A kind of porous regenerated cellulose derivative and its preparation method and application

A technology of regenerated cellulose and derivatives, applied in chemical instruments and methods, other chemical processes, bulk chemical production, etc., can solve the problems of low modification efficiency, insoluble cellulose, poor effect, etc., to improve adsorption performance , Improve toughness and increase specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the porous regenerated cellulose derivative of the present invention, in parts by weight, comprises the following steps:

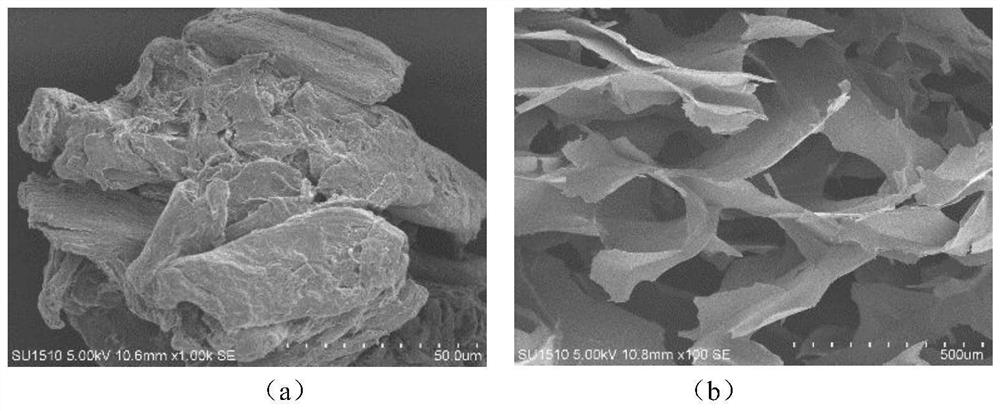

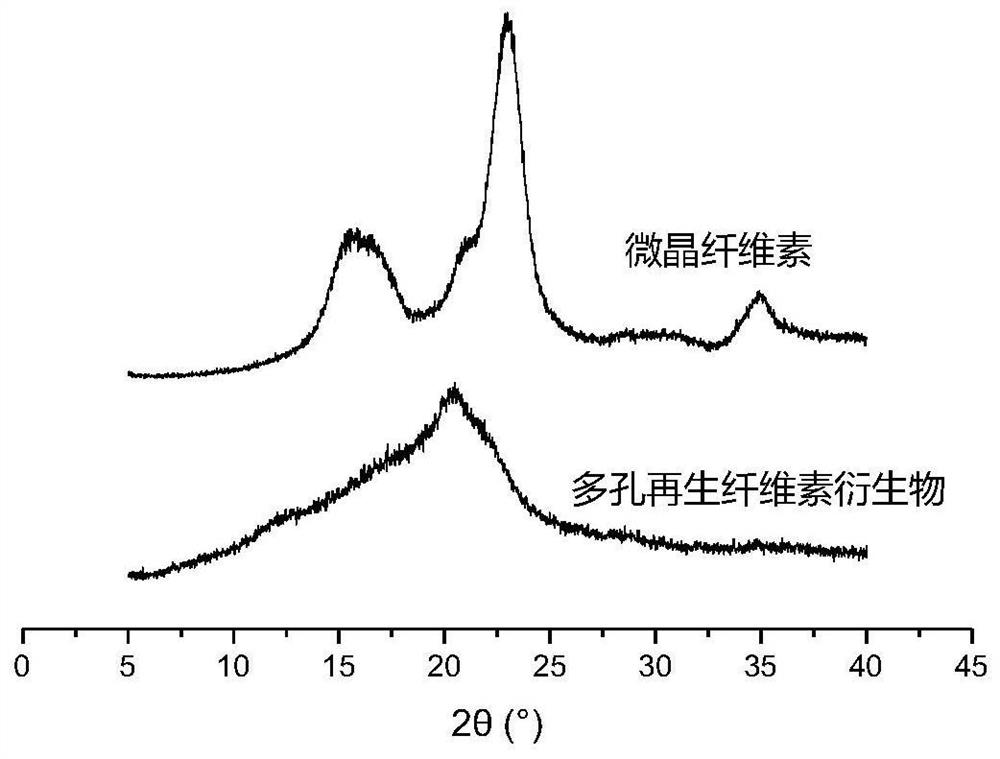

[0029] 40-100 parts of raw materials are dissolved in 400-1000 parts of ionic liquid and 80-150 parts of solvent, and stirred at 25-100° C. until the raw materials are dissolved. Then add 30-70 parts of epoxy component and 0.5-2.0 parts of initiator, after 0.5-2 hours of reaction, add 20-50 parts of amino acid and 1.0-5.0 parts of amino silicone oil, and continue to react for 0.5-3 hours. The reactants are poured into a mold or casted on a support material, and finally placed in a gel bath, the cellulose derivatives are slowly precipitated and regenerated, and a porous adsorbent is obtained after freeze-drying.

[0030] In the preparation method of the above-mentioned porous regenerated cellulose derivative, the raw material is one of microcrystalline cellulose, absorbent cotton, softwood or hardwood pulp; the ionic liquid ...

Embodiment 1

[0047] (1) Add 40 parts of microcrystalline cellulose, 800 parts of 1-butyl-3-methylimidazolium chloride ionic liquid and 80 parts of dimethyl sulfoxide in a three-necked flask equipped with mechanical stirring, nitrogen, condensation and reflux , heating and mechanical stirring until the microcrystalline cellulose is completely dissolved. After the system was cooled to room temperature, 1.0 part of potassium persulfate was transferred into a three-necked flask, 105 parts of glycidyl methacrylate were added, and the reaction was carried out at room temperature for 0.5 hour. After that, nitrogen flow was stopped, and 108 parts of L-lysine was added to continue the reaction for 3 hours. The reactant is poured into the mold, and then the mold is placed in the gel bath water, the cellulose derivative is slowly precipitated and regenerated, and the porous adsorbent is obtained after freeze-drying.

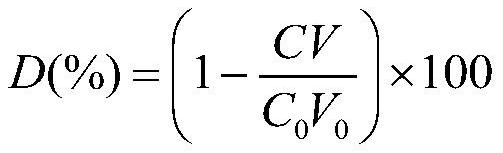

[0048] (2) At room temperature, prepare 100 mL of 150 mg / L reactive brilliant red ...

Embodiment 2

[0053] (1) Add 40 parts of microcrystalline cellulose, 800 parts of 1-butyl-3-methylimidazolium chloride ionic liquid and 80 parts of dimethyl sulfoxide in a three-necked flask equipped with mechanical stirring, nitrogen, condensation and reflux , heating and mechanical stirring until the microcrystalline cellulose is completely dissolved. After the system was cooled to room temperature, 1.0 part of potassium persulfate was transferred into a three-necked flask, 105 parts of glycidyl methacrylate were added, and the reaction was carried out at room temperature for 0.5 hour. After that, nitrogen flow was stopped, and 108 parts of L-lysine and 1.0 part of amino silicone oil were added to continue the reaction for 3 hours. The reactant is poured into the mold, and then the mold is placed in the gel bath water, the cellulose derivative is slowly precipitated and regenerated, and the porous adsorbent is obtained after freeze-drying.

[0054] (2) At room temperature, prepare 100 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com