Vehicle tire with outer tire containing foamed inner tube for small traffic vehicles with a speed of less than 35km per hour, and its preparation mold and preparation method

A technology for vehicles and inner tubes, which is applied to special tires, vehicle parts, tire parts, etc. It can solve the problems of short foaming reaction time, insufficient structure of mold preparation, and difficulty in ensuring the quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

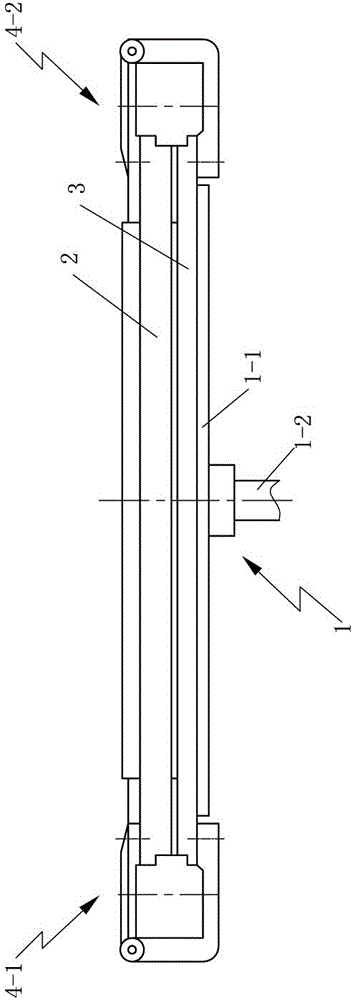

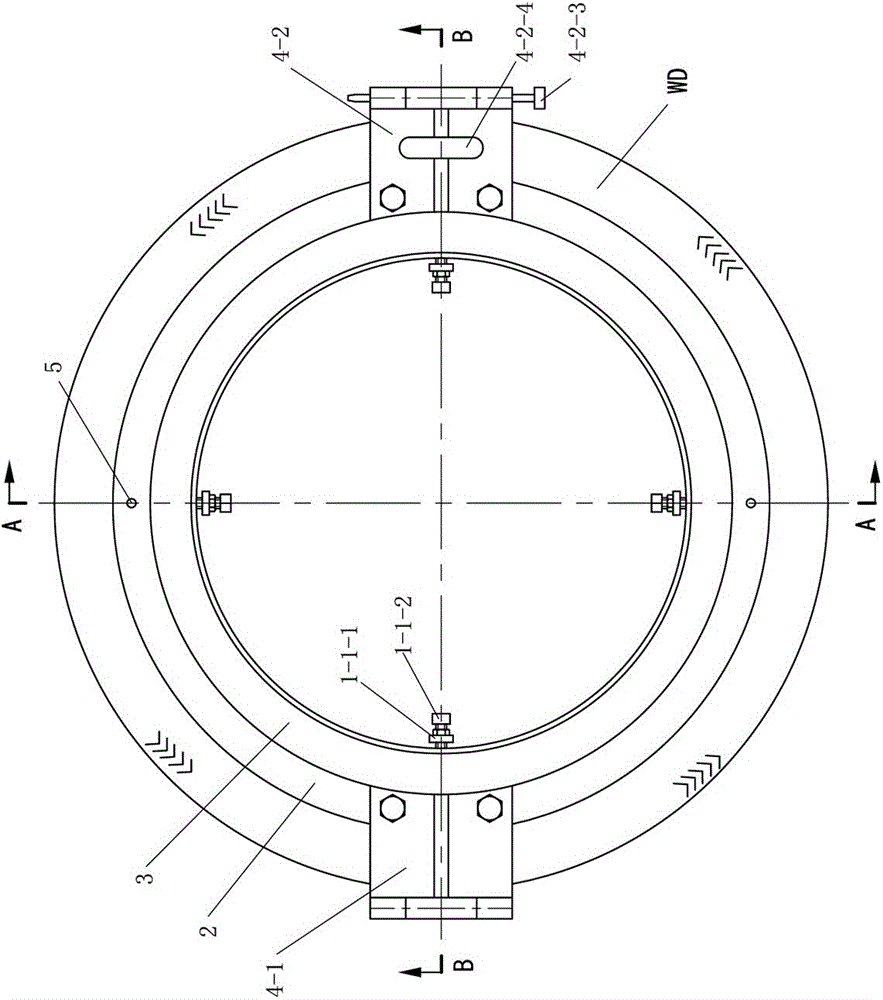

[0052] The present invention will be further described below through the description of specific embodiments in conjunction with the accompanying drawings.

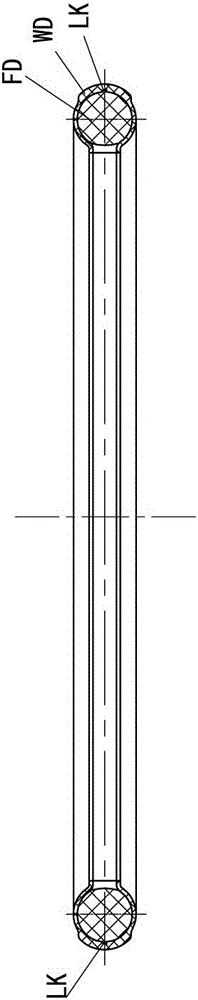

[0053] One of the specific implementation modes, as attached figure 1 shown.

[0054] A vehicle tire containing a foamed inner tube in the outer tire of a small traffic vehicle with a speed of less than 35km per hour, including a vehicle outer tire WD and a foamed inner tube FD, and the foamed inner tube FD is thrown into the vehicle outer tire WD by centrifugal pouring of liquid foaming material The inner cavity of the vehicle tire WD is tightly attached to the inner cavity of the vehicle tire by foaming to form a whole, and its,

[0055] a. The proportion of the total volume of the pores of the foamed inner tube FD is in the range of 30% to 40%;

[0056] b. The pores of the foamed inner tube FD are composed of closed-loop pores that do not communicate with each other and open-loop pores that communicate with each othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com