Patents

Literature

91results about How to "Good quality assurance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

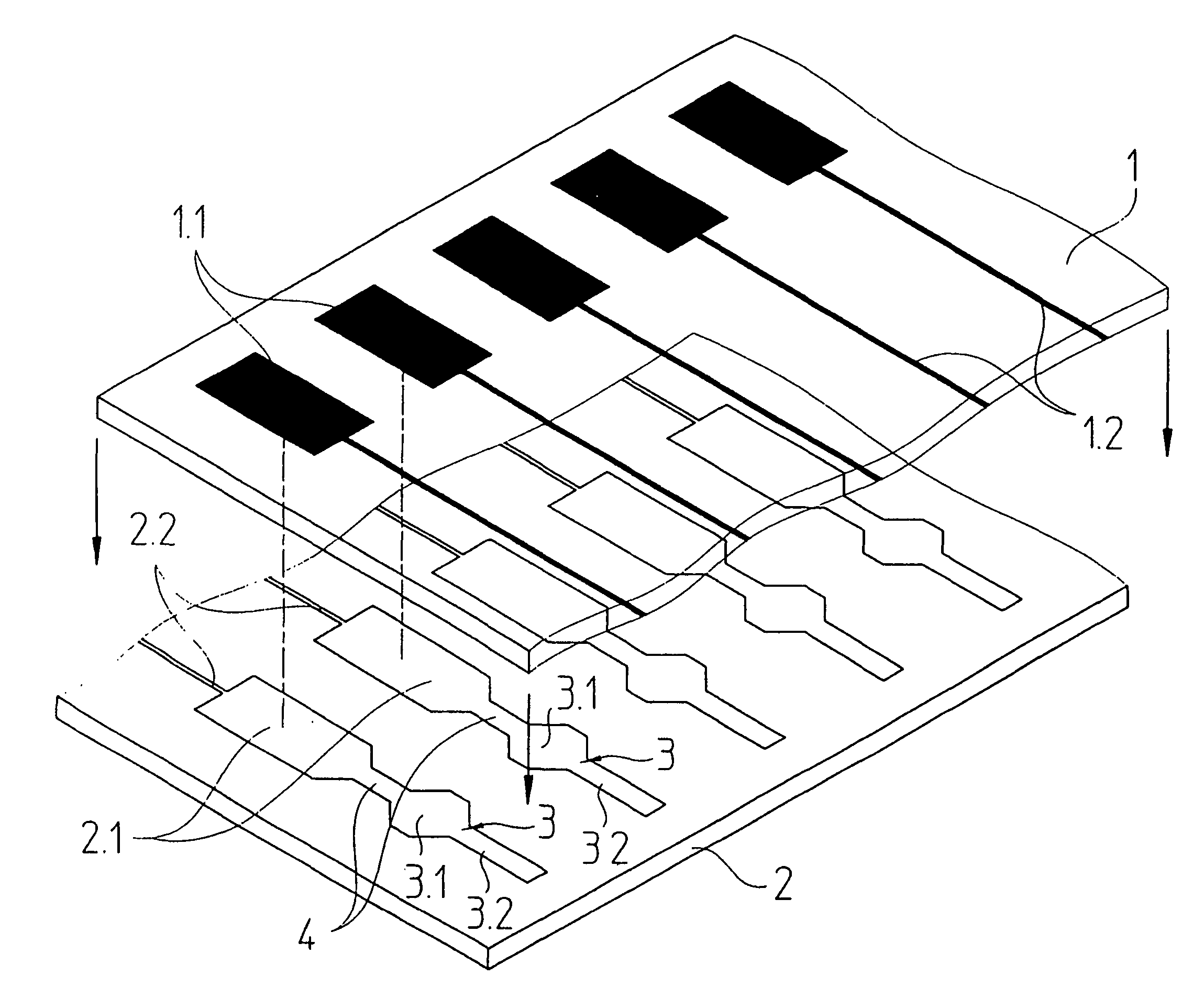

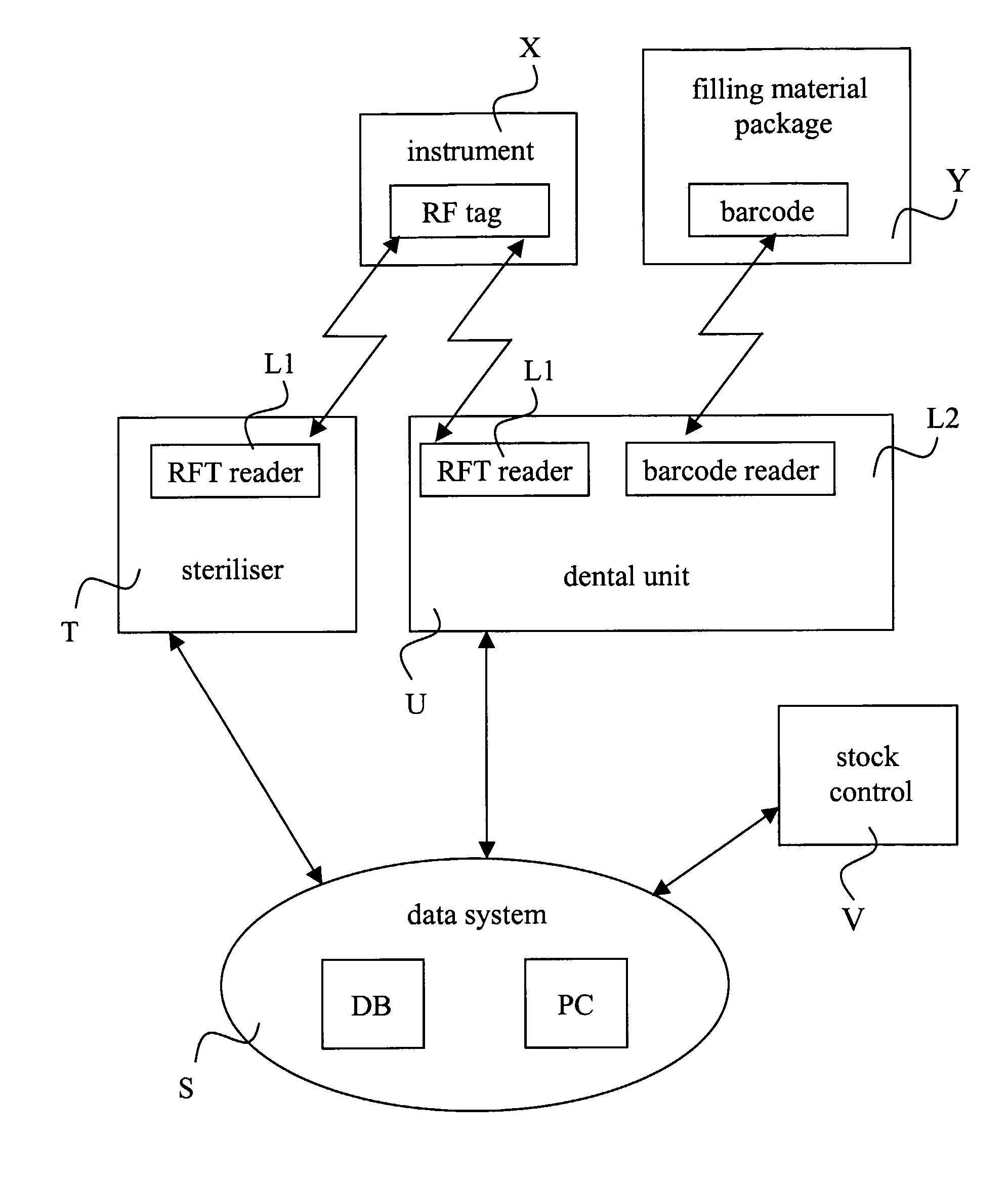

Data Arrangement, Method, Dental-Care-Related Device and Software Product for Dental-Care Quality Assurance

ActiveUS20080120137A1Good quality assuranceEasy to processData processing applicationsSurgeryControl systemFilling materials

