Process for treating oil by alkali washing

A technology for oil and alkali washing, which is used in the removal of salt or metal ions, and the field of petroleum acid in oil products. It can solve the problems of easy emulsification, long residence time, and low deacidification efficiency. , the effect of high deacidification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

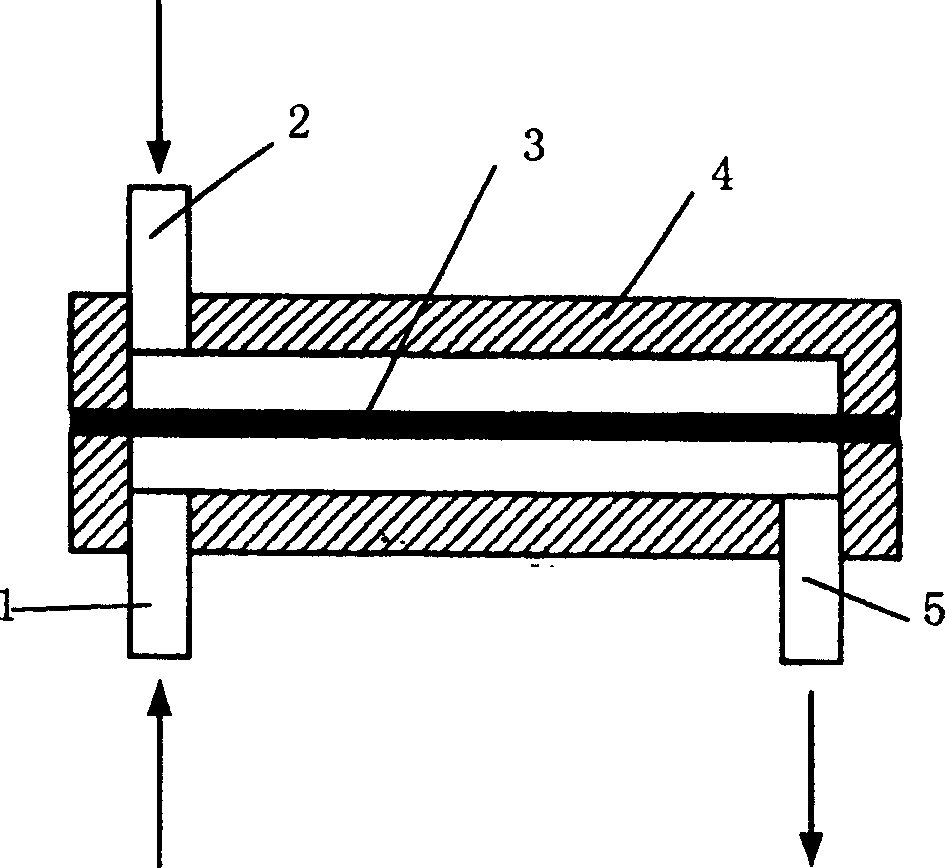

Image

Examples

Embodiment 1

[0013] Use a stainless steel filter membrane with a pore size of 20 μm as the dispersion medium, with an acid value of 1.84 mgKOH.g -1 The gasoline is the oil product system to be treated, and the caustic soda alcohol aqueous solution with a concentration of 3mol / L is the lye system, wherein the volume fraction of ethanol is 10%, and the volume flow ratio of the lye and the oil product is 1: 100, and the two phases are mixed The flow velocity along the surface of the dispersion medium is 1m / s, and the reaction time is 0.5s; the complete separation time of the two phases in the phase separator is 2min; the concentration of petroleum acid remaining in gasoline after phase separation is measured to obtain the deacidification rate 95.5%, lye utilization rate is 79%;

Embodiment 2

[0015] Use a stainless steel plate membrane with a pore size of 10 μm as the dispersion medium, with an acid value of 1.84 mgKOH.g -1 The gasoline is the oil product system to be treated, and the aqueous solution of caustic soda alcohol with a concentration of 0.8mol / L is the lye system, wherein the volume fraction of ethanol is 30%, and the volume flow ratio of lye and gasoline is 1: 25, and the two phases are mixed The flow velocity along the surface of the dispersion medium is 0.3m / s, and the reaction time is 1.67s; the complete separation time of the two phases in the phase separator is 2min; the concentration of petroleum acid remaining in gasoline after phase separation is measured to obtain the deacidification rate is 98%, and the lye utilization rate is 76%;

Embodiment 3

[0017] Use a stainless steel plate membrane with a pore size of 2 μm as the dispersion medium, with an acid value of 1.84 mgKOH.g -1 The gasoline is the oil product system to be treated, and the caustic soda alcohol aqueous solution with a concentration of 0.1mol / L is the lye system, wherein the volume fraction of ethanol is 50%, and the volume flow ratio of lye and gasoline is 1: 3, and the two phases are mixed The flow velocity along the surface of the dispersion medium is 2m / s, and the reaction time is 0.25s; the complete separation time of the two phases in the phase separator is 2min; the concentration of petroleum acid remaining in the gasoline after phase separation is measured to obtain the deacidification rate 97%, lye utilization rate is 73%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com