Method for adjusting bent air grid of parallel bent toughening furnace

An adjustment method and air grille technology, which are applied in the tempering of glass, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of inability to ensure the fit of different curved tempered glasses, difficulty in calculating and adjusting the height of variable arc dragon nuts, and single-sided bending and tempering. Incomplete arc and other problems, to achieve the effect of beautiful appearance, simple adjustment and control, and good quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Adjustment of curved air grille

[0016] 1-1 Making templates: Use high-strength heat-resistant materials to make square plates, draw arcs on the plates with the radius of curved tempered arcs, and cut out the arcs.

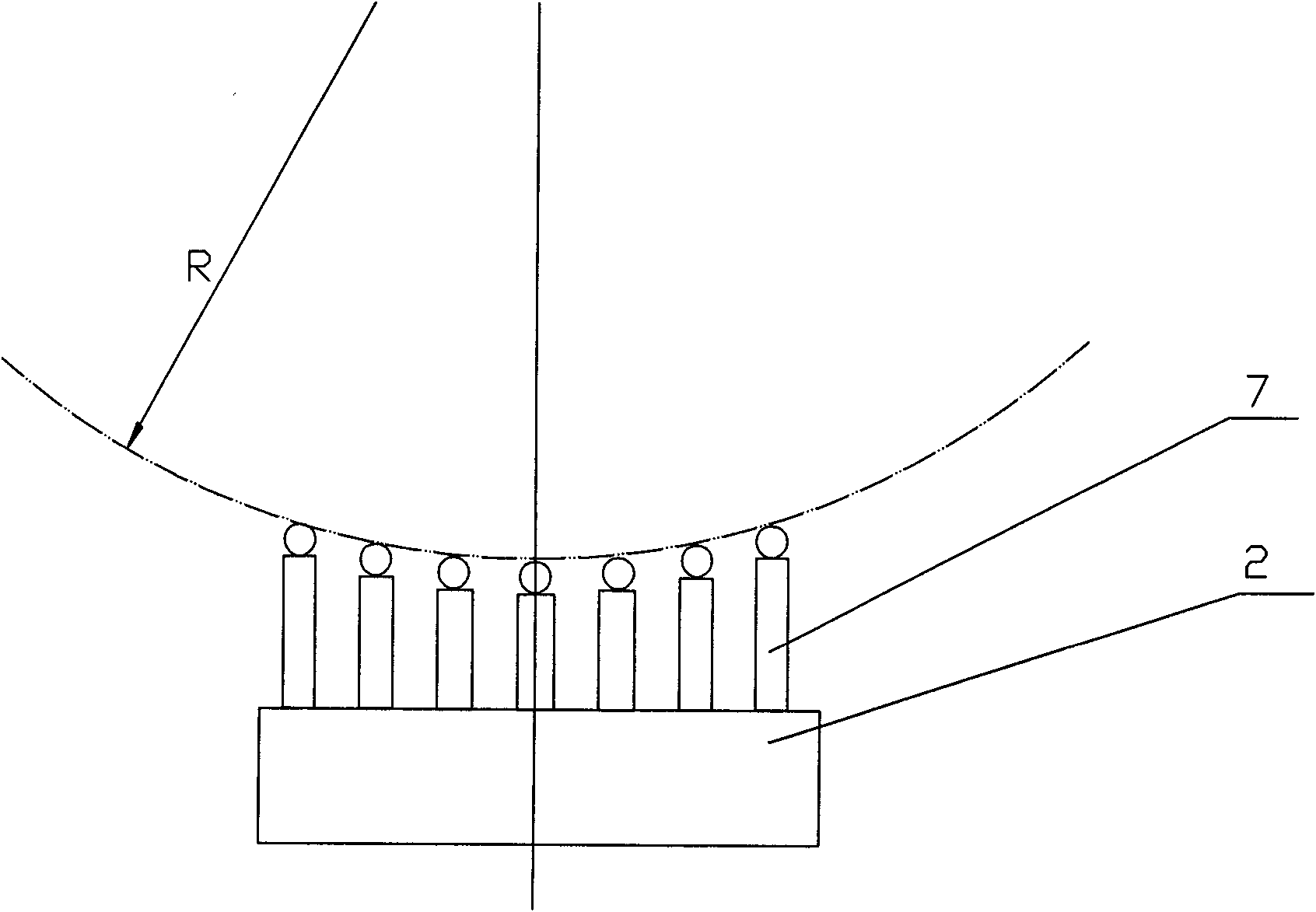

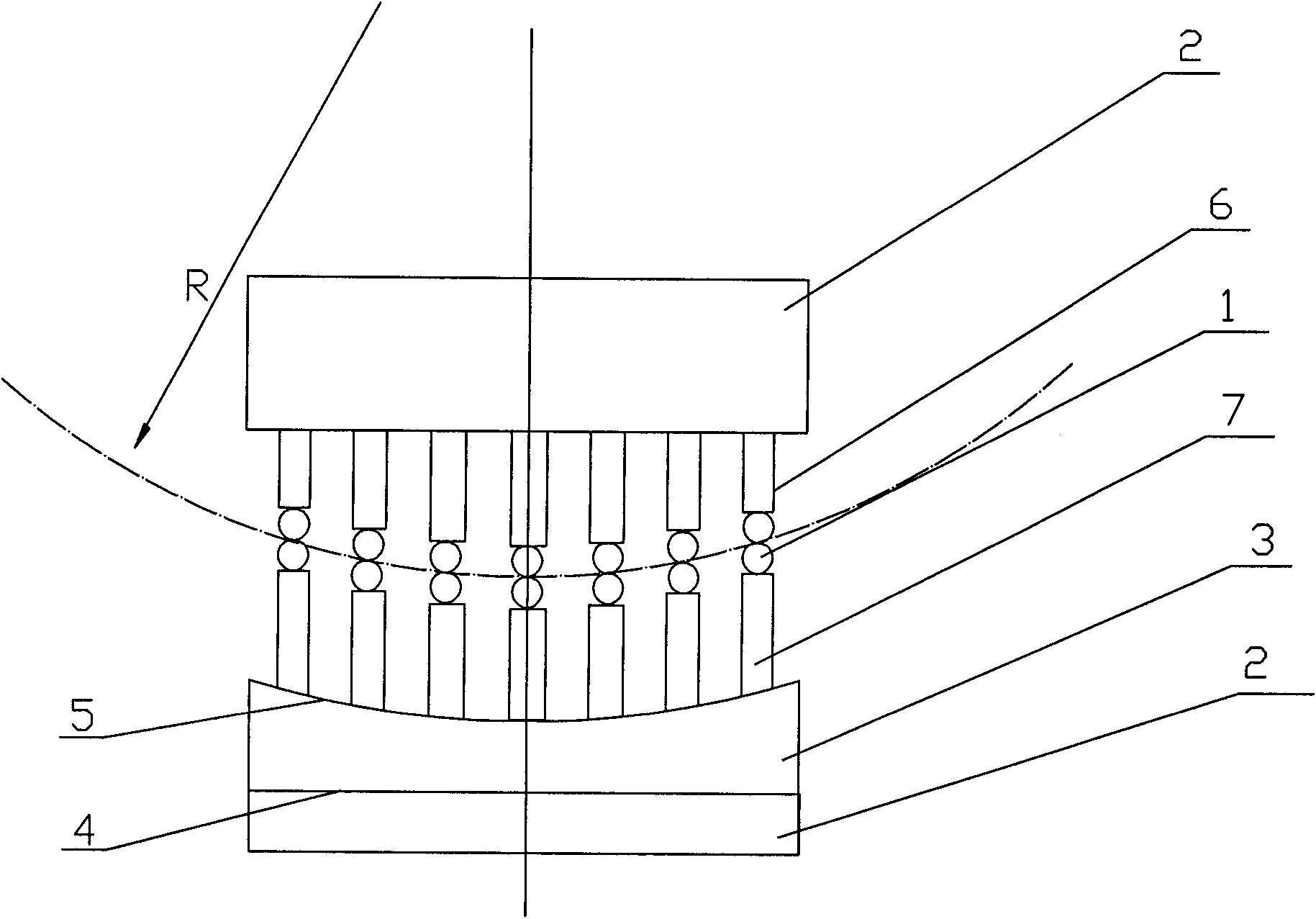

[0017] 1-2 Fixing the formwork: fix the plane 4 side of the formwork on the support plate 2, and the arc surface 5 side upwards.

