A kind of aluminum modified acidic silica sol and its preparation method and application

A technology for modification of acidic silica sol and aluminum, which is applied in the field of silicon materials, can solve the problems of insignificant improvement of the purity of acidic silica sol and limited degree of improvement, and achieve increased specific surface area, enhanced functional performance, and improved modification degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

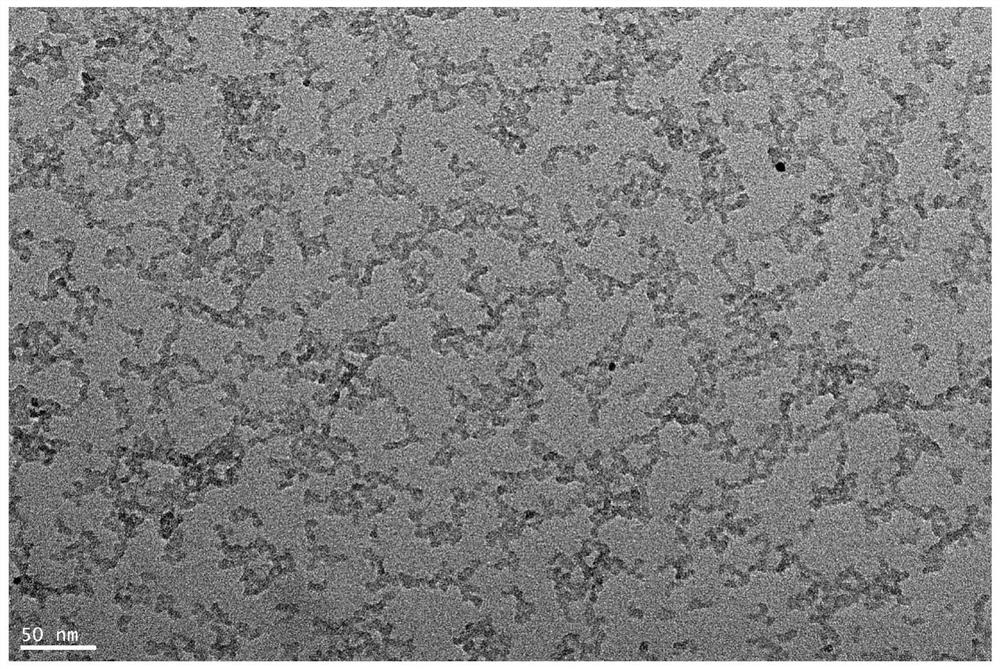

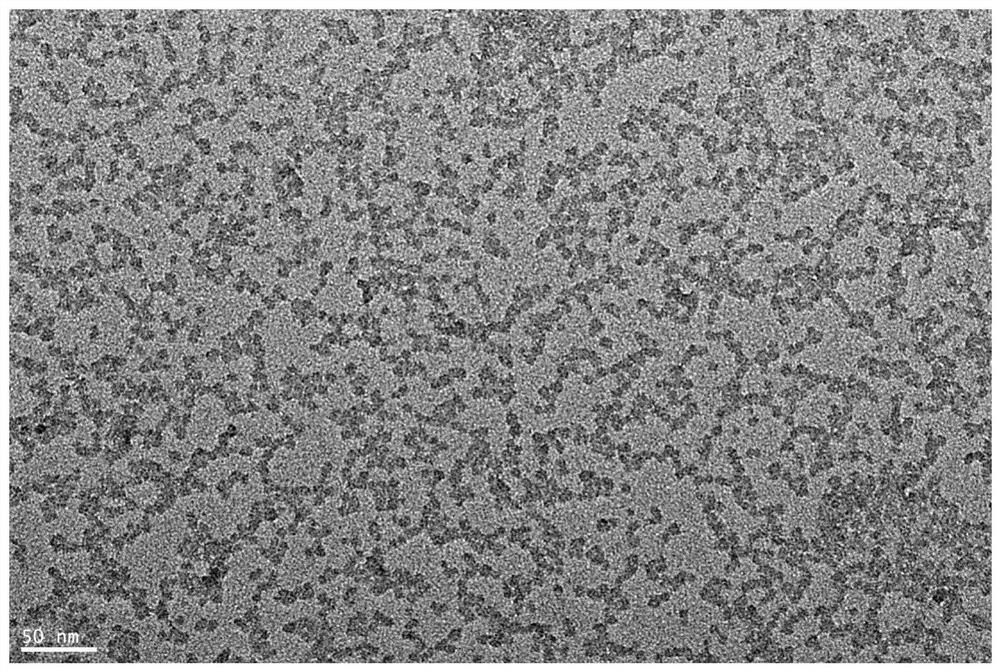

Image

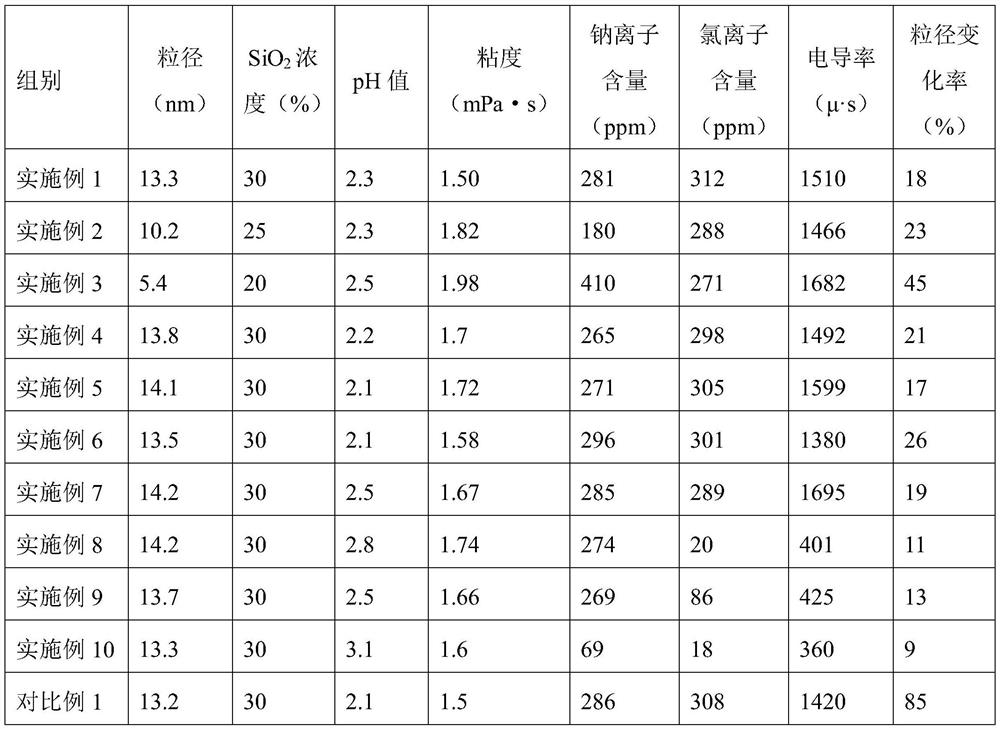

Examples

Embodiment 1

[0052] This embodiment provides an aluminum-modified acidic silica sol, the preparation method of which is:

[0053] (1) dissolving aluminum sulfate in water to make a mass fraction of 5% aluminum sulfate aqueous solution;

[0054] (2) Add the aqueous aluminum sulfate solution obtained in step (1) dropwise at a rate of 50 mL / min into the freshly prepared 3Be active silicic acid solution (obtained by exchanging water glass with a strong-acid cationic resin activated by sulfuric acid), so that the aluminum The salt is dispersed in a silicic acid solution, and a silicic acid solution having a molar ratio of aluminum atoms to silicon atoms of 0.004:1 is prepared;

[0055] (3) Add the aluminum-containing silicic acid solution and the alkaline stabilizer (4% aqueous sodium hydroxide solution) obtained in step (2) dropwise into the alkaline bottom solution (sodium hydroxide solution at pH=12) (containing The volume ratio of the aluminosilicate solution, the alkaline stabilizer, and ...

Embodiment 2

[0059] This embodiment provides an aluminum-modified acidic silica sol, the preparation method of which is:

[0060] (1) dissolving aluminum nitrate in water to make massfraction is 3% aluminum nitrate aqueous solution;