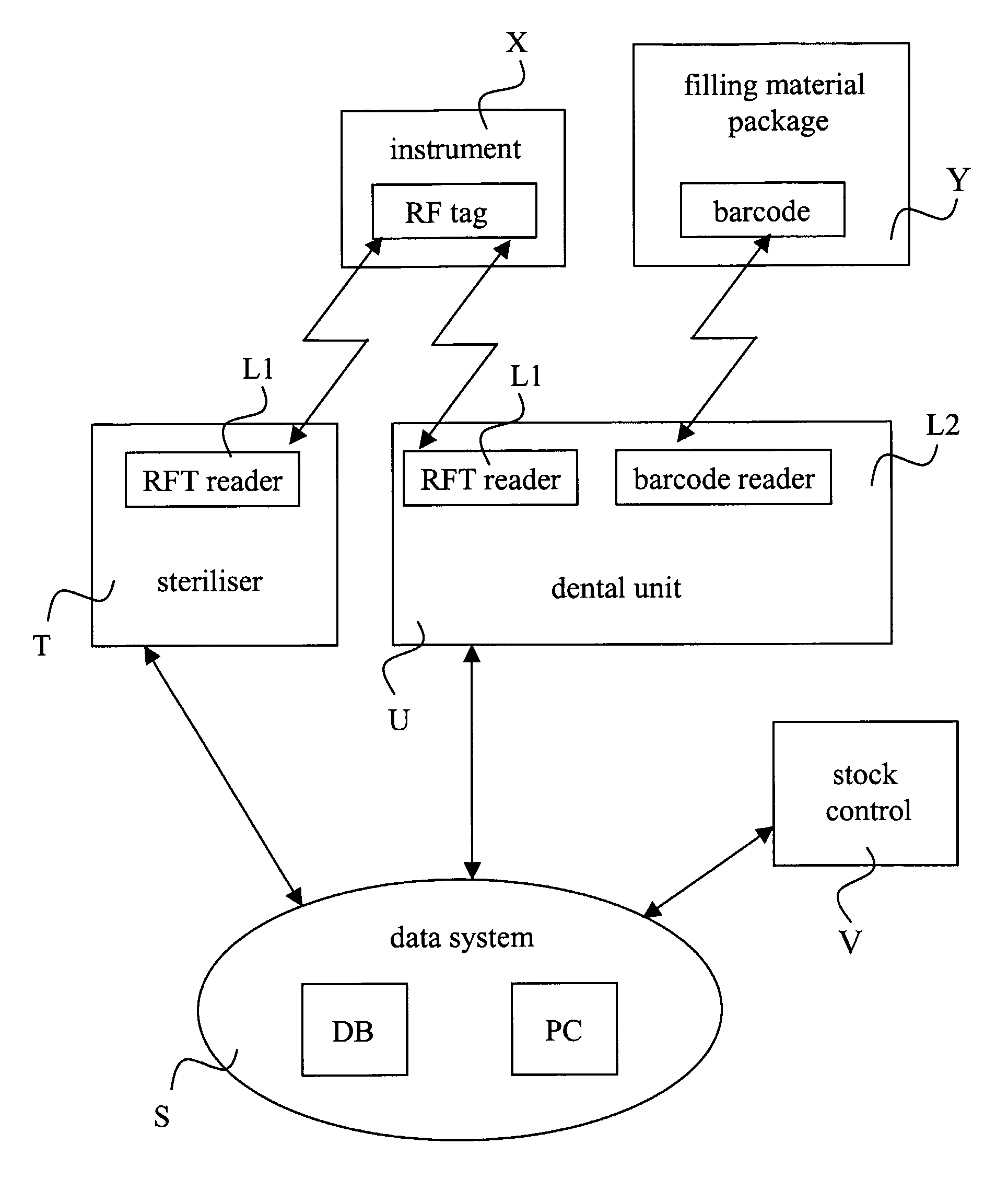

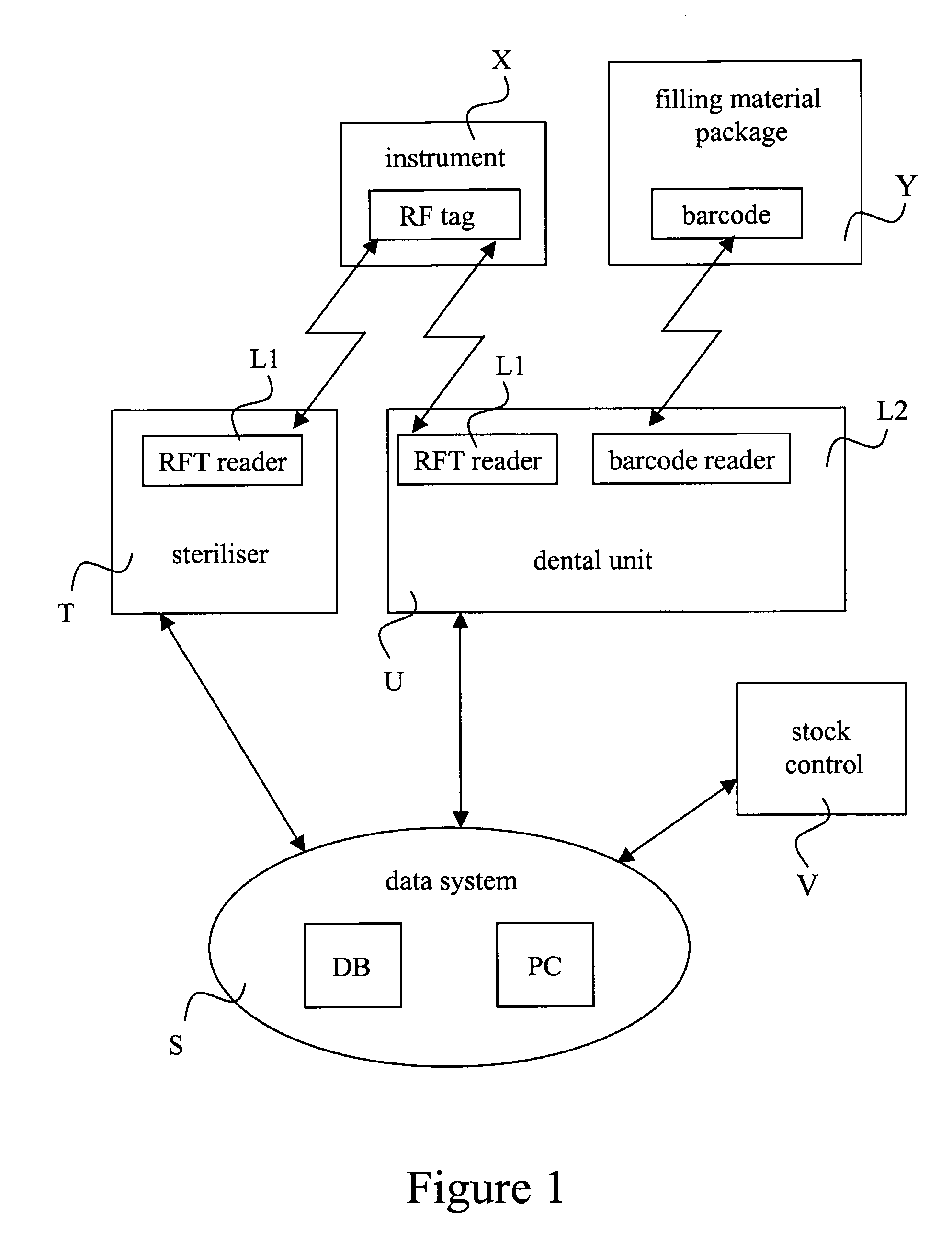

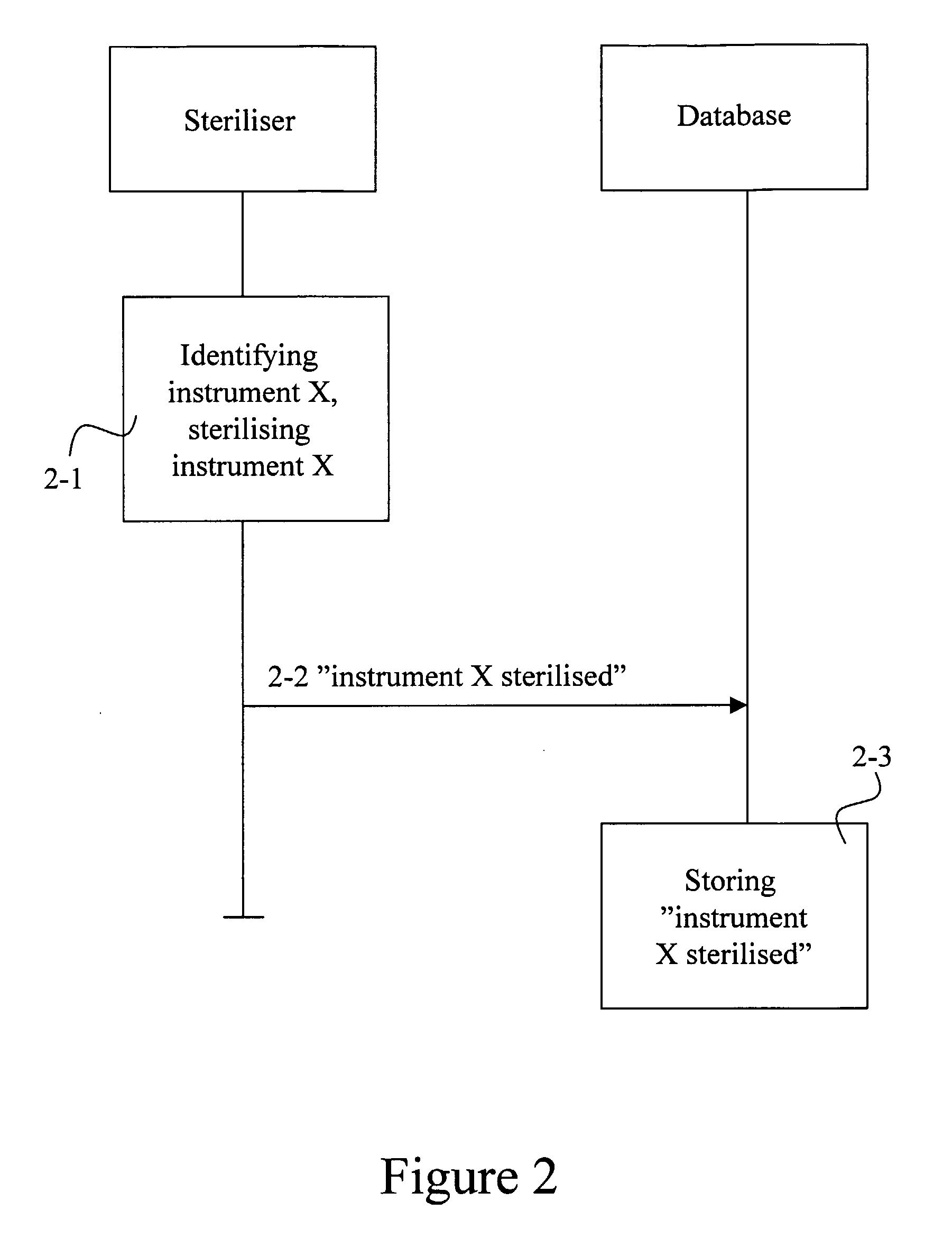

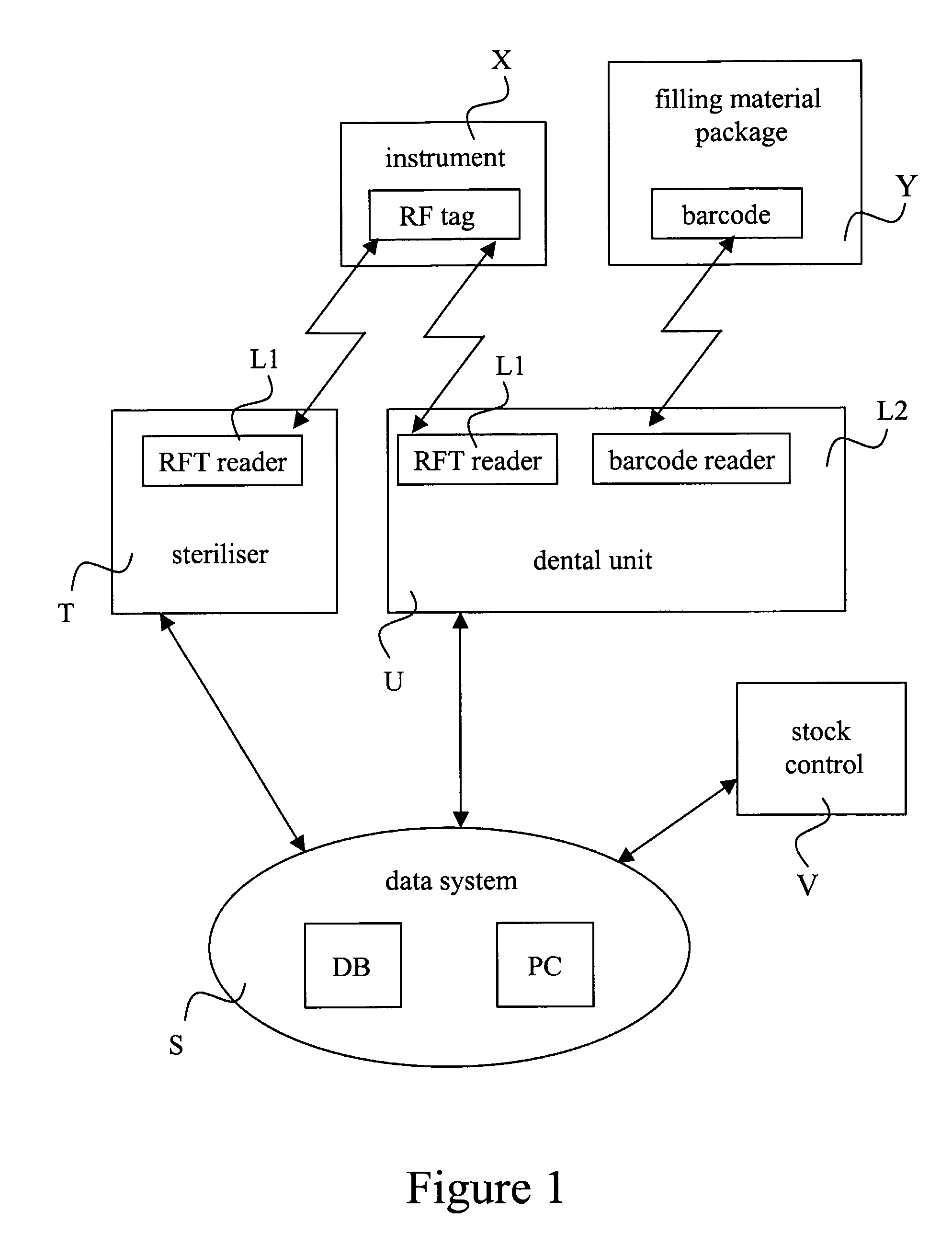

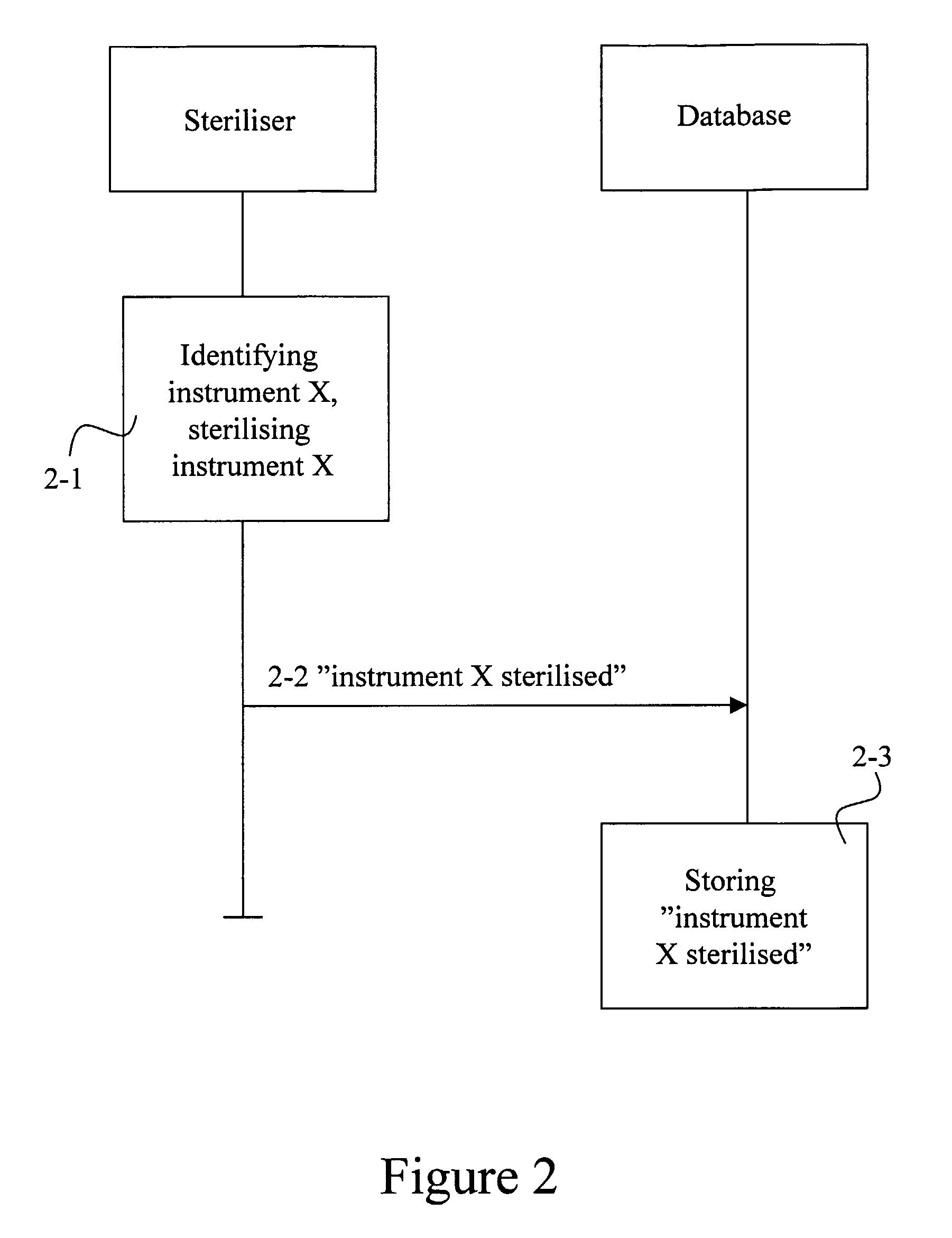

The invention relates to a data arrangement in connection with dental care, which arrangement includes at least one dental-care device (U, T) and a data system (S). In the arrangement, information related to a predetermined dental treatment event performed by the dental care device (U, T) is transmitted and stored in the data system (S), such as data of device parameters, instruments (X) or filling material (Y) or time used in the procedure. In the arrangement, the treatment event may be identified, for example, via the control system of the dental-care device (U, T) or by reading an identifier by means of an electronic reader device (L1, L2). The information related to the dental procedure is stored in the data system (S) patient-, instrument- or material-specifically so that it may be utilised afterwards, in case required.

