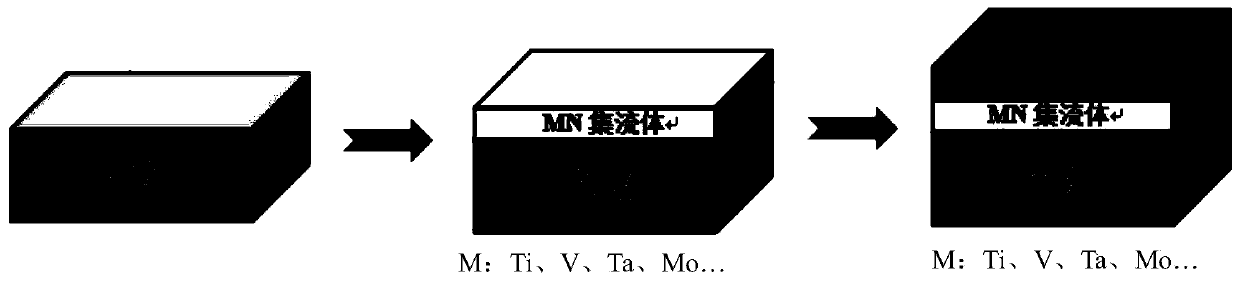

Full-transition metal nitride current collector/electrode supercapacitor and preparation method thereof

A supercapacitor, transition metal technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, hybrid capacitor current collectors, etc., can solve the problem of frequency response (poor rate characteristics, etc.) The effect of many, the process is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

