Method for preparing lignin-based adhesive through enzymatic modification

A lignin-based and adhesive technology, applied in the direction of lignin adhesives, adhesives, adhesive additives, etc., can solve the problems of limited mechanical strength, high enzyme usage, limited modification efficiency, etc., to improve mechanical strength and water resistance, and the effect of improving the degree of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

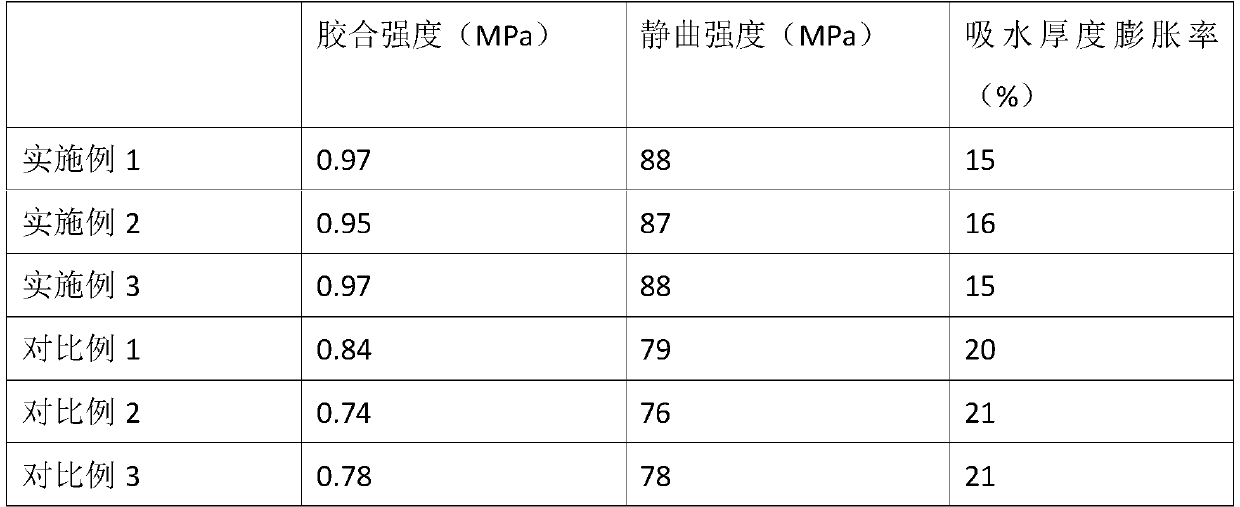

Examples

Embodiment 1

[0023] Mix 50g alkali lignin with 10g compound enzyme, 5g vanillin, 2g 1-hydroxybenzotriazole, 10mL 0.28mM ABTS, 2g Triton X-100, then add acetic acid / sodium acetate buffer to adjust the pH of the reaction solution to 3.6 , and reacted for 3.5 hours at a temperature of 51°C to obtain a lignin-based adhesive prepared by enzymatic modification; alkali lignin was extracted from papermaking waste liquid. The compound enzyme is composed of 20% lignin peroxidase, 20% manganese peroxidase and 60% laccase, and the percentages are mass fractions.

[0024] The application of the aforementioned enzyme-modified lignin-based adhesive comprises the following steps:

[0025] (1) Evenly coating the enzymatically modified lignin-based adhesive on the surface of the veneer to form a plywood slab;

[0026] (2) The plywood slab is transferred to the hot press for hot pressing;

[0027] (3) Transfer the hot-pressed plywood into a cold press for cold pressing.

[0028] In step (1), the amount of...

Embodiment 2

[0030] Mix 55g alkali lignin with 12g compound enzyme, 5g vanillin, 2g 1-hydroxybenzotriazole, 10mL 0.28mM ABTS, 2g Triton X-100, then add acetic acid / sodium acetate buffer to adjust the pH of the reaction solution to 3.6 , and reacted for 3.3 hours at a temperature of 51 ° C to obtain a lignin-based adhesive prepared by enzymatic modification; alkali lignin was extracted from papermaking waste liquid. The compound enzyme is composed of 20% lignin peroxidase, 20% manganese peroxidase and 60% laccase, and the percentages are mass fractions.

[0031] The application of the aforementioned enzyme-modified lignin-based adhesive comprises the following steps:

[0032] (1) Evenly coating the enzymatically modified lignin-based adhesive on the surface of the veneer to form a plywood slab;

[0033] (2) hot pressing treatment;

[0034] (3) cold pressing treatment.

[0035] In step (1), the amount of glue applied to the enzymatically modified lignin-based adhesive is 0.07g / cm 2 ; Glu...

Embodiment 3

[0037] Mix 50g alkali lignin with 10g complex enzyme, 5g vanillin, 2g 1-hydroxybenzotriazole, 10mL 0.28mM ABTS, 2g Triton X-100, and then add acetic acid / sodium acetate buffer to adjust the pH of the reaction solution to 3.8 , and reacted for 3.5 hours at a temperature of 51°C to obtain a lignin-based adhesive prepared by enzymatic modification; alkali lignin was extracted from papermaking waste liquid. The compound enzyme is composed of 20% lignin peroxidase, 20% manganese peroxidase and 60% laccase, and the percentages are mass fractions.

[0038] The application of the aforementioned enzyme-modified lignin-based adhesive comprises the following steps:

[0039] (1) Evenly coating the enzymatically modified lignin-based adhesive on the surface of the veneer to form a plywood slab;

[0040] (2) hot pressing treatment;

[0041] (3) cold pressing treatment.

[0042] In step (1), the amount of glue applied to the enzymatically modified lignin-based adhesive is 0.06g / cm 2 ; Gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com