Owner:PLANMECA

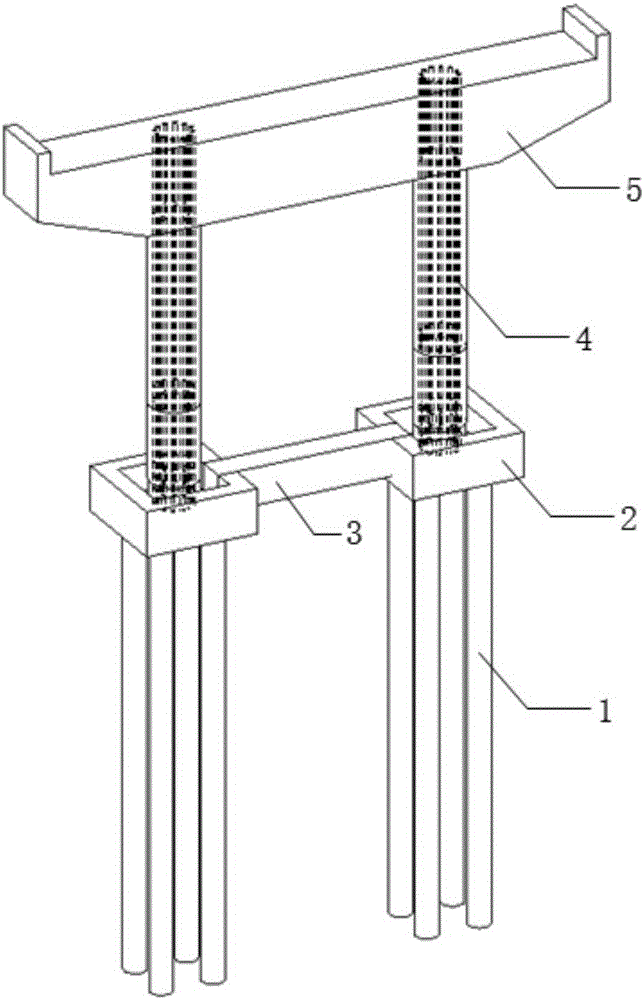

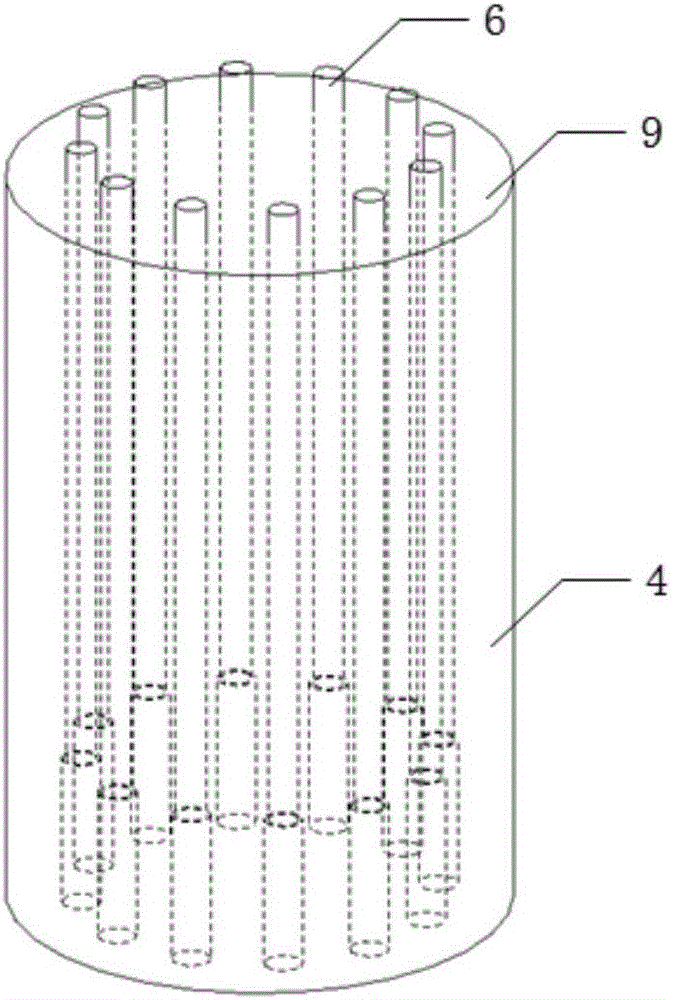

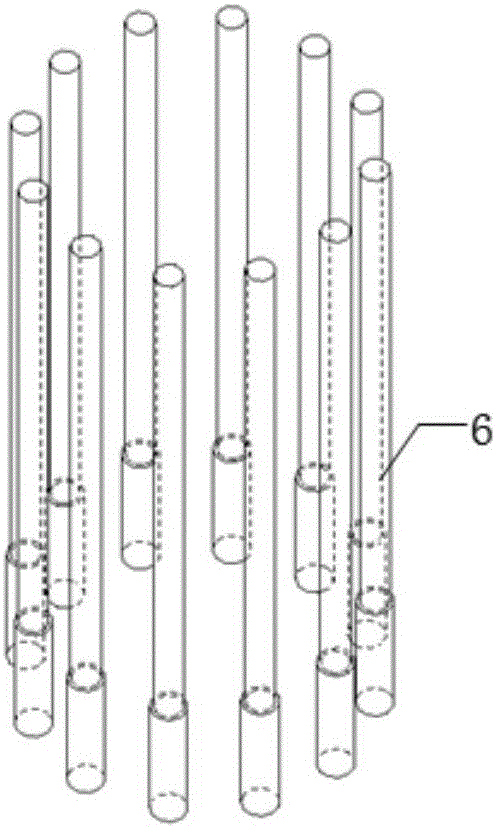

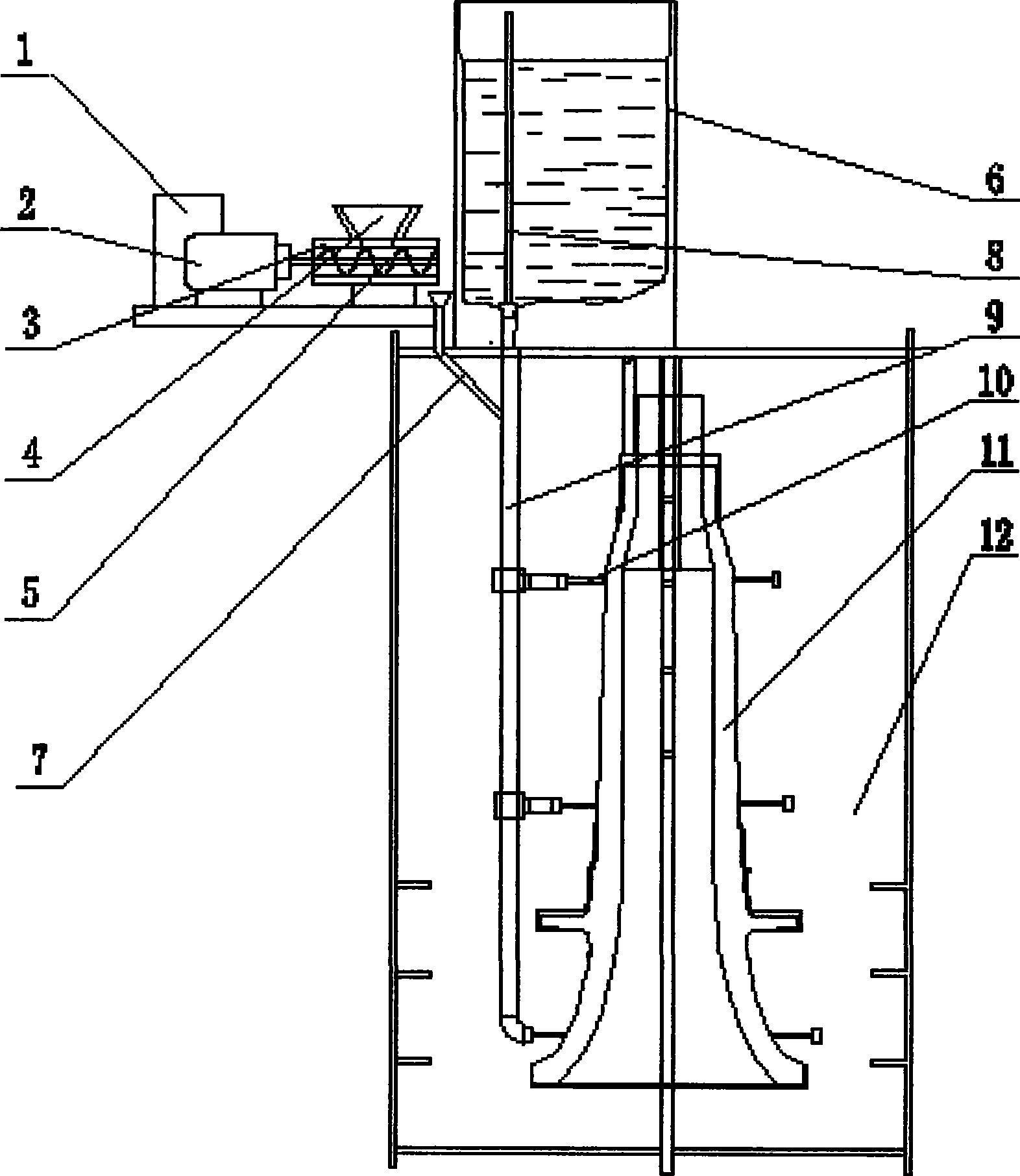

Bridge integrally-assembled pier and construction method

InactiveCN106049259ASimple connection processOvercoming the problem of difficult control of verticalityBridge structural detailsFoundation engineeringHigh strength concretePre stress

The invention discloses a bridge integrally-assembled pier and a construction method. The structural system of the bridge integrally-assembled pier is composed of integrally-assembled PHC pipe piles, assembled bearing platforms, an assembled tie beam, segment prefabricated pier bodies, an assembled cover beam and other components. The assembled bearing platforms, the assembled tie beam, the segment prefabricated pier bodies and the assembled cover beam are connected through steel pipes and a prestressing system. In the installation process, a prestressing tendon penetrates through all the components at first, positioning is completed through steel pipe sleeves under the self weight condition, the prestressing steel tendon is tensioned integrally, and a system is formed. According to the bridge integrally-assembled pier and the construction method, the components all adopt an industrialized production process and an assembly installation process, the construction period is shortened, and environment protecting is facilitated; a part of the components is made of high-strength concrete, so that materials are saved, and the construction cost is reduced; the detachable, replaceable and recycling effects are achieved, and energy saving and emission reducing are facilitated; and the seismic performance of the system is excellent.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST

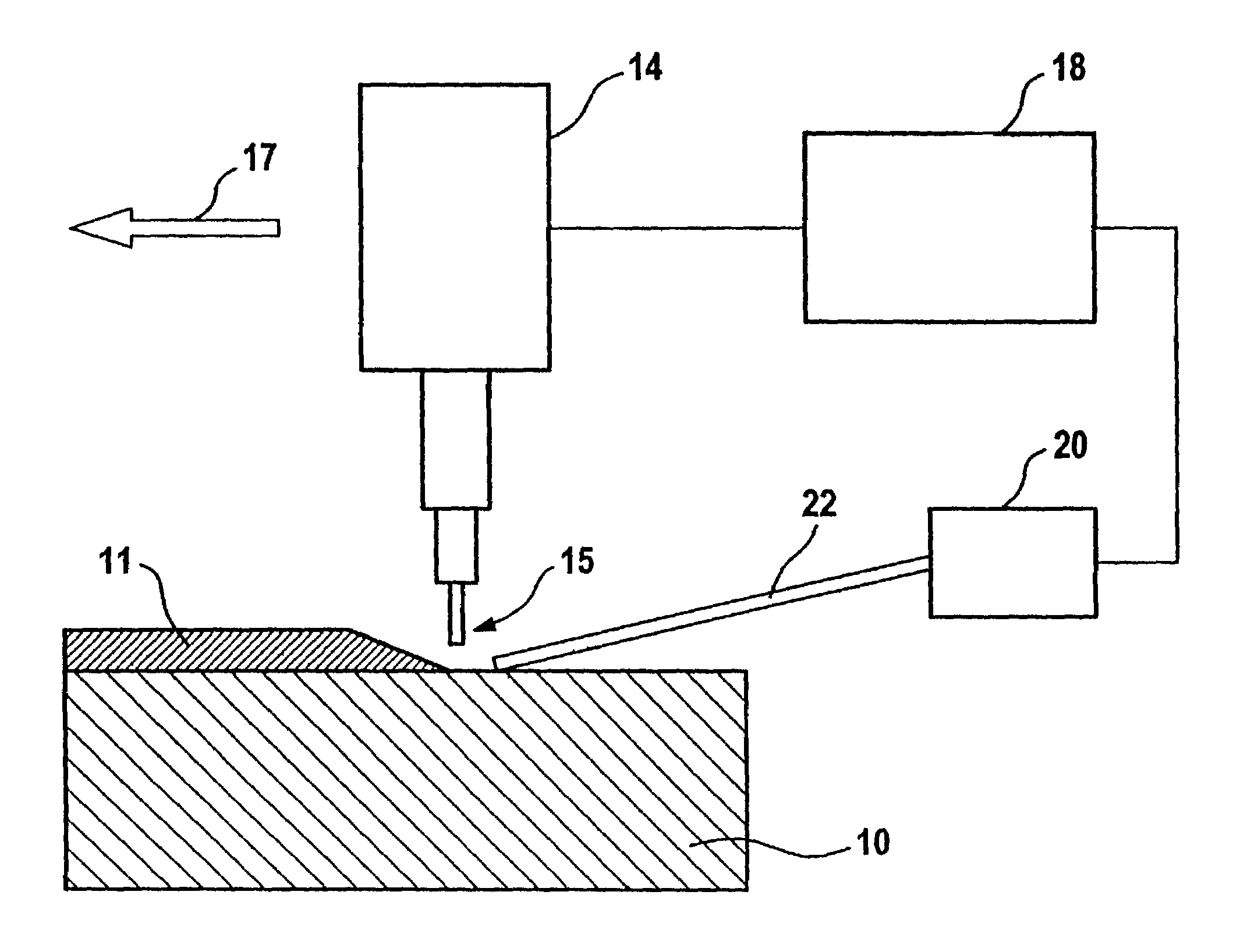

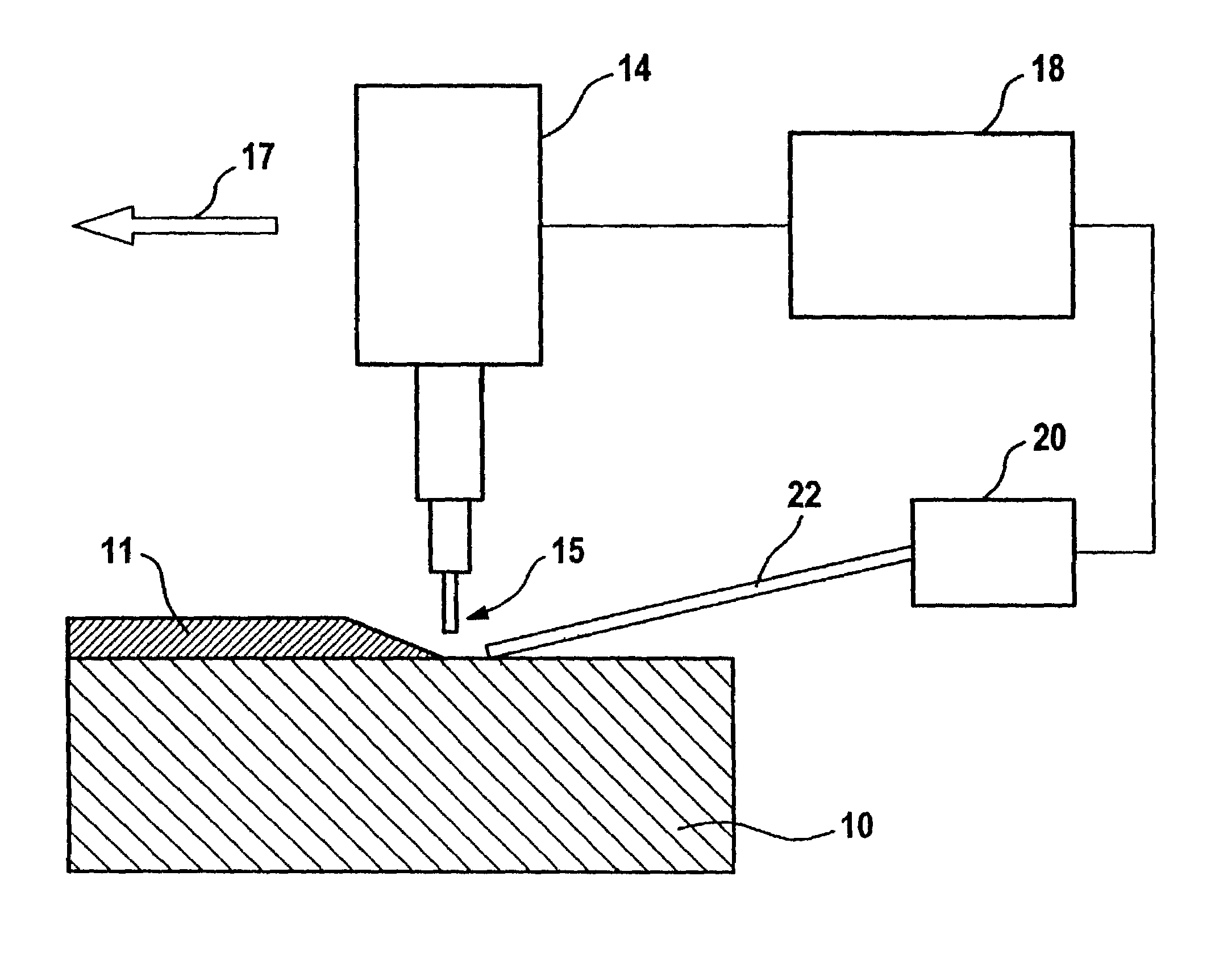

Method for removing coating from power unit components and device for carrying out the method

InactiveUS7452476B2Easy to implementPrevent removalVacuum gauge using ionisation effectsDecorative surface effectsFiberHigh energy

A method for the selective removal of one or more layers from a power unit component, e.g., a turbine blade of a heavy-duty turbine, using high-energy radiation of such a wavelength that the supplied energy is so strongly absorbed by the layer to be removed in each case that the removal threshold of the specific material of the layer to be removed is exceeded, while this removal threshold is not reached in the subsurface to be preserved, a spectrometer connected to a control unit via a light-conducting fiber cable such that the method-specific characteristic values are determinable by spectroscopic methods during the removal of the respective layer and are used for the self-regulating process limitation.

Owner:MTU AERO ENGINES GMBH

Ultra-strong refractory steel

The invention supplies a supper refractory steel. The feature is the ingredients and proportion: C is 0.2-0.45%, Cr is 22-28%, Ni is 3.5-13%, Si is 0.1-0.4, N is 0.1-0.4, RE is 0.03-3%, Mo is 0.15-2.3%, W is 0.15-2.3%, Co is 0-13%, Mn is 1-13%, Mg is 0.0005-0.10%, and the other ingredients is Fe and impurity.

Owner:张光华

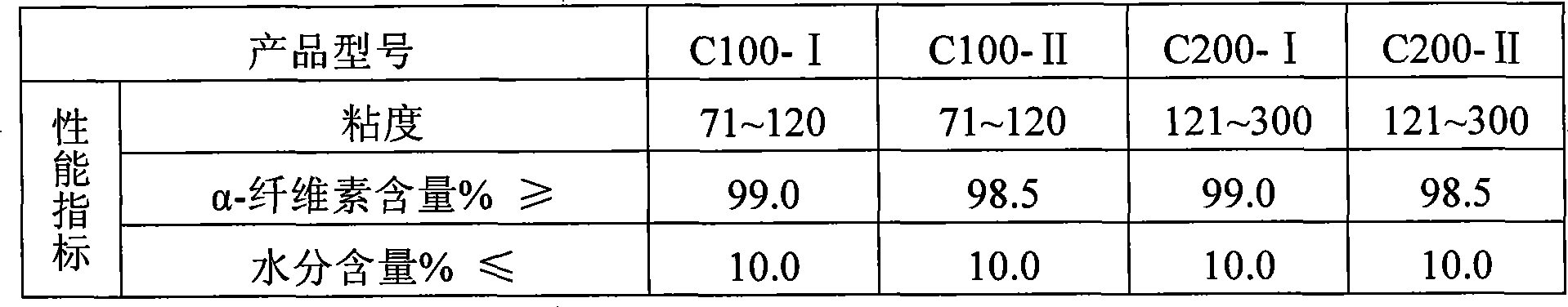

Method for producing cotton pulp for acetate fibre

ActiveCN101532185AReduce beating power consumptionConducive to penetrationArtificial filaments from viscoseFilm (photographic)Cotton linters

The invention discloses a preparation method of cotton pulp for acetate fibre. The method comprises the steps of using cotton linter as a raw material, opening the cotton, cutting, washing, mixing liquid medicine, reacting and manufacturing with the pulp; after opening the cotton, sending the cotton linter to a double-roll pulping machine, accomplishing the cutting, washing and liquid medicine mixing steps in the double-roll pulping machine to form slurry; after the liquid medicine is mixed uniformly, putting the slurry in a bin to perform a reaction, and finally obtaining the cotton pulp for acetate fibre. The product is specially used for production of high-quality acetate fibre, comprising acetate fibre filament yarns, cigarette holder textile cables, electronic display screens, plastics and photographic films. The invention uses the double-roll pulping machine to replace multiple sets of apparatuses in the traditional technology. The cotton pulp for acetate fibre prepared by the method of the invention has the characteristics of good evenness, low energy consumption, high efficiency and low pollution.

