Forming method of SiCp/Al composite material

A composite material and forming method technology, applied in the field of powder metallurgy materials, can solve the problems of low production efficiency, high process cost, high labor cost, etc., and achieve the effects of short hot pressing time, improved feasibility and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Step 1) SiC selects abrasive-grade green silicon carbide powder with a particle diameter of 63 μm;

[0052] Al selects industrial pure aluminum powder, and Al50Mg powder is a commercially available alloy powder with a particle size of 100 μm. These two powders are prepared into a mixed powder whose nominal composition is Al10Mg;

[0053] Then SiC particles and Al10Mg mixed powder are uniformly mixed in a volume ratio of 60%: 40%;

[0054] Step 2) Put the uniformly mixed SiC / Al powder in step 1) into a steel cold press mold, and press and form it into a SiC / Al blank under a press pressure of 100 MPa;

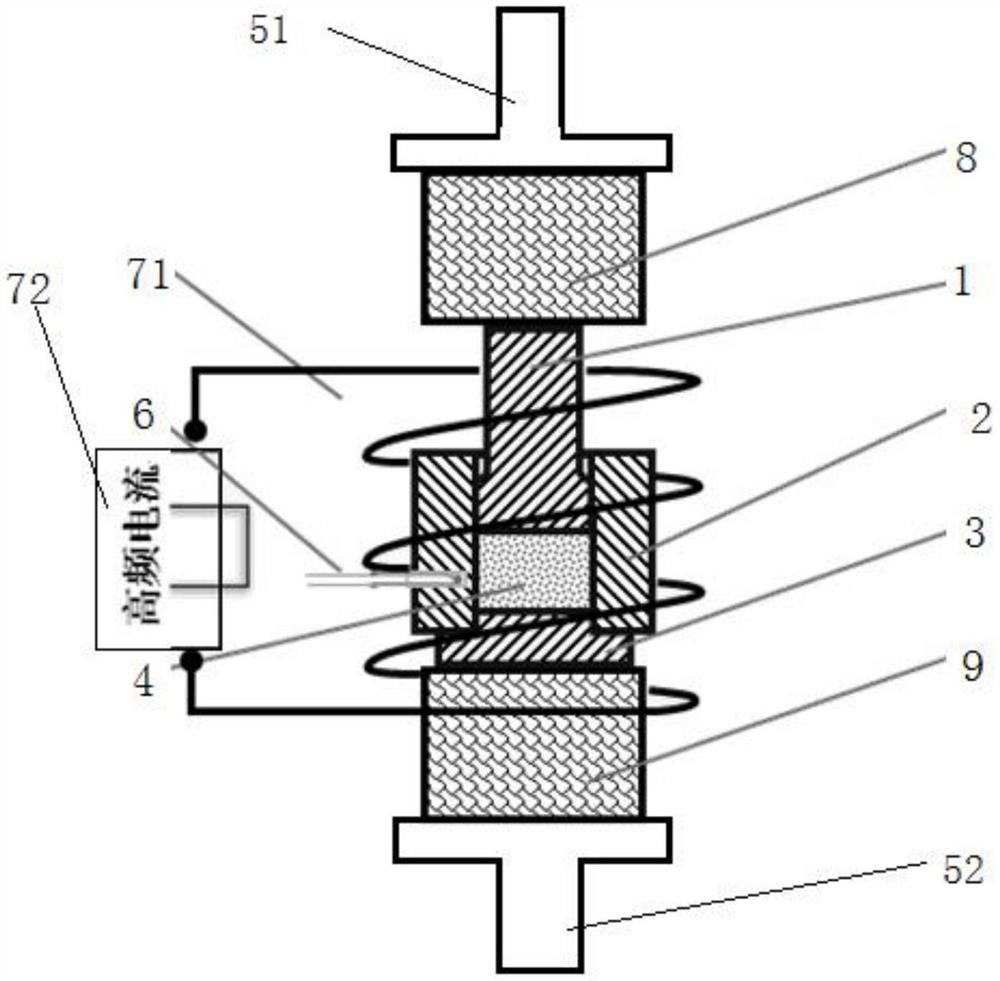

[0055] Step 3) Put the cold-pressed SiC / Al formed in step 2) into a hot-pressing mold made of graphite under atmospheric pressure conditions, and perform hot-pressing sintering by using rapid heating and hot-pressing technology. Among them, the sintering process of the rapid heating and hot pressing technology is: the heating temperature is 600°C, the applied pressure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com