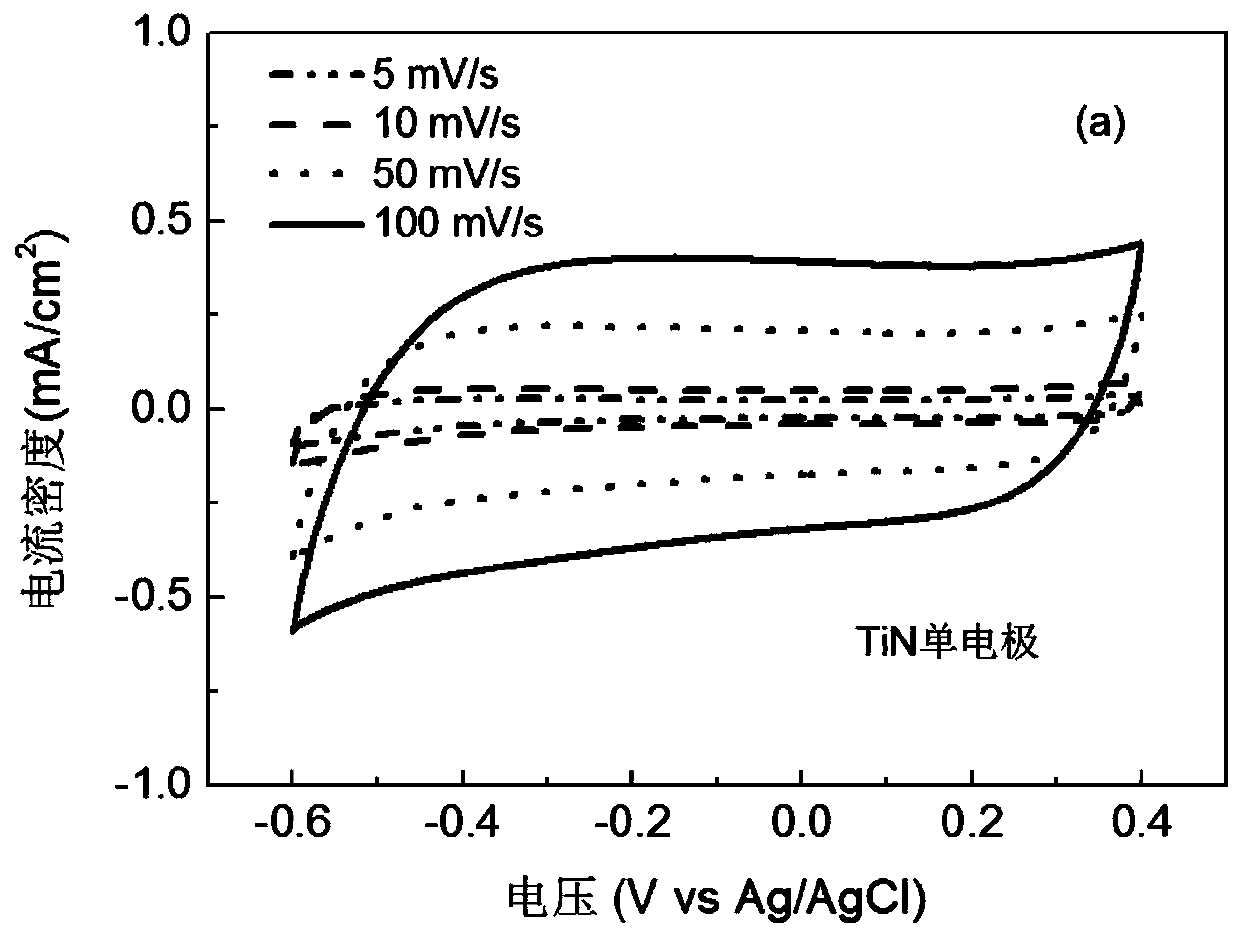

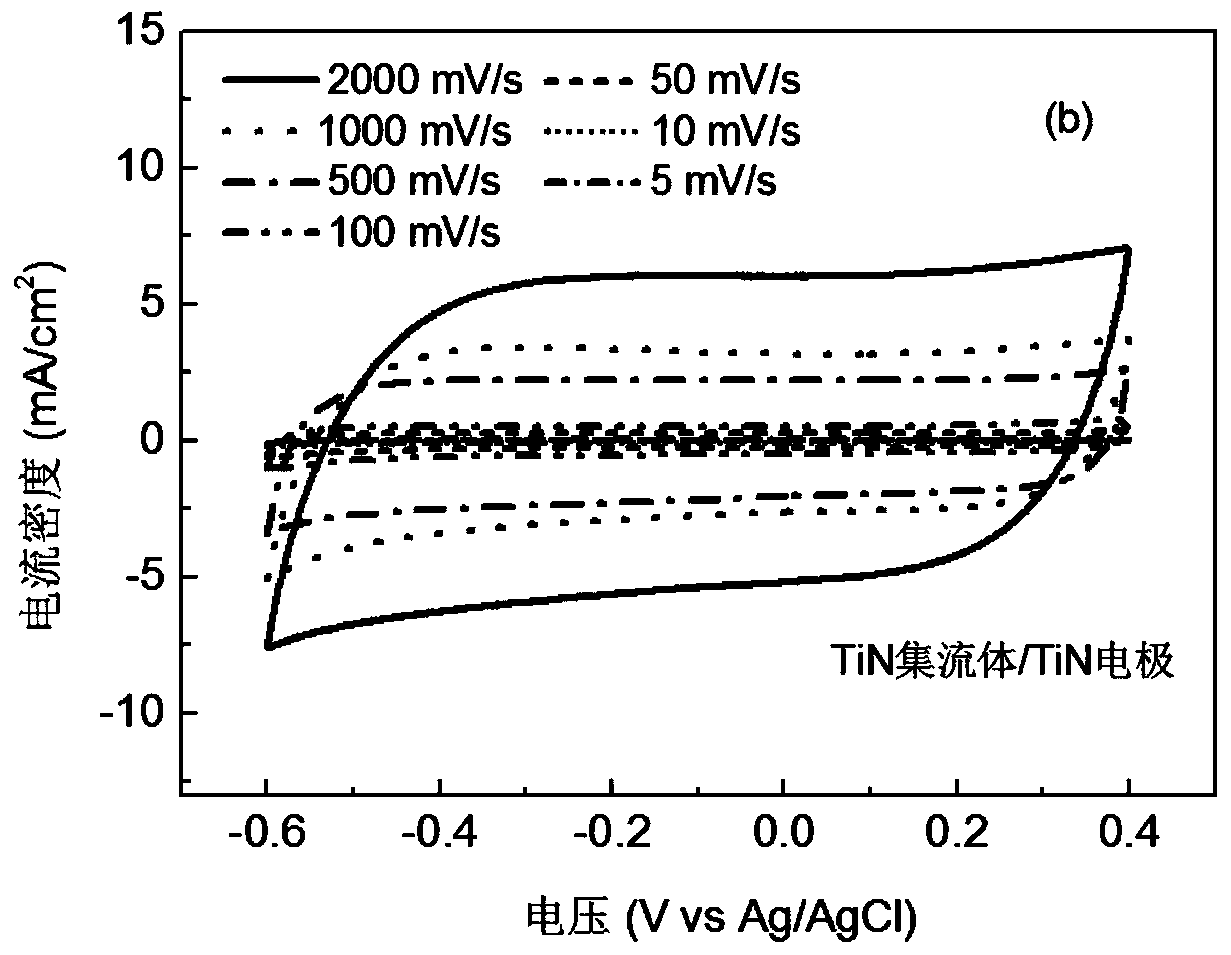

[0031] In this embodiment, a single crystal silicon substrate is selected as the substrate, and the semiconductor industry standard RCA cleaning process is used for cleaning. DC reactive magnetron sputtering is adopted, the target material is titanium metal, the base distance of the target is 20cm, Ar:N 2 =10:1sccm, sputtering power: 100W, substrate temperature: 400°C, working pressure: 0.2Pa, substrate bias voltage: -50V, sputtering time: 10min, first deposit a layer with a thickness of 38nm, and a resistivity of 108μΩ·cm , the surface is smooth and dense TiN thin film is used as the current collector material, and then the distance between the target and the base is 20cm, Ar:N 2 =10:1sccm, sputtering power: 100W, substrate temperature: 400°C, working pressure: 0.4Pa, sputtering time: grow a layer of thickness 240nm under the conditions of 30min, resistivity 2800μΩ·cm, loose and porous TiN film as electrode material. Using a three-electrode test system, the working electrod...

Embodiment example 2

[0033] In this embodiment, a single crystal silicon substrate is selected as the substrate, and the semiconductor industry standard RCA cleaning process is used for cleaning. DC reactive magnetron sputtering is adopted, the target material is titanium metal, the base distance of the target is 40cm, Ar:N 2 =20:1sccm, sputtering power: 200W, substrate temperature: 300°C, working pressure: 0.2Pa, substrate bias: -50V, sputtering time: 10min, deposit a layer with a thickness of 30nm