Owner:YIBIN GRACE GROUP CO LTD

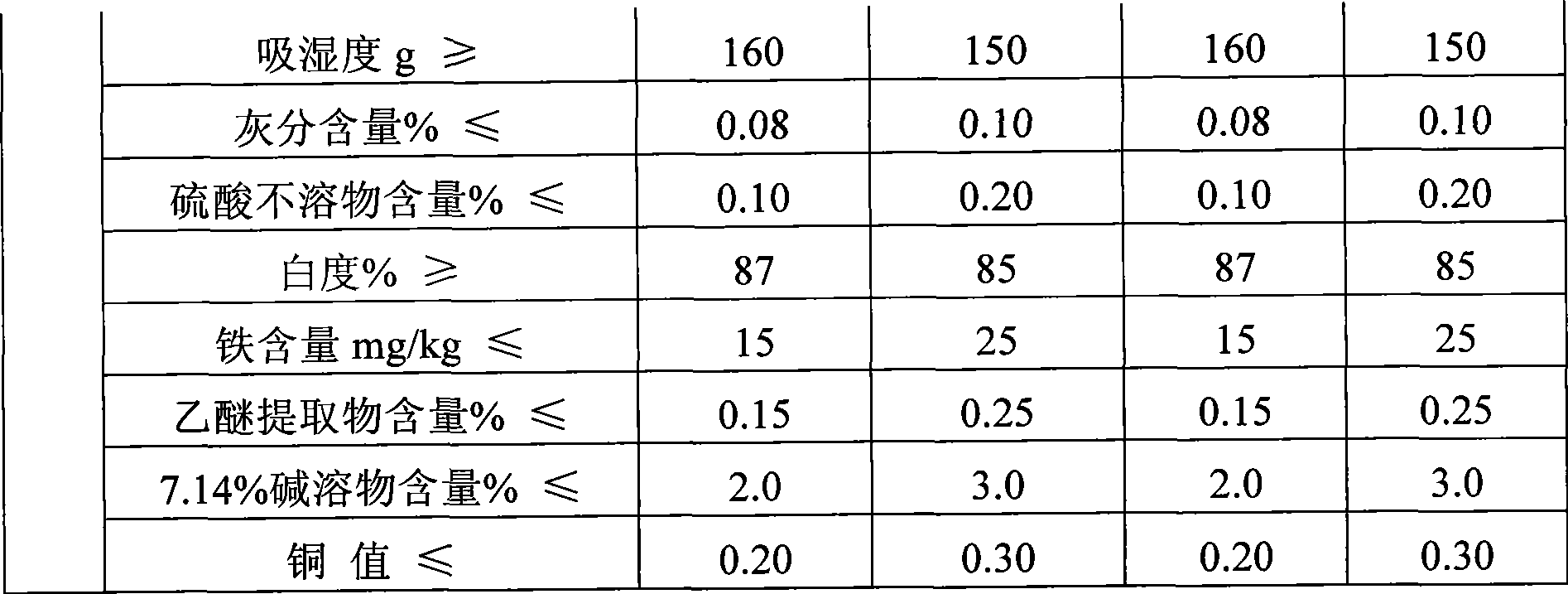

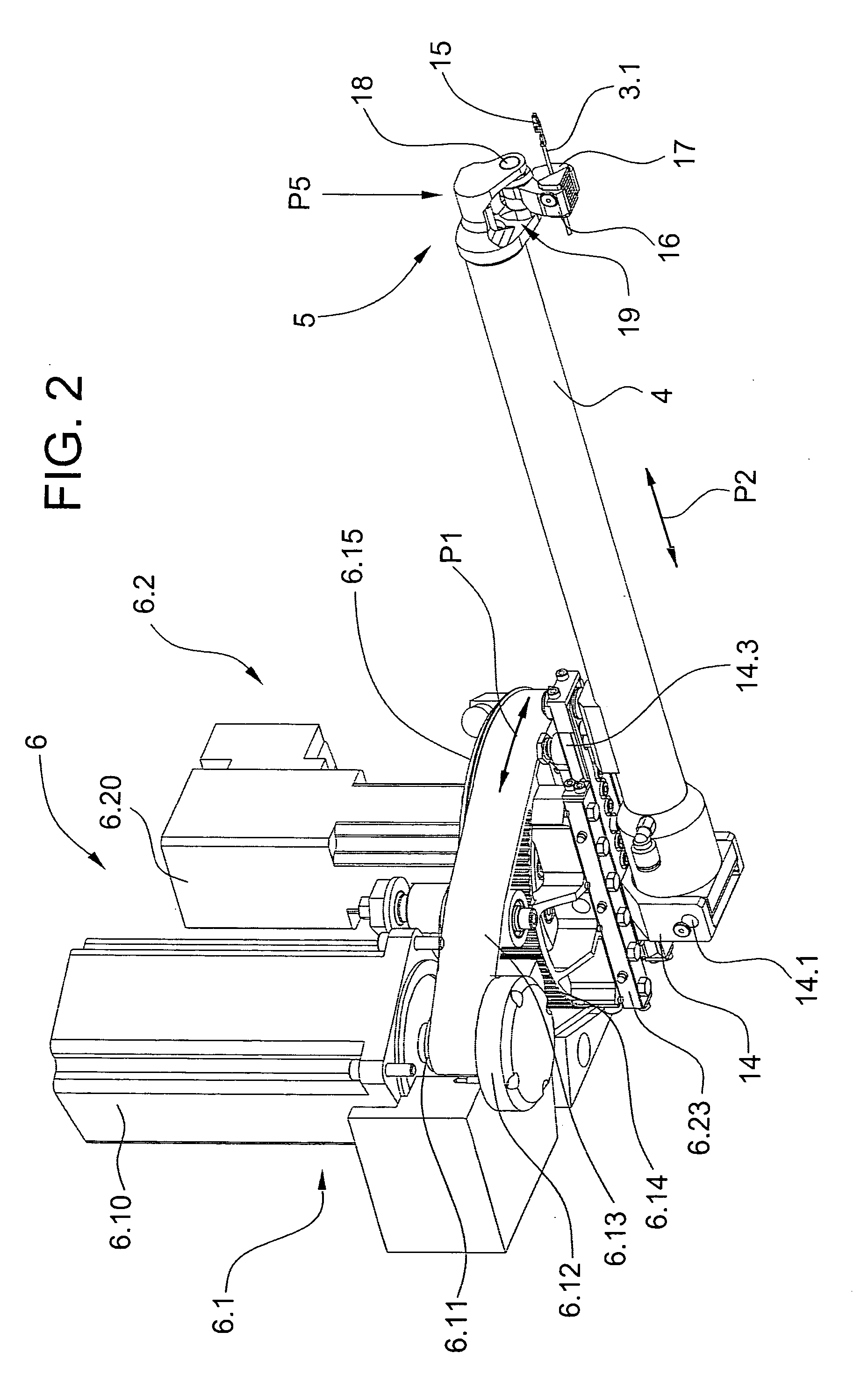

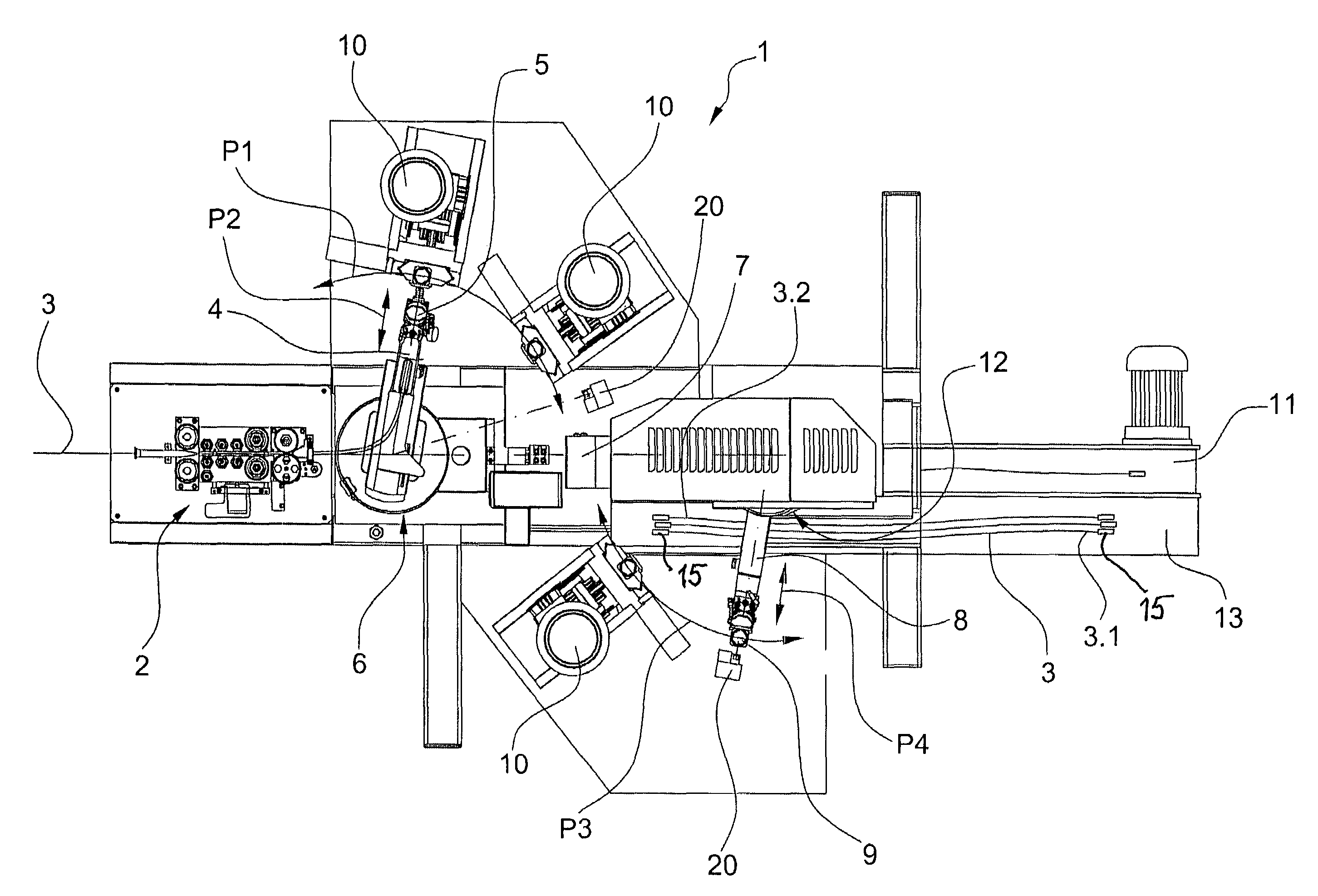

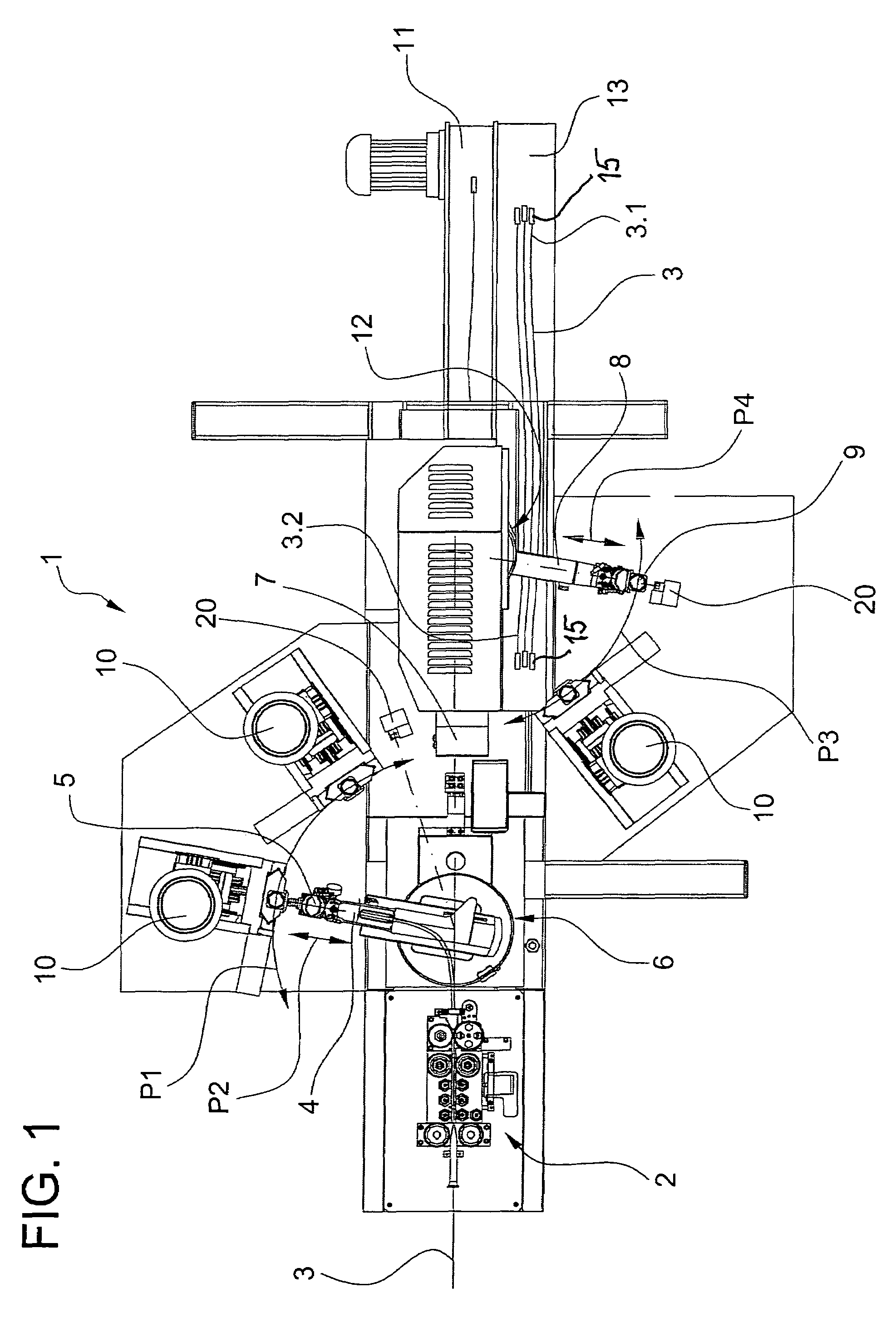

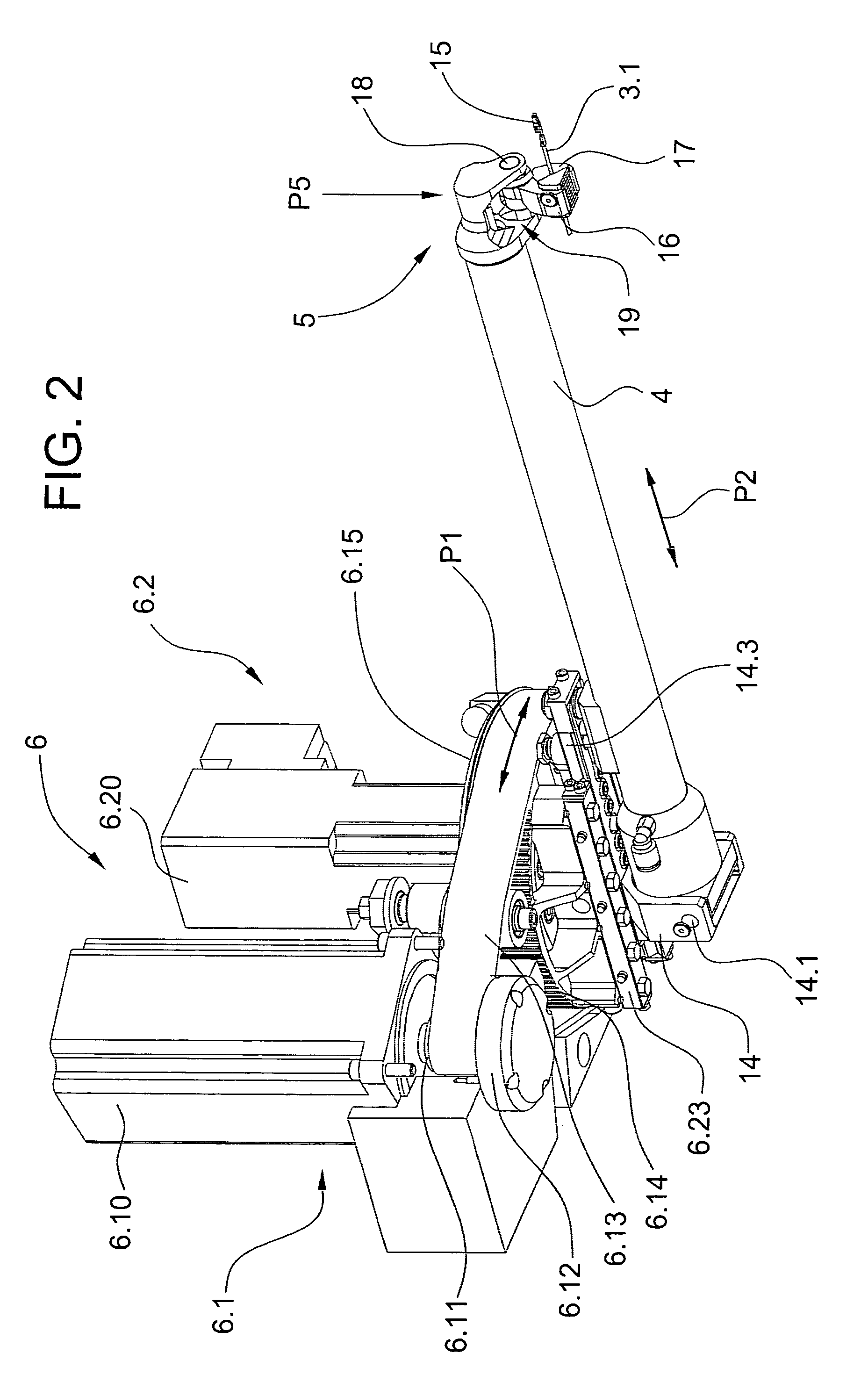

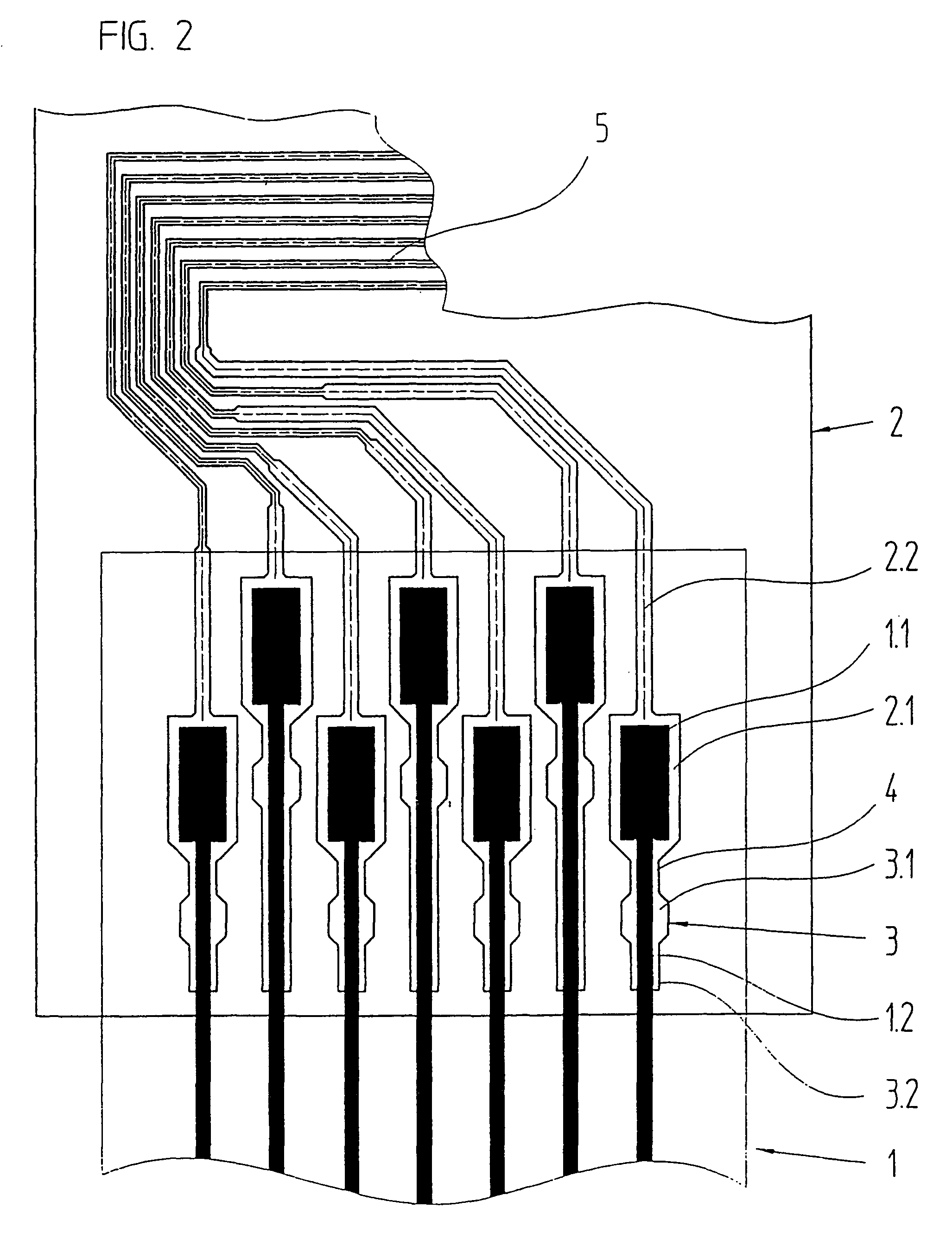

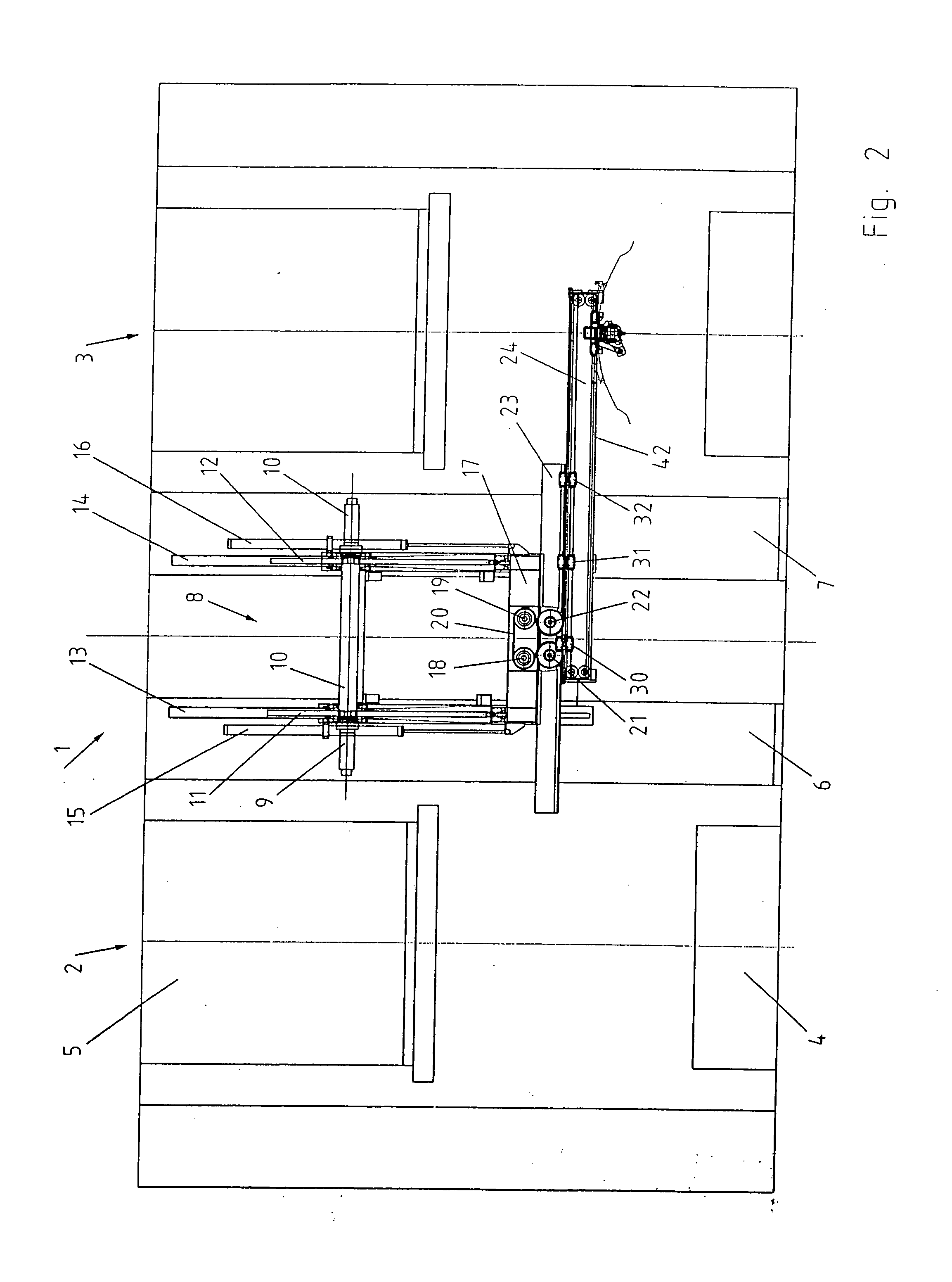

Inspection apparatus and method for wire-processing machine

InactiveUS20050050722A1Avoid disadvantagesEasy to set upContact member manufacturingElectrically conductive connectionsLinear motionEngineering

A wire-processing apparatus has a belt drive that guides a wire to a first swivel arm with a first gripper. The leading end of the wire is fed to processing stations by setting the first swivel arm into a swivel motion and / or a linear motion. The lagging end of the wire is fed to the processing stations by setting a second swivel arm with a second gripper into a swivel motion and / or a linear motion. A holder is used to inspect the wire end connection, or the crimp connection, produced in the automated wire-processing operation, wherein the linear movement of the grippers is also used for the automated inspection of the wire end connection.

Owner:KOMAX HOLDING

Inspection apparatus for wire-processing machine

InactiveUS7603768B2Avoid disadvantagesEasy to set upLine/current collector detailsOther manufacturing equipments/toolsWire rod

Owner:KOMAX HOLDING

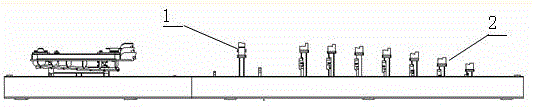

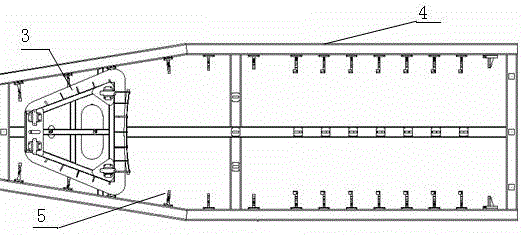

Assembly welding process method for aluminum structure ceiling of driver cab of motor train unit

ActiveCN104384740AReduce the workload of the synthesis processShorten the compositing timeWelding/cutting auxillary devicesAuxillary welding devicesModularityEngineering

The invention relates to an assembly welding process method for an aluminum structure ceiling of a driver cab of a motor train unit. The assembly welding process method is characterized in that (1) at the premise of not changing the integral structure of the original structure, ceiling modules are separated, the structure of the original driver cab is re-divided, one part of structure is separated from a left side wall structure and a right side wall structure, and is used as a longitudinal edge beam of the ceiling structure, and then bulk parts which cannot be singly combined in the original structure can form the ceiling welding structure; (2) a welding tooling adopting the reverse assembly and outer positioning method is used for positioning and clamping, the welding sequence of the new ceiling structure is adjusted, the welding of a ceiling window frame structure is firstly completed, then the welding of a ceiling skeleton and a front