Modified polyvinyl alcohol and preparation method thereof

A polyvinyl alcohol, modification technology, applied in the field of modified polyvinyl alcohol and its preparation, can solve the problems of difficult industrialization, lower melting temperature, escape modification system, etc., and achieve easy industrialization and high thermal stability , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

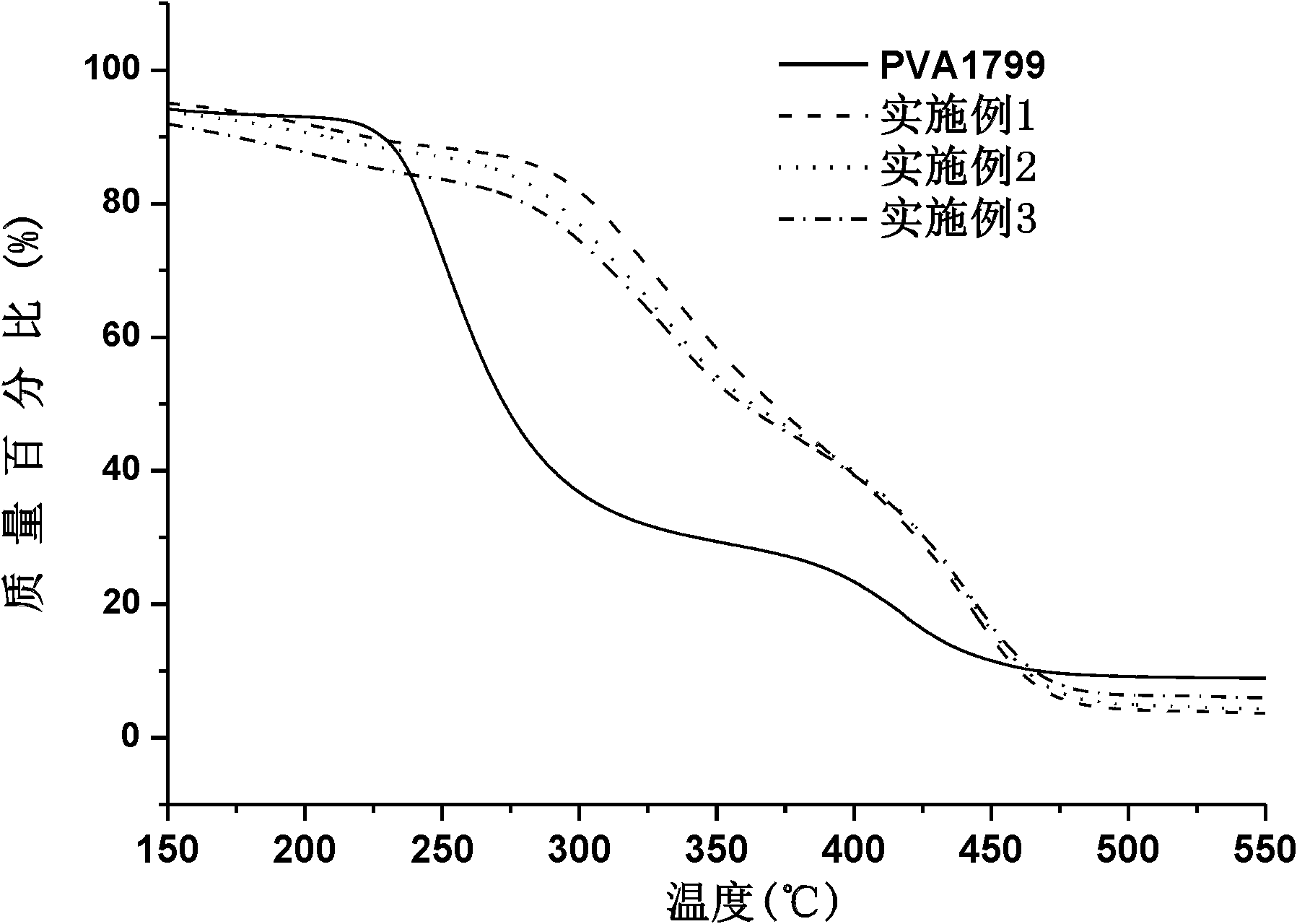

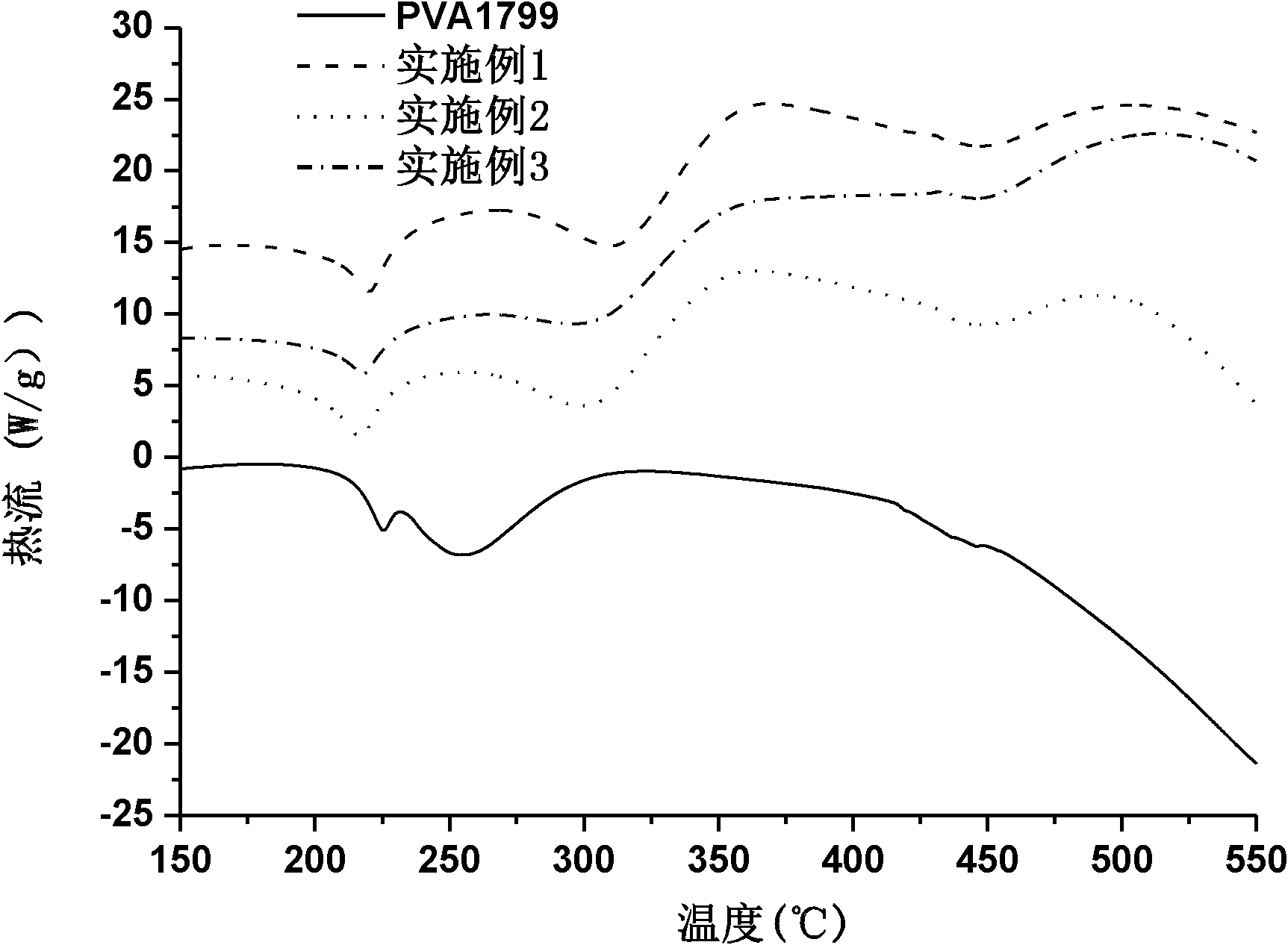

Embodiment 1

[0038] Dissolve 100 grams of PVA1799 in 900 grams of dimethyl sulfoxide, the dissolution temperature is 90 ° C, and the time is 4 hours, called solution A, cooled to room temperature for later use; in addition, 10 grams of hyperbranched In methyl sulfoxide, the dissolution temperature is 80°C, and the time is 2 hours. It is called solution B, and it is cooled to room temperature for later use; then take 100 grams of solution A and 20 grams of solution B, stir and mix evenly, and the PVA1799 in the final mixed solution The mass concentration is 8.33%, the hyperbranched polymer is 10% by weight of polyvinyl alcohol, and dried in an oven at 100° C. for 12 hours to obtain film-shaped modified polyvinyl alcohol, which can be crushed or used directly according to actual processing.

Embodiment 2

[0040] Get 100 grams of solution A and 1 gram of solution B in Example 1, stir and mix evenly, the mass concentration of PVA1799 in the mixed solution is 9.90%, and the hyperbranched polymer is 0.5% by weight of polyvinyl alcohol, in an oven at 100 ° C After drying for 12 hours, the film-shaped modified polyvinyl alcohol can be obtained, which can be successfully prepared by crushing or directly using according to actual processing.

Embodiment 3

[0042] Get 100 grams of solution A and 40 grams of solution B in Example 1, stir and mix evenly, the mass concentration of PVA1799 in the mixed solution is 7.14%, and the hyperbranched polymer is 20% of the weight of polyvinyl alcohol. Dry for 12 hours in medium to obtain film-shaped modified polyvinyl alcohol, which can be crushed or used directly according to actual processing

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com