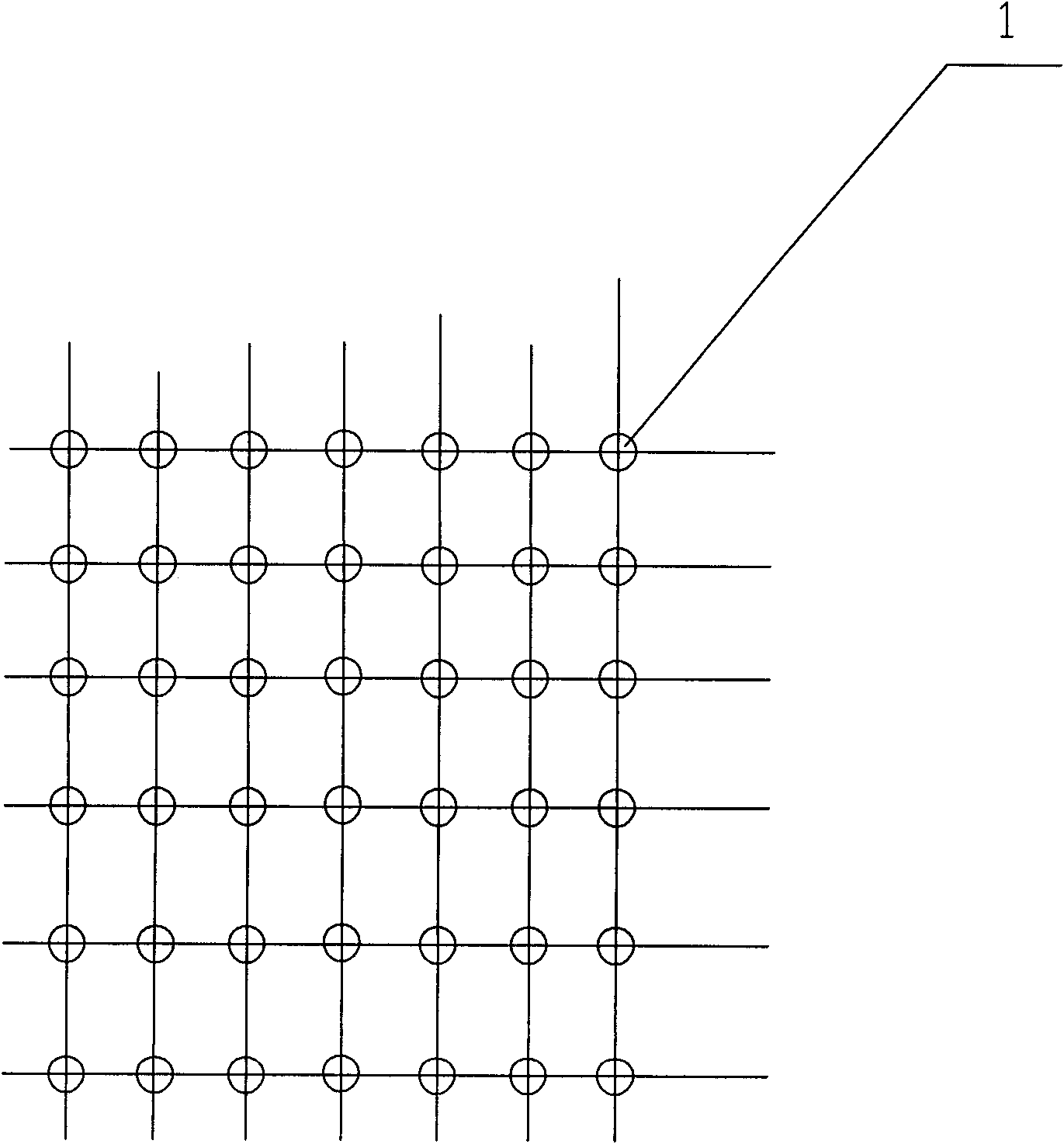

[0018] 1-3 Adjust the lower air grid: fix the dot matrix roller 1 of the lower air grid 7 on the arc surface 5 of the template 3, since the arc surface of the template has the same radius as the curved tempered arc, therefore, the distance between the dot matrix roller 1 and the arc If the height of the surface is adjusted to be consistent, then the dot matrix roller 1 naturally has a curved surface with the same radius as the curved tempered arc.

[0019] 1-4 Adjust the upper air grille: put the upper air grille 6 on the lower air grille 7, loosen the adjustment screws on the air grille, make the dot matrix structu...

Embodiment 2

[0021] Embodiment 2: Production of curved tempered glass

[0022] 1. After the glass is heated in the heating furnace, it is sent into the curved air grid through the roller table, and one side of the glass naturally falls on the curved arc surface of the lower air grid.

[0023] 2. The upper air grille falls, and its curved curved surface is close to the other surface of the glass, which is rapidly formed and cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com