window frame is completed, and finally the welding of a ceiling skin and the skeleton is completed, so a five-shaft processing center can complete processing at one time. The assembly welding process method has the advantages that the existing production technique of the aluminum structure ceiling of the driver cab of the motor train unit is a full new technique, the product quality of the ceiling part is improved, the assembly welding difficulty of the aluminum structure ceiling of the driver cab is decreased, the production cycle and labor intensity of the driver cab assembly are improved, the production modularizing of the driver cab is improved, and the quality is conveniently guaranteed.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

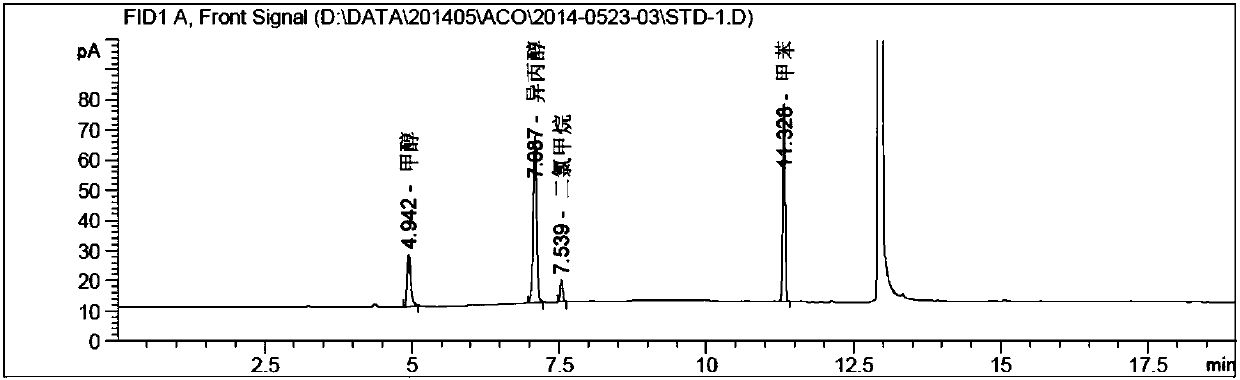

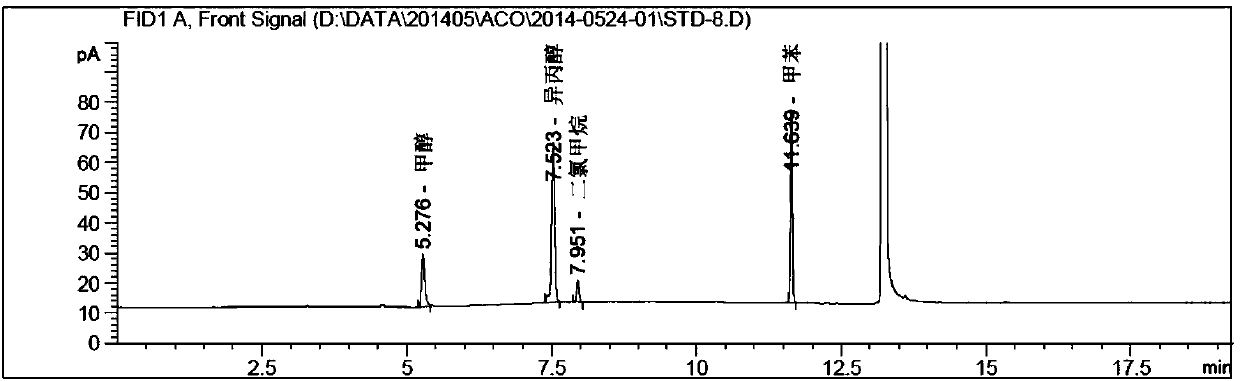

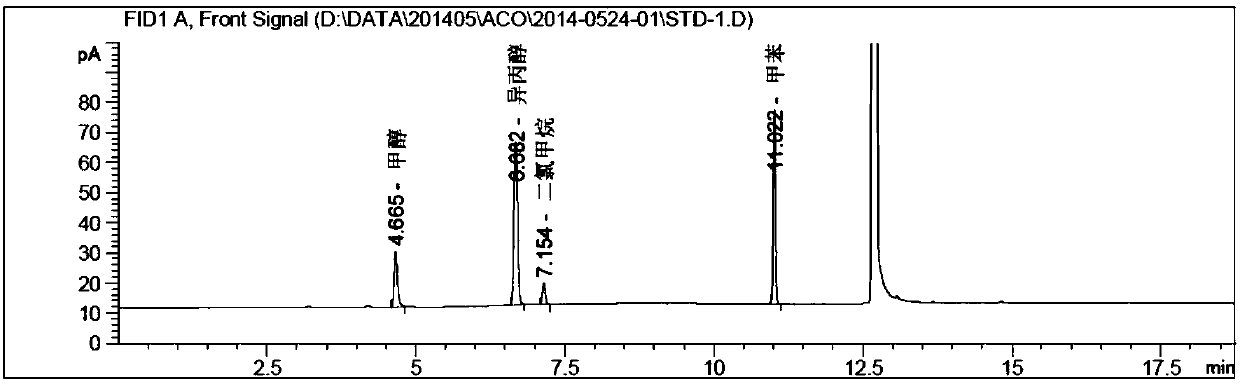

Method for determining solvents residual in acotiamide hydrochloride bulk drug

The invention discloses a method for determining solvents residual in an acotiamide hydrochloride bulk drug. The method adopts the following analysis conditions: the chromatographic column adopts a capillary chromatographic column with 6% cyanopropylphenyl 94% polydimethylsiloxane as the stationary phase; a reference substance solution is injected multiple times in a split flow manner, a sample solution is injected in the split flow manner, the carrier gas is nitrogen, the introduction is carried out by using a headspace injector, and detection is performed after temperature programming; and the detector adopts an FID detector. Methanol, isopropanol, dichloromethane and toluene in the acotiamide hydrochloride bulk drug are rapidly and efficiently separated under same chromatographic conditions through the method in order to effectively control the quality of acotiamide hydrochloride. The detection method has the advantages of strong specificity, high detection sensitivity, high precision, high accuracy, convenience in operation, and effective control of the product quality.

Owner:WATERSTONE PHARMA WUHAN

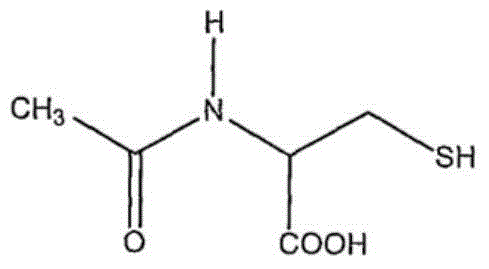

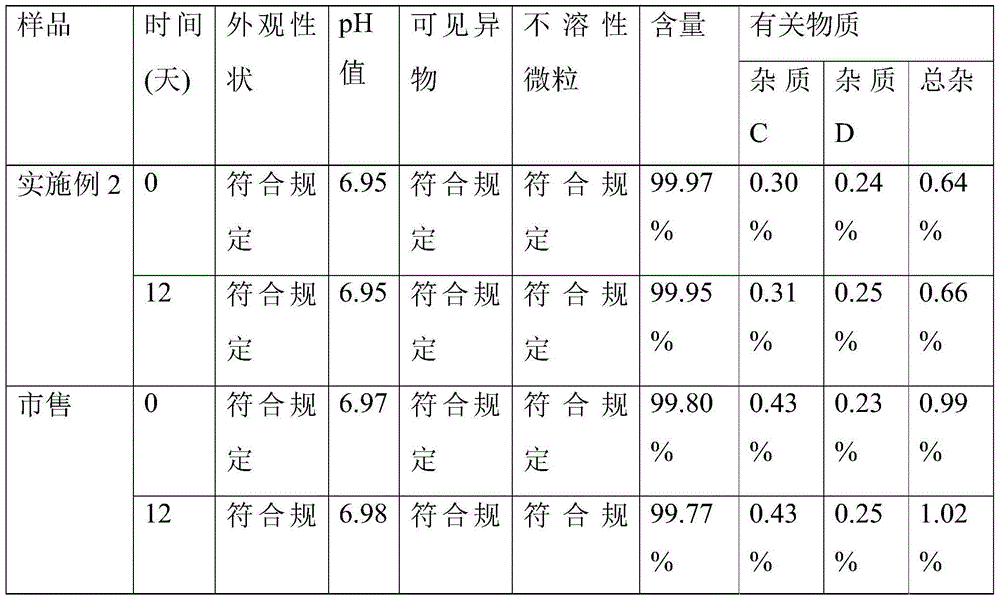

Inhalant acetylcysteine solution and preparation method of inhalant acetylcysteine solution

ActiveCN104800854AGood quality assuranceImprove securityOrganic active ingredientsPharmaceutical delivery mechanismMedicineCysteic acid

The invention belongs to the field of a medicine preparation and relates to an inhalant acetylcysteine solution and a preparation method of the inhalant acetylcysteine solution. Physiological seawater is added into the solution, so that the sensitization of the acetylcysteine solution is effectively reduced.

