Combined double-sided adhesive tape structure and method

A double-sided tape, combined technology, used in bonding methods, adhesives, film/sheet-like adhesives, etc. Good to make up for problems such as concave and convex surface gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in conjunction with accompanying drawing;

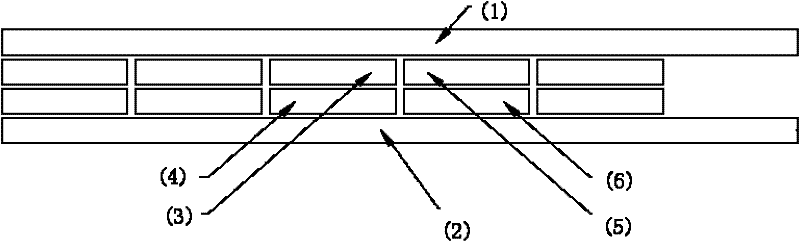

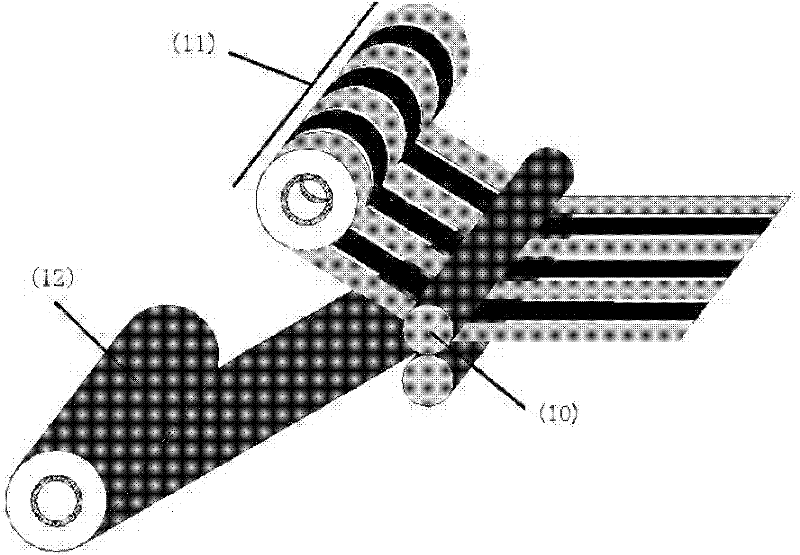

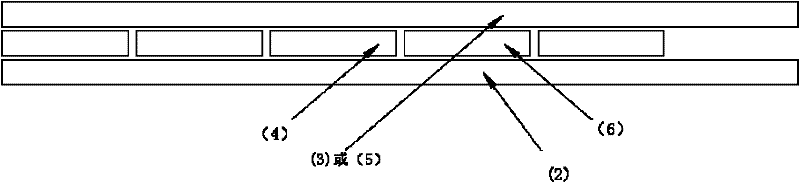

[0041] like figure 2 As shown, the hot-pressed double-sided tape and the pressure-sensitive double-sided tape are fixed on the single-sided tape (or release paper) through the roller of the laminating machine according to a certain combination method by using a multi-functional laminating machine, and then punched out by die-cutting Process specific shapes and positioning holes, etc., and then cooperate with pressing, pre-attaching or cold, hot pressing and other jigs to accurately position and paste the tape on the product to be assembled. During the hot pressing process, the pressure-sensitive double-sided sticky at room temperature The tape can position the product very well, thereby avoiding movement during the product assembly process, thereby greatly shortening the time of thermal bonding, and making the combined product have a very large structural strength.

[0042] Its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com