Preparation method of thermoplastic resin/fiber composite material

A fiber composite material and thermoplastic resin technology, which is applied in the field of polymer composite materials to achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 linear low density polyethylene / UHMWPE fiber blend

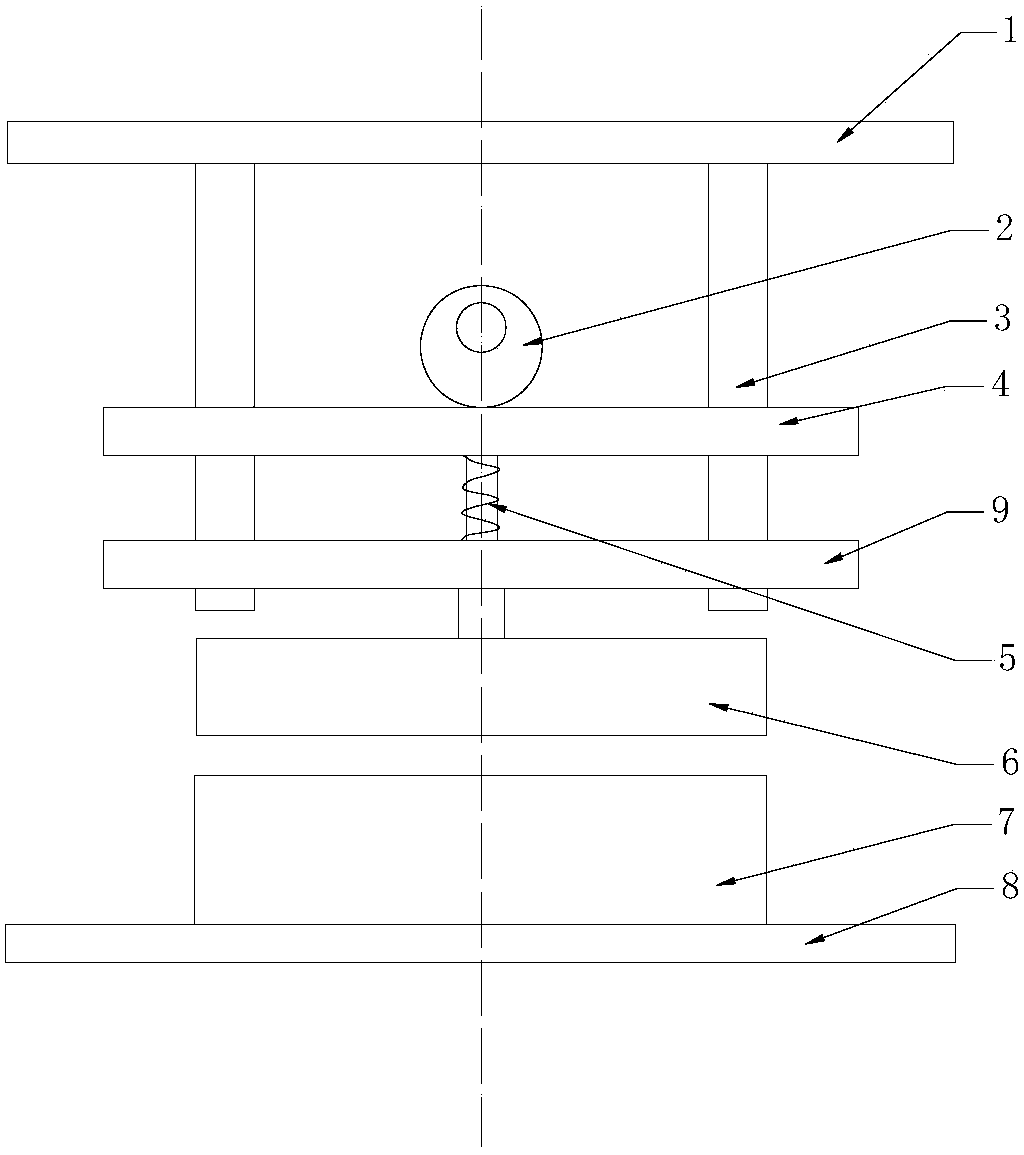

[0027] The LLDPE / UHMWPE fibers (80:20) were blended on a torque rheometer at a temperature of 135° C., the mixing shear rate of the torque rheometer was 50 rpm, and mixed for 10 minutes to obtain a blended composite material. The above composite material was pre-compressed for 5 minutes and then pressed for 5 minutes under the conditions of 140° C. and 10 MPa with a vacuum laminator to obtain a disc with a diameter of 55 mm and a thickness of 1.05 mm. Use the discs prepared above at 125°C (at this temperature, the material is in a highly elastic state) and at 150°C (at this temperature, the material is in a molten state) figure 1 Vibration is applied by the automatic vibration device shown, the vibration time is 1 min, and the vibration frequency is 100 rad / min, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com