Owner:WUHAN WUYAO SCI & TECH

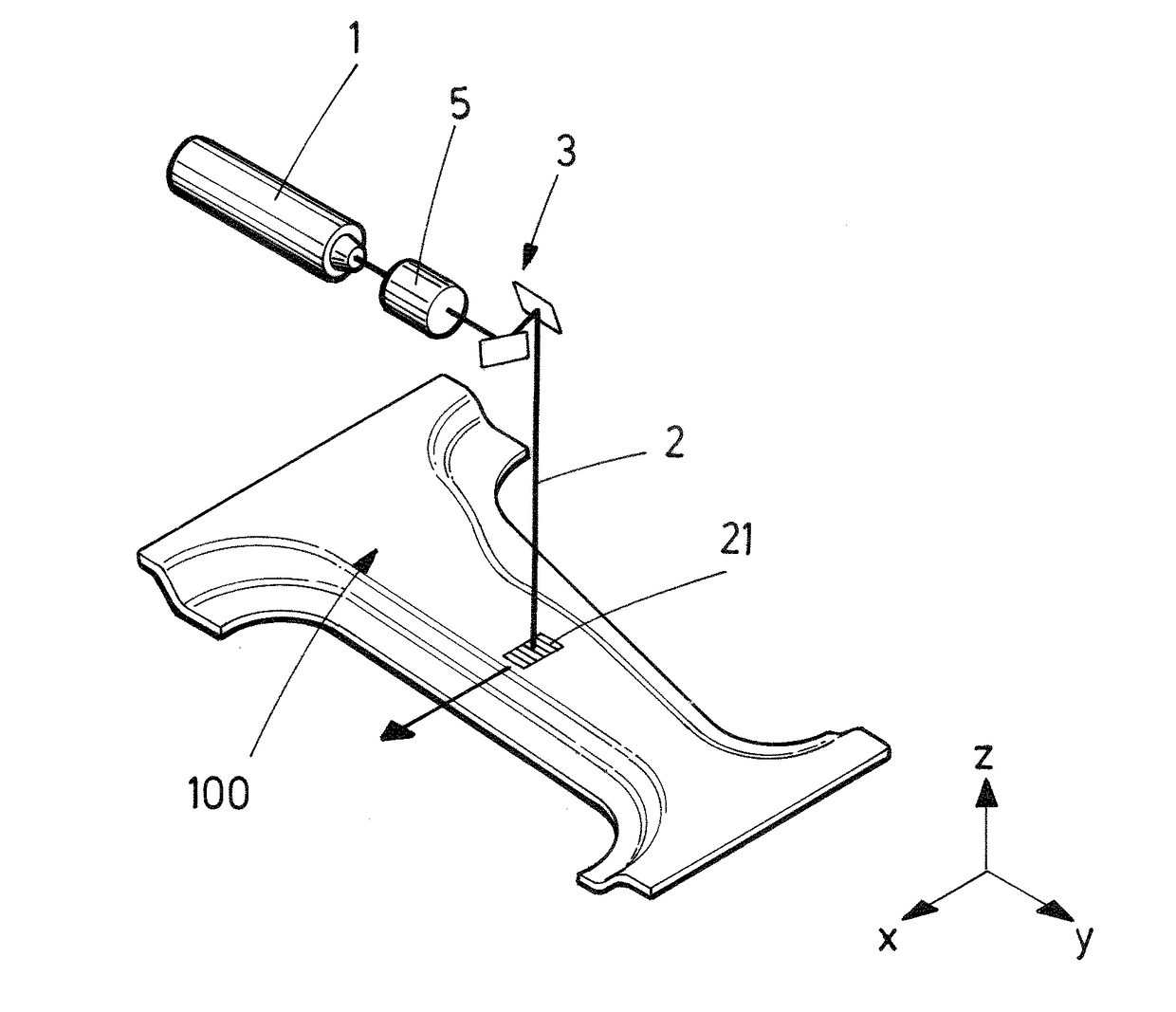

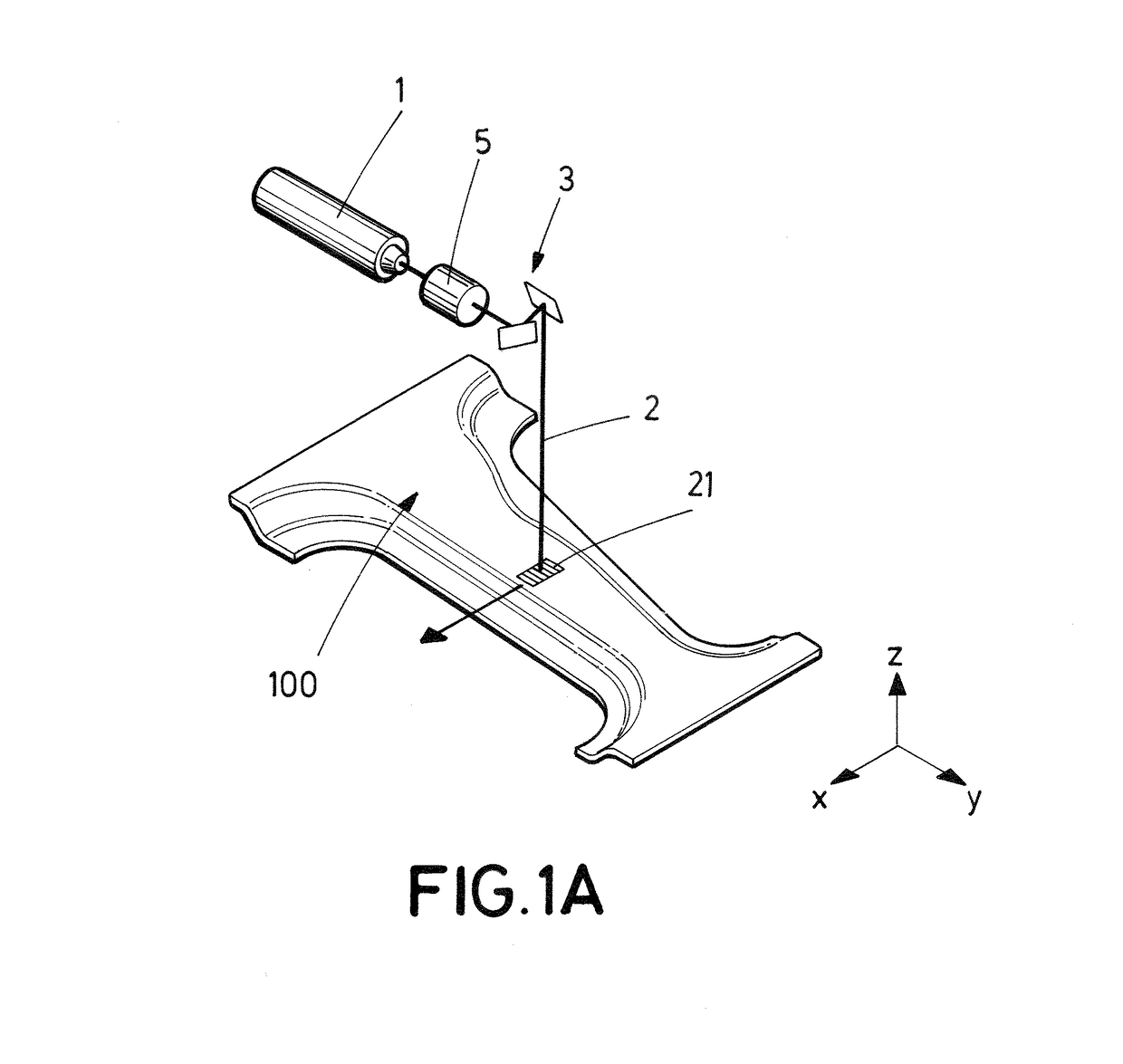

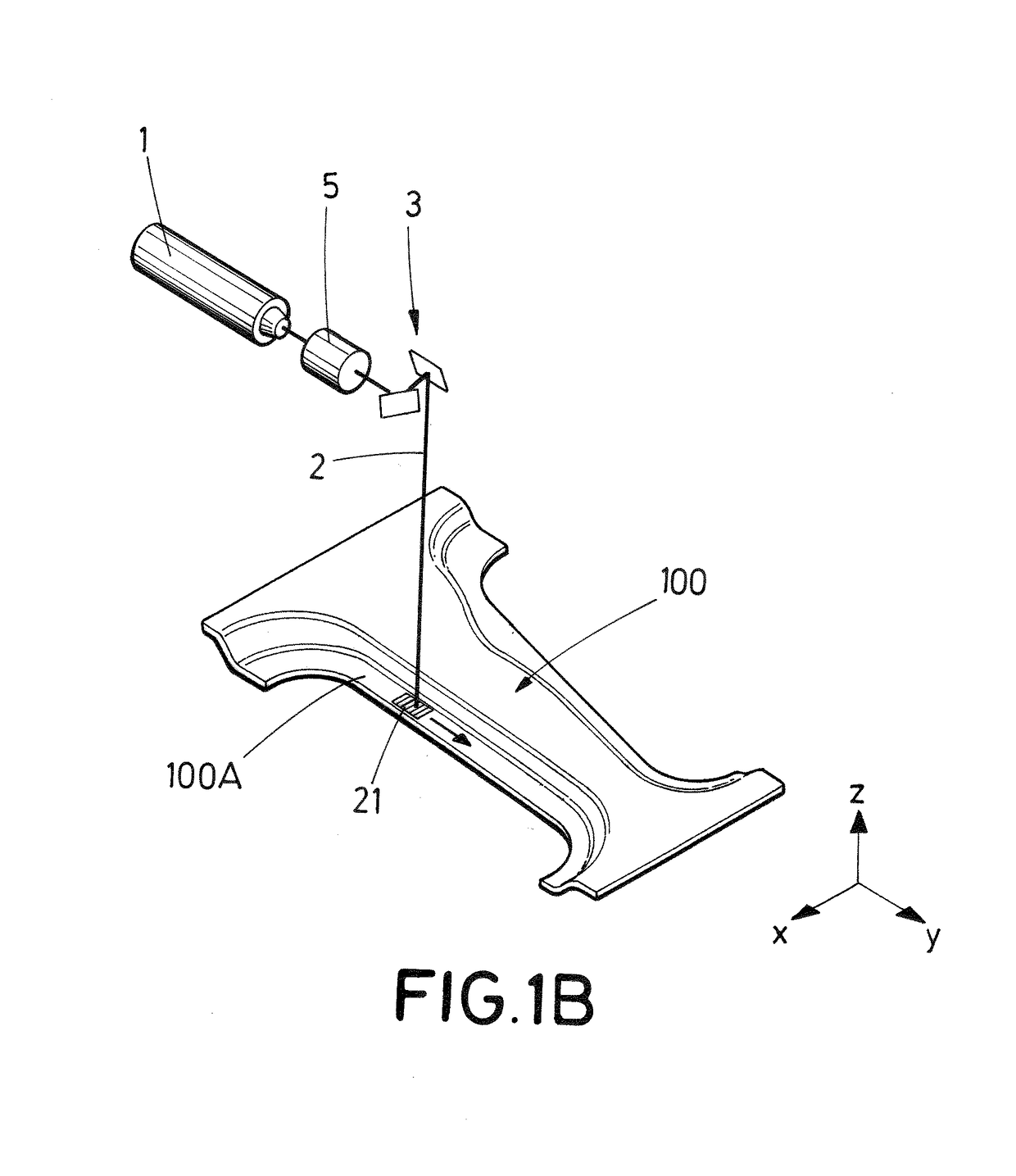

Method and system for heat treatment of sheet metal

ActiveUS20180071864A1Improve heating qualityAddressing Insufficient ControlFurnace typesIncreasing energy efficiencyLight beamMetal

A method for heat treatment of an object of sheet metal, including heating at least one selected portion of the object using an energy beam, where the beam is projected onto a surface of the object so as to produce a primary spot on the object, the beam being repetitively scanned in two dimensions in accordance with a first scanning pattern so as to establish an effective spot on the object, the effective spot having a two-dimensional energy distribution, where the effective spot is displaced in relation to the surface of the object to progressively heat said at least one selected portion of the object.

Owner:IKERGUNE A I E

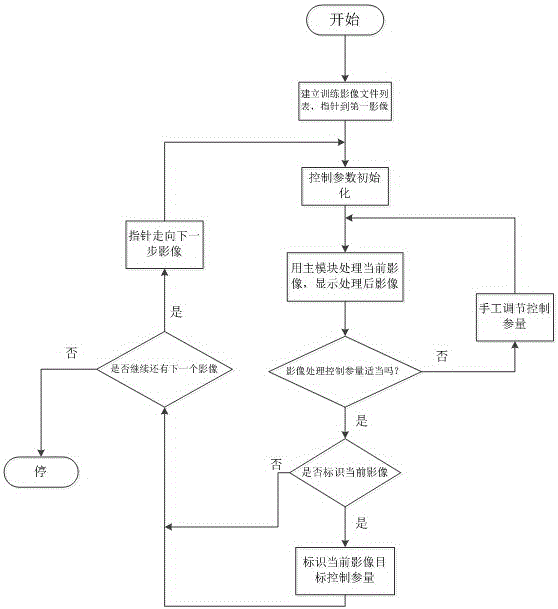

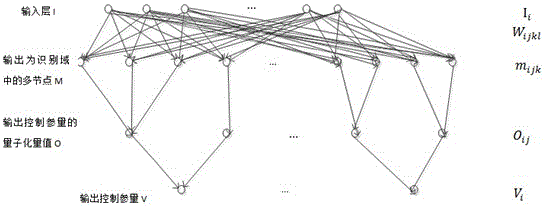

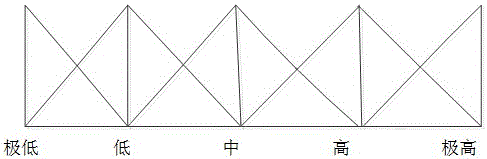

Intelligent optimal selection method of medical science X-ray image processing control parameters

ActiveCN106372719AGood quality assuranceBiological neural network modelsImage data processing detailsPattern recognitionImaging processing

The present invention relates to an intelligent optimal selection method of medical science X-ray image processing control parameters. The method comprises: collecting and arranging an X-ray image sample set which includes original images in each inspection condition and the corresponding control parameters; then, building a neural network model with a multi-layer structure, performing training and checking; and finally, through the checking neural network model, combing a CR / DR image processing main program, applying the neural network model to in actual. The intelligent optimal selection method of the medical science X-ray image processing control parameters employs the neural network model method to identify the types of the images and the conditions when the images are taken in, and allows the types of the images and the conditions to contact with the appropriate control parameters so as to provide better quality guarantee for the CR / DR imaging.

