C/ZrC-SiC ultrahigh-temperature ceramic-based composite material and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, applied in the field of C/ZrC-SiC ultra-high temperature ceramic matrix composite materials and its preparation, can solve problems such as high risk of delamination, achieve wide application prospects, excellent anti-oxidation and ablation resistance , The effect of strong process applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a first aspect, the present invention provides a method for preparing a C / ZrC-SiC ultra-high temperature ceramic matrix composite material, the method comprising the following steps:

[0028] (1) Provide n parts of carbon cloth and n-1 parts of ZrC (zirconium carbide) powder, and lay a layer of ZrC powder layer on the carbon cloth layer after each layer of carbon cloth layer. A powdered carbon fiber prefabricated body formed by alternating layers of cloth layers and ZrC powder layers; ZrC powder layer, that is, nano-ZrC ultra-high temperature ceramic powder is added in the layering process of carbon cloth to obtain a powdered carbon fiber preform added with ZrC powder; specifically, in the present invention, a powdered carbon fiber preform is prepared The method is: the carbon cloth layer and the ZrC (zirconium carbide) powder layer are laid alternately in the XY direction of the powdered carbon fiber prefabricated body, and the carbon cloth layer is used between the...

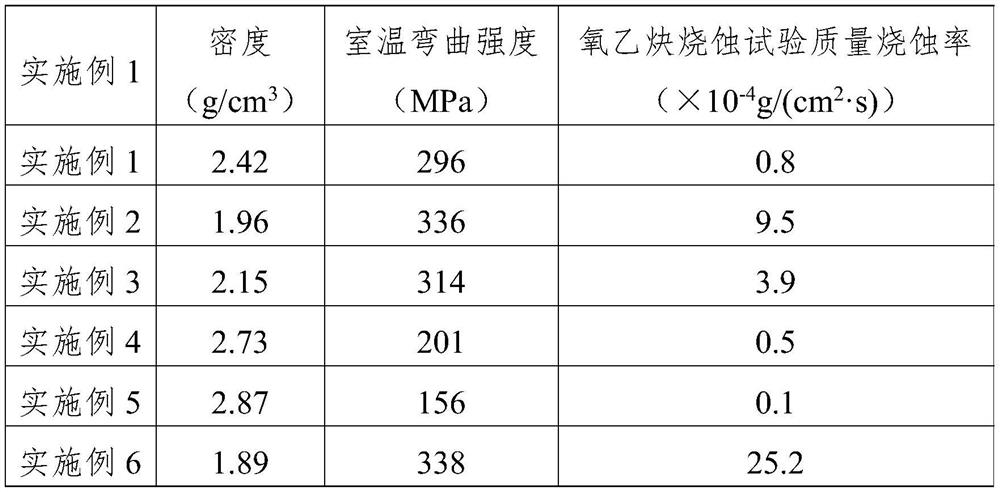

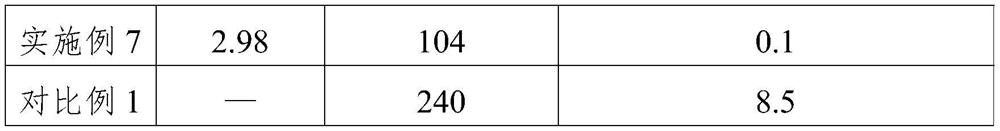

Embodiment 1

[0048] ① Preparation of powdered carbon fiber prefabricated body with carbon cloth laminated suture structure, the preparation method is to alternately superimpose layers of one layer of carbon cloth + one layer of ZrC powder, and then form a powdered carbon fiber prefabricated body with a sutured structure by sewing; , the mass ratio of the fiber contained in the carbon cloth in the prefabricated body to the ZrC powder in the prefabricated body is 1:1, and the density of the powdered carbon fiber prefabricated body is 1.10g / cm 3 .

[0049] ②Preparing a C interface layer on the surface of the powdered carbon fiber prefabricated body by chemical vapor deposition process to obtain a low-density C / C composite material, and the density increment of carbon deposition is 0.1g / cm 3 .

[0050] ③ Using the polycarbosilane precursor solution as the impregnation solution, the SiC matrix was densified by the PIP process.

[0051] ④ Densification by 8 cycles of PIP process to obtain C / Zr...

Embodiment 2

[0054] ① Preparation of powdered carbon fiber prefabricated body with carbon cloth laminated suture structure, the preparation method is to alternately superimpose layers of one layer of carbon cloth + one layer of ZrC powder, and then form a powdered carbon fiber prefabricated body with a sutured structure by sewing; , the mass ratio of the fiber contained in the carbon cloth in the prefabricated body to the ZrC powder in the prefabricated body is 1:0.2.

[0055] ②Preparing a C interface layer on the surface of the powdered carbon fiber prefabricated body by chemical vapor deposition process to obtain a low-density C / C composite material, and the density increment of carbon deposition is 0.1g / cm 3 .

[0056] ③ Using the polycarbosilane precursor solution as the impregnation solution, the SiC matrix was densified by the PIP process.

[0057] ④ Densification by 8 cycles of PIP process to obtain C / ZrC-SiC ultra-high temperature ceramic matrix composites.

[0058] The density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com