[0061] (2) Add the aluminum nitrate aqueous solution obtained in step (1) dropwise into the freshly prepared 2Be active silicic acid solution (obtained by exchanging water glass with a strong-acid cationic resin activated by sulfuric acid) at a rate of 40mL / min, so that the aluminum The salt is dispersed in a silicic acid solution, and a silicic acid solution having a molar ratio of aluminum atoms to silicon atoms of 0.002:1 is prepared;

[0062] (3) Add the aluminum-containing silicic acid solution and the alkaline stabilizer (2% aqueous sodium hydroxide solution) obtained in step (2) dropwise into the alkaline bottom solution (sodium hydroxide solution at pH=9) (containing The volume ratio of the aluminosilicate solution, the alkaline stabilizer and the al...

Embodiment 3

[0066] This embodiment provides an aluminum-modified acidic silica sol, the preparation method of which is:

[0067] (1) dissolving alum in water to make massfraction is 7% alum aqueous solution;

[0068] (2) Add the alum aqueous solution obtained in step (1) dropwise into the freshly prepared 4.5Be active silicic acid solution (obtained by exchanging water glass with a strong acid cationic resin activated by sulfuric acid) at a rate of 60mL / min to make aluminum The salt is dispersed in a silicic acid solution, and a silicic acid solution having a molar ratio of aluminum atoms to silicon atoms of 0.006:1 is prepared;

[0069] (3) Add the aluminum-containing silicic acid solution and alkaline stabilizer (6% aqueous sodium hydroxide solution) obtained in step (2) dropwise into the alkaline bottom solution (sodium hydroxide solution at pH=14) (containing The volume ratio of the aluminosilicate solution, the alkaline stabilizer and the alkaline base solution is 10:0.3:5), the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com