first, and a resistivity of 128μΩ·cm , the surface is smooth and dense TiN thin film is used as the current collector material, and then the distance between the target and the base is 20cm, Ar:N 2 =10:1sccm, sputtering power: 100W, substrate temperature: 400°C, working pressure: 0.4Pa, sputtering time: grow a layer of thickness 240nm under the conditions of 30min, resistivity 2800μΩ·cm, loose and porous TiN film as electrode material. Using a three-electrode test system, the working electrode is TiN...

Embodiment example 3

[0035] In this embodiment, a single crystal silicon substrate is selected as the substrate, and the semiconductor industry standard RCA cleaning process is used for cleaning. Using radio frequency reactive magnetron sputtering, the target material is vanadium metal, the target base distance is 50cm, Ar:N 2 =20:1sccm, sputtering power: 150W, substrate temperature: 200°C, working pressure: 0.6Pa, substrate bias: -150V, sputtering time: 20min, first deposit a layer with a thickness of 79nm and a resistivity of 188μΩ·cm , the surface is smooth and dense VN thin film as the current collector material, and then the distance between the target and the base is 50cm, Ar:N 2 =20:1sccm, sputtering power: 150W, substrate temperature: 200°C, working pressure: 0.6Pa, sputtering time: grow a layer of thickness 300nm under the condition of 40min, resistivity 3600μΩ·cm, loose and porous VN film as electrode material. Using a three-electrode test system, the working electrode is VN, the count...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com