Owner:ZHEJIANG RADIOLOGY INFORMATION TECH

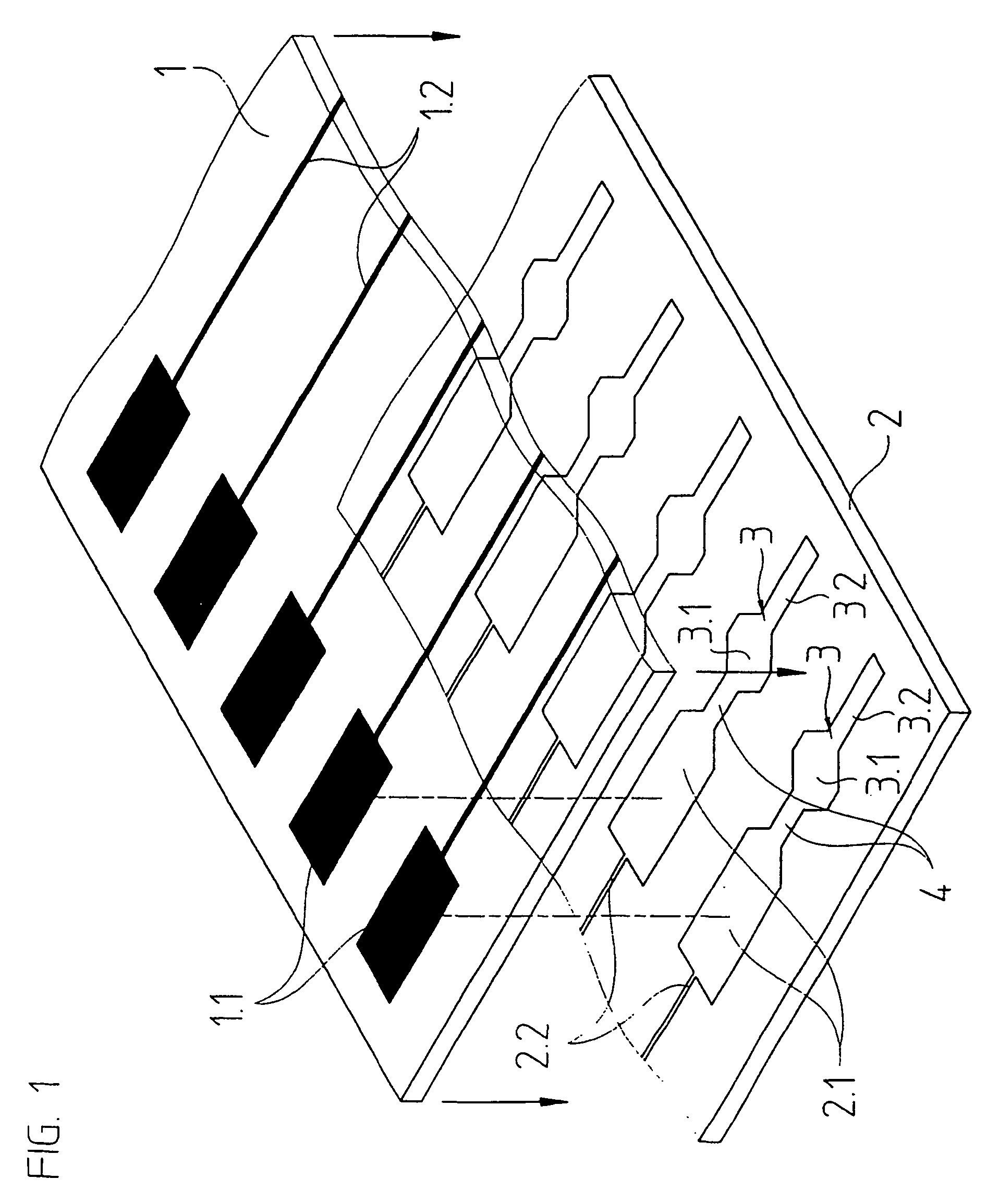

Composite comprised of flat conductor elements

InactiveUS7223921B2Sufficient protectionImprove welding qualityPrinted circuit assemblingFinal product manufactureElectrical conductorMaterials science

A composite of at least two flat elements that includes a first support substrate having a first solder pad, and a second support substrate having a second solder pad that is soldered together with the first solder pad. Strip conductor structures are applied to the first support substrate and the second support substrate and a link area that connects a solder shunting area with the first solder pad, wherein the link area is narrower than the first solder pad and the solder shunting area.

Owner:DR JOHANNES HEIDENHAIN GMBH

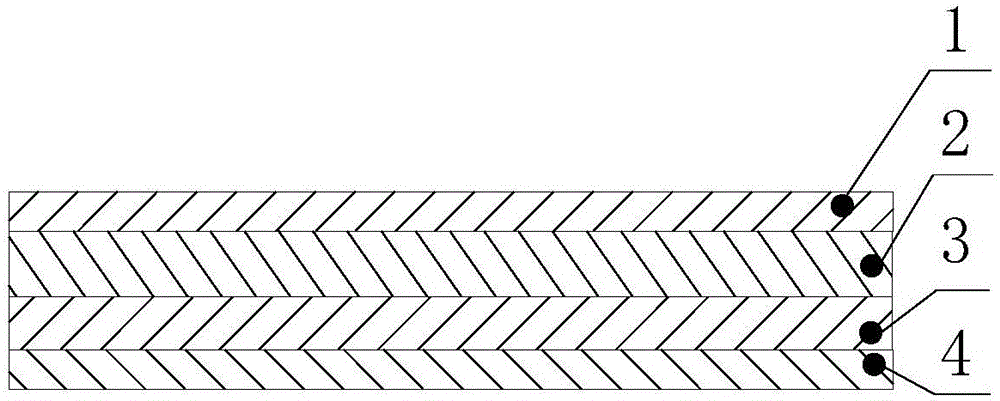

Low-temperature, heat-sealing and inflation-resistant CPP aluminum-plated film and preparation method thereof

ActiveCN105856775AIncrease the speed of the packageIncrease productivityFlexible coversWrappersLow-density polyethyleneCo extrusion

The invention belongs to the technical field of aluminum-plated films and provides a low-temperature, heat-sealing and inflation-resistant CPP aluminum-plated film. The invention is characterized in that, the low-temperature, heat-sealing and inflation-resistant CPP aluminum-plated film is formed through the co-extrusion process of four layers, namely a heat-sealing layer, a first core layer, a second core layer and an aluminum-plated layer, wherein the four layers are sequentially arranged and casted. The mass percentages of the heat-sealing layer, the first core layer, the second core layer and the aluminum-plated layer are respectively 19-20%, 28-29%, 33-34%, and 17-18%. The heat-sealing layer is prepared through mixing up ternary random copolymer polypropylene resin, ethylene-vinyl acetate copolymer (EVA) and a modifying agent. The first core layer is prepared through mixing up polypropylene resin and metallocene polyethylene. The second core layer is prepared through mixing up polypropylene resin, polyamide resin and low-density polyethylene. The aluminum-plated layer is prepared through mixing up copolymer resin and a reinforcing agent. An aluminum-plated film prepared through the above method is good in toughness, and the temperature of the heat-sealing layer can be reduced.

Owner:HUBEI DEWEI PACKAGING TECH

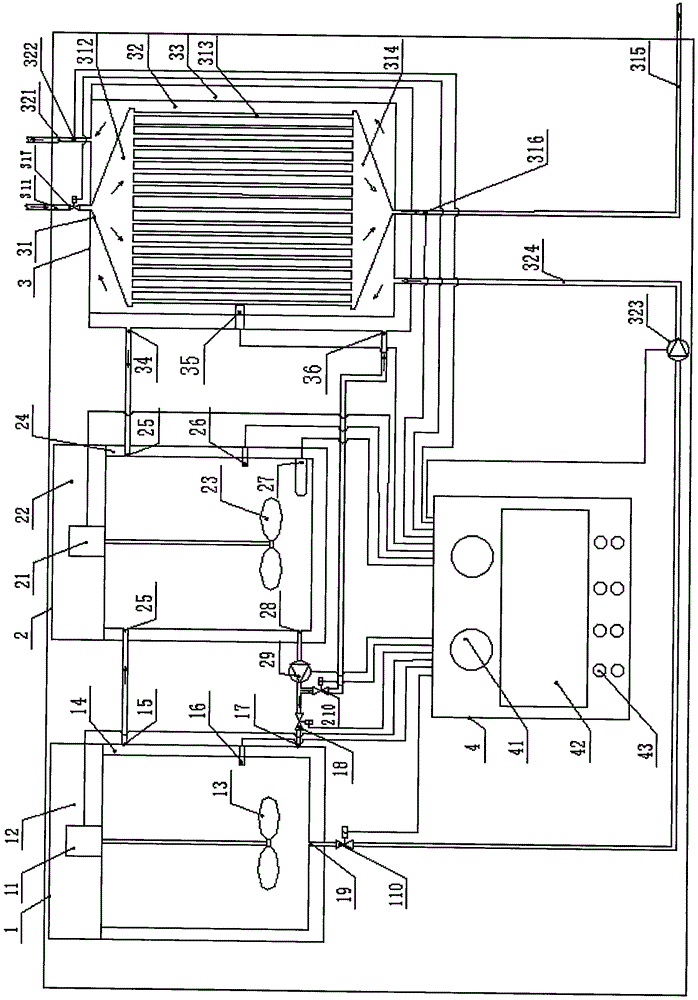

Intelligent hematodialysis device

The invention relates to the technical field of medical equipment, in particular to an intelligent hematodialysis device. The intelligent hematodialysis device comprises a dialyzate barrel, a hot water barrel, a dialysis barrel and a control cabinet; a stirring structure, a heat preservation jacket, an electric heater and a temperature sensor are arranged in the hot water barrel, the hot water barrel is connected with the dialyzate barrel and the dialysis barrel through pipelines, and a hot water pump pumps hot water into hot water jackets of the dialyzate barrel and the dialysis barrel. The control cabinet comprises an alarm, a touch screen, buttons, a frequency converter and input and output terminals. Temperature and speed of blood and dialyzate are constant and beneficial for stabilizing the dialysis process, an intelligent programmable PLC is adopted, and the temperature and speed of the blood and the dialyzate and other related technical parameters in the dialysis process are monitored and adjusted in real time, which is beneficial for conducting dialysis safely and ensuring dialysis quality.

Owner:卢新明

Hot-melting road-marking coating and preparation method thereof

InactiveCN104592852AImprove liquidityWell mixedPowdery paintsReflecting/signal paintsRoad surfaceUltra fine

The invention provides a hot-melting road-marking coating and a preparation method thereof. The coating comprises the following components in percentage by weight: 13%-17% of C5 petroleum resin, 0.5-1.5% of EVA, 0.5-1.5% of PE wax, 0.5-1% of dioctyl ester, 3-4% of a pigment, 17%-22% of glass microspheres, 16%-21% of quartz sand, 36%-42% of ultra-fine talcum powder and 0.2%-0.4% of permeable crystallization-type water-resistant rubber powder. The fluidity of the coating is increased, the heating and stirring time is decreased and the production energy consumption is saved. The construction efficiency is improved, the melting temperature is decreased and the production energy construction is saved and meanwhile, the coating has the advantages of very strong adhesion force, abrasion resistance and long service life, good quality assurance degree and stable product quality.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES +1

Purslane vinegar and production method thereof

ActiveCN103045453AStrong vinegar aromaJuice is clear and transparentMicroorganism based processesVinegar preparationHealth protectionFood additive

The invention provides purslane vinegar. Purslane, as a main raw material, is stewed to purslane juice after being fermented, and is mixed with generally fermented vinegar to prepare the purslane vinegar; the product contains no additive, such as artificially added acetic acid, food additive, pigment and the like; and health protection vinegar with ester fragrant, sour and sweet taste and specific purslane flavor and nutritional functions is prepared. The purslane vinegar is prepared by mixing the purslane juice with the existing vinegar, wherein the purslane juice is formed by stewing the fermented purslane; and the mixing ratio of the purslane juice to the vinegar is 1:15. The juice liquid of the product is clear, transparent and uniform, has no precipitate and suspended solids, and has mellow ester fragrant and proper sour and sweet taste; and the product is very popularized by consumers.

Owner:徐州绿之野生物食品有限公司

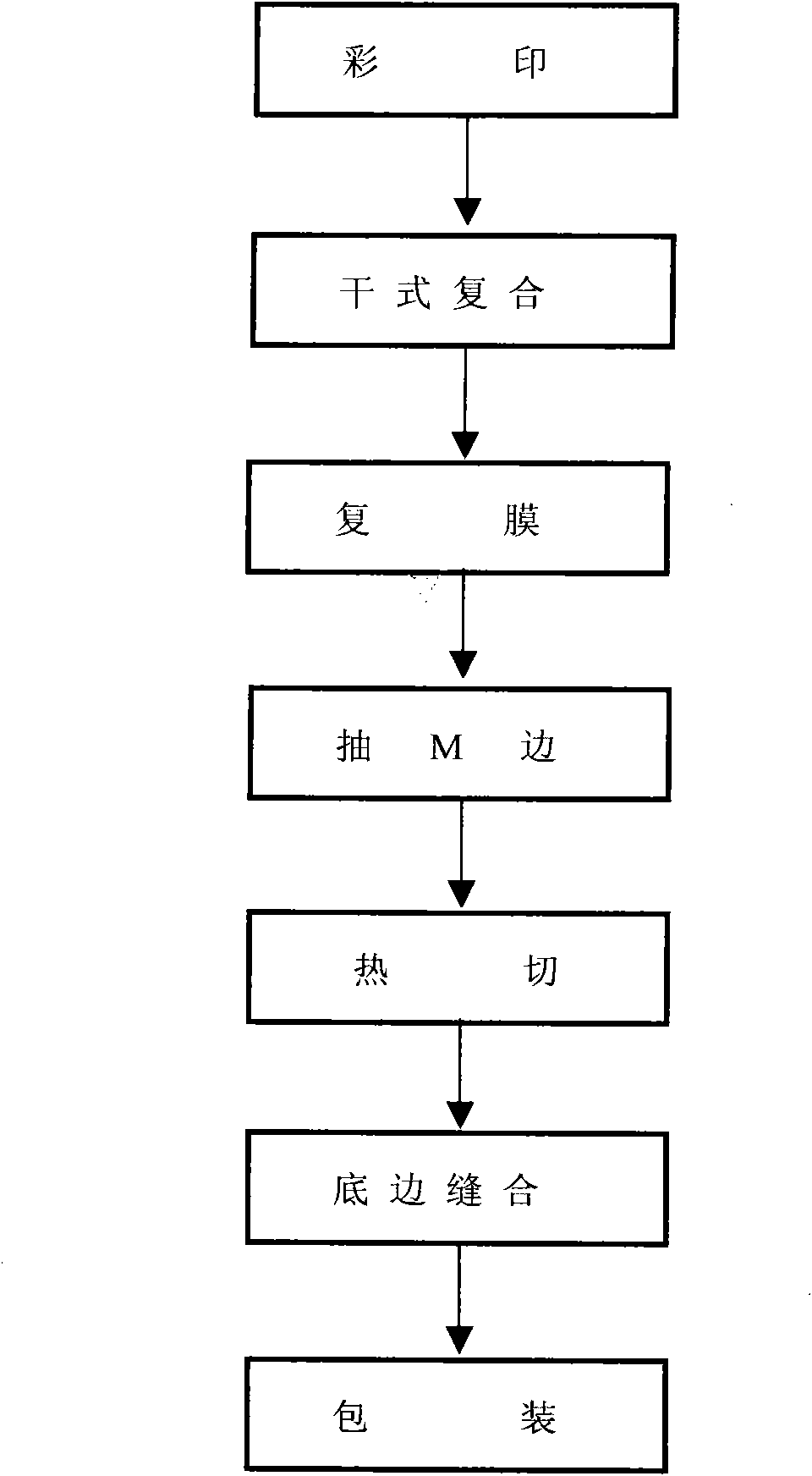

Antibacterial fresh-keeping packaging bag special for rice and processing method thereof

The invention relates to an antibacterial fresh-keeping packaging bag special for rice and a processing method thereof. At present, most of rice packages in China mainly adopt common plastic woven bags to package products, and in order to prevent rice leakage, the outer surfaces of the common plastic woven bags are coated with a coating layer of polyethylene or polypropylene materials. The plastic woven bags have no desinsection and sterilization performances and reduce the guarantee period of the rice. The invention provides a plastic woven bag and a coating layer membrane with vent holes coated on the outer surface, wherein the coating layer membrane material coated on the outer surface of the plastic woven bag consists of the master batch of a zinc oxide crystal whisker nano composite material and the master batch of a polyethylene (PE) or polypropylene (PP) material which are matched together, and the proportion of each component in percentage by weight is that the zinc oxide crystal whisker nano composite material accounts for 1 to 17 percent, and the polyethylene (PE) or the polypropylene (PP) material accounts for 83 to 99 percent. The plastic woven bag is used as the antibacterial fresh-keeping packaging bag special for the rice.

Owner:卢新宪

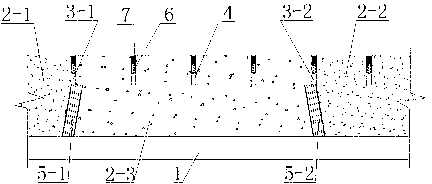

Cement concrete expansion joint structure with large area ground, and implementation method thereof

InactiveCN103233408AAvoid quality hazardsReduces the risk of thermal expansion extrusion failurePaving detailsBuilding material handlingExpansion jointCement

The invention discloses a cement concrete expansion joint structure with large area ground; the structure comprises a cushion layer (1), concrete plates (2-1, 2-2 and 2-3), main expansion joints (3-1 and 3-2) and a secondary expansion joint (4), wherein the main expansion joints (3-1 and 3-2) are arranged among the concrete plates (2-1, 2-2 and 2-3); the secondary expansion joint (4) is arranged on the concrete plate (2-3); a 'comb-teeth-shaped' cross section is formed by the concrete plate (2-3) and the secondary expansion joint (4); extruded plates (5-1 and 5-2), a flexible filler and a flexible sealing material are filled in the main expansion joints (3-1 and 3-2); and the flexible filler and the flexible sealing material are also filled in the secondary expansion joint (4). The cement concrete expansion joint structure effectively eliminates the destructive power of temperature effect for the ground concrete, and the set widths of the expansion joints are very narrow, so that the joint hole concrete exposed corners can be better protected, the quantity of the sealing material in the joints can be reduced, and good economical efficiency can be achieved.

