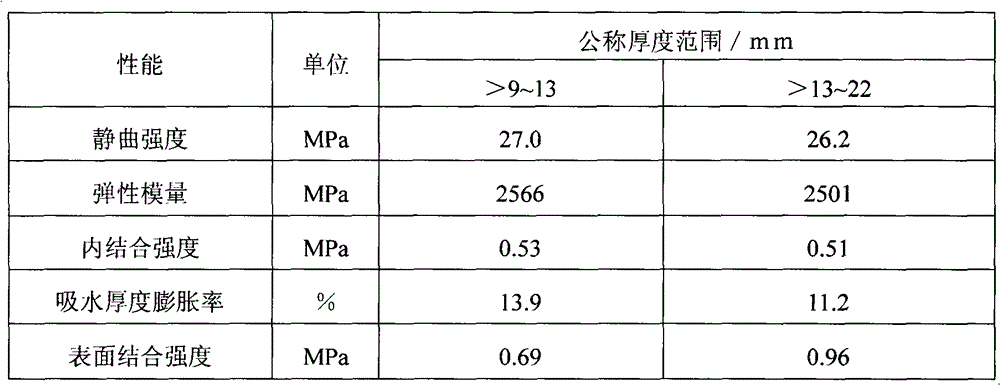

[0018] A preparation method for low-density fiberboards, comprising steps of wood chipping, fiber preparation, fiber sizing, paving, pre-pressing, heat pressing, and wool board treatment steps, in the fiber sizing step, the weight ratio of fiber and adhesive is 10:1.5, that is, adding 1.5 parts of adhesive per 10 parts of fiber by weight, said adhesive is composed of 95% by weight of melamine-modified urea-formaldehyde resin adhesive and 5% of melamine-formaldehyde resin adhesive, said melamine-modified The molar ratio of formaldehyde to urea in the urea-formaldehyde resin adhesive is 1.2:1, and the weight ratio of melamine to formaldehyde in the melamine-formaldehyde resin adhesive is 0.9:1; the process parameters in the hot-pressing process are: the hot-pressing temperature is 170-210°C , the closing time of the hot press is 6 seconds, the hot pressing time is 90 seconds, the hot pressing pressure is 0-2.8 MPa, and the hot pressing coefficient is 9 seconds / mm. After testing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com