Owner:李永奎

Data arrangement, method, dental-care-related device and software product for dental-care quality assurance

ActiveUS8452614B2Good quality assuranceEasy to processData processing applicationsSurgeryData systemSoftware product line

Owner:PLANMECA

Grain sterilizing bag and processing method

An antibacterial packing bag for grains is prepared through proportionally mixing zinc oxide crystal whisker with polyethene or polypropene, high-temp fusing, coating it on the surface of the braided plastic fabric, printing color pattern, punching to form air pinholes, cutting and sewing. Its advantage is high antimildew and antibacterial effect.

Owner:卢新宪

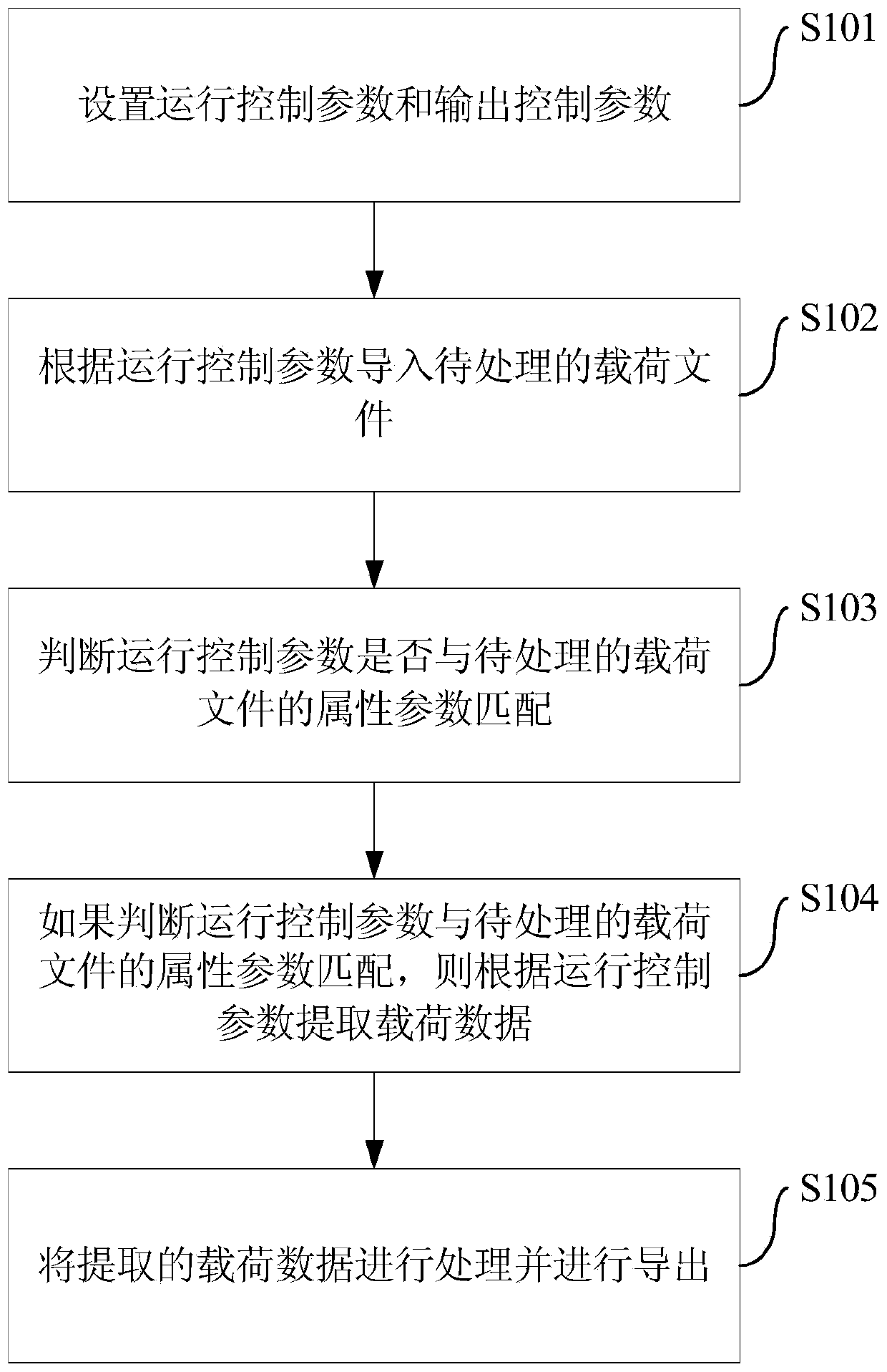

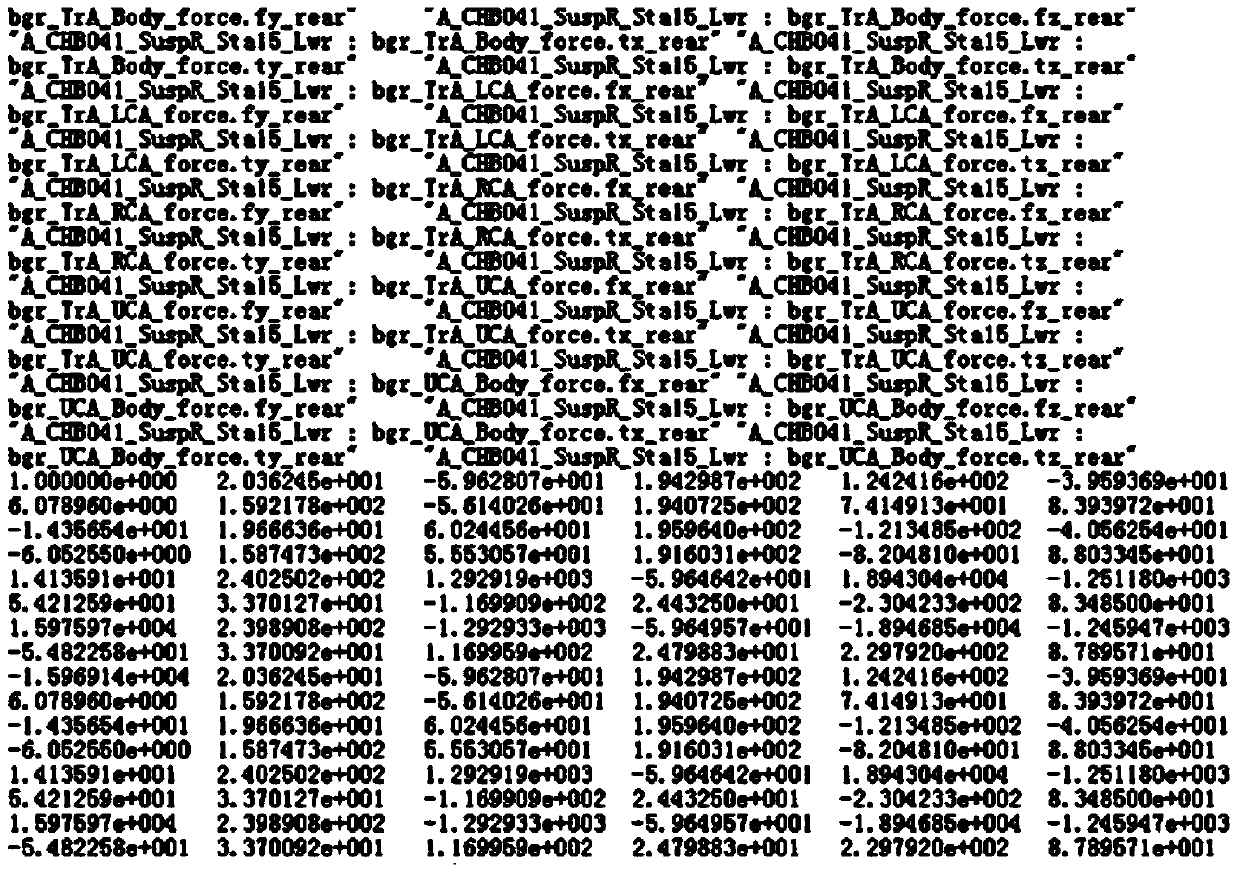

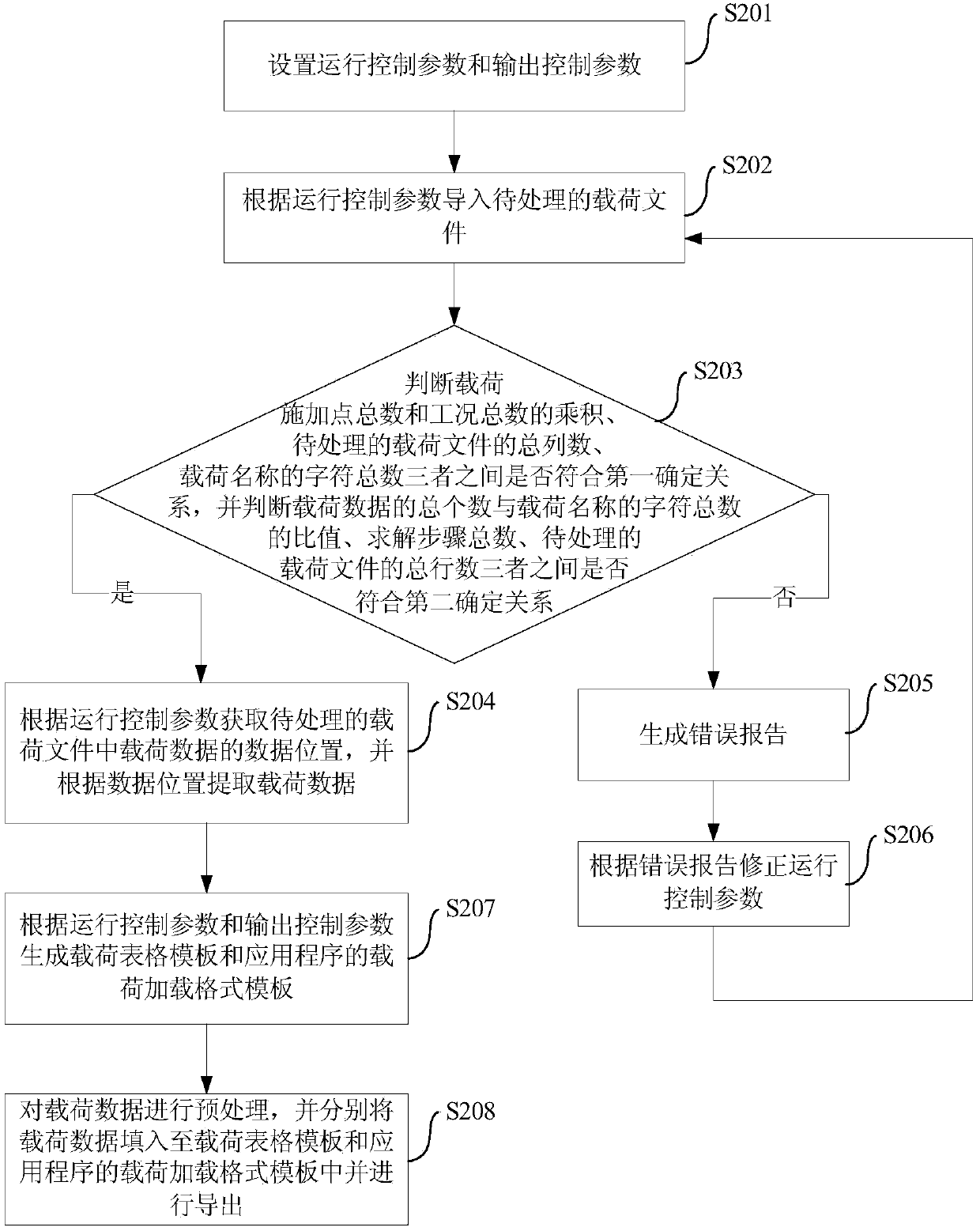

Load file processing method and device of vehicle

InactiveCN103559350AReduce work intensityAvoid subjective mistakesSpecial data processing applicationsQuality of workUltimate tensile strength

The invention provides a load file processing method and a load file processing device of a vehicle. The method comprises the steps of setting running control parameters and output control parameters; importing a to-be-processed load file according to the running control parameters; judging whether the running control parameters are matched with attribute parameters of the to-be-processed load file or not; if the running control parameters are judged to be matched with the attribute parameters of the to-be-processed load file, extracting load data according to the running control parameters; processing and exporting the extracted load data. By adopting the method disclosed by the embodiment of the invention, the working efficiency is improved, and the working intensity of workers is reduced; when errors occur, an error report is generated and is automatically modified and processed, so that the subjective fault of the workers is avoided, the working quality is improved, and further excellent quality guarantee is provided for the later-period vehicle performance design.

Owner:GREAT WALL MOTOR CO LTD

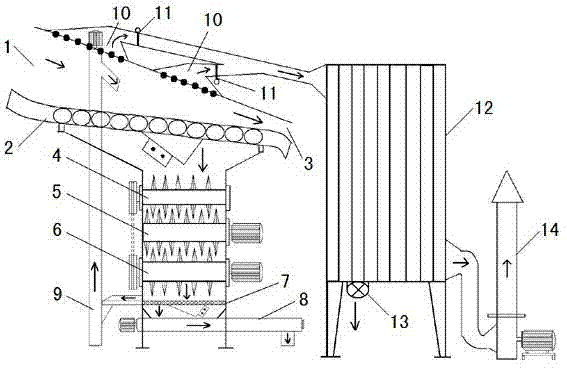

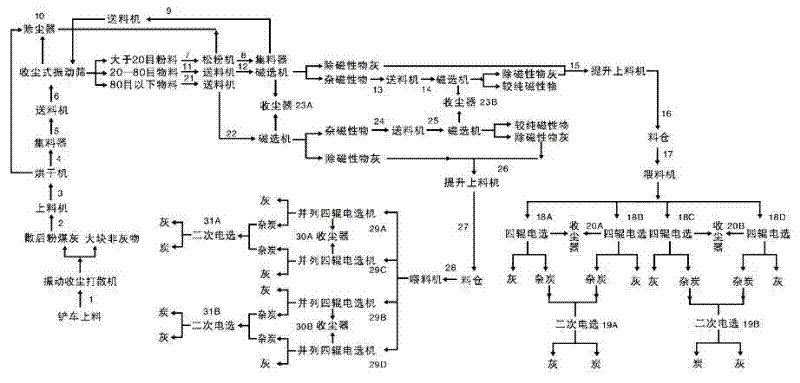

Method for extracting magnetic materials and carbon from pulverized coal ash

InactiveCN102442704AIncrease added valueImplement extractionSievingIron oxides/hydroxidesMagnetic separatorAdditional values

A method for extracting magnetic materials and coal from pulverized coal ash relates to the technical field of pulverized coal ash separation and sequentially comprises the steps of: separating an ash material into a big non-ash material block and scattered pulverized coal ash; drying the scattered pulverized coal ash and then sending the dried ash to a dust collecting type vibrating screen; sending materials which are bigger than a certain reference material to a material loosening machine and sending the materials back to the dust collecting type vibrating screen after the material loosening process; and sending materials which are not bigger than the certain reference material to a magnetic separator to be divided into magnetism-free material ash and miscellaneous magnetic materials, wherein the magnetism-free material ash is subjected to one electric separation, the product thereof is divided into miscellaneous coals and ash, and the miscellaneous coals are subjected to a second electric separation to form coal and ash; the miscellaneous magnetic materials are sent to the magnetic separator to be magnetically separated into magnetism-free material ash and relatively pure magnetic materials; the relatively pure magnetic materials are collected; and the magnetism-free material ash and the magnetism-free materials are combined for a treatment. The invention has the advantages that magnetic materials and coal can be extracted from the pulverized coal ash, various materials contained in the pulverized coal ash are used comprehensively and additional values of the pulverized coal ash are improved.

Owner:巨锋

Instant inoculation method

InactiveCN101508008AEvenly distributedShort stayMolten metal pouring equipmentsMetallurgyInoculation methods

The invention relates to an instantaneous inoculation method, which has good inoculation effect, improves the quality consistency of forged pieces, and can be used for producing wind power generation forged pieces with extremely high performance requirements and capable of resisting low-temperature shock to large-section ductile iron. The method adopts a runner cup to pour; molten iron is poured into a straight pouring channel at constant flow rate; and the method is characterized in that instantaneous inoculant is added into a sand box from the top of the sand box at a uniform speed at the same time of pouring and then enters the straight pouring channel in the sand box through a pipeline, and the instantaneous inoculant and the molten iron in a half filling state in the straight pouring channel are mixed and then poured into a die cavity.

Owner:辽宁隆达集团百星达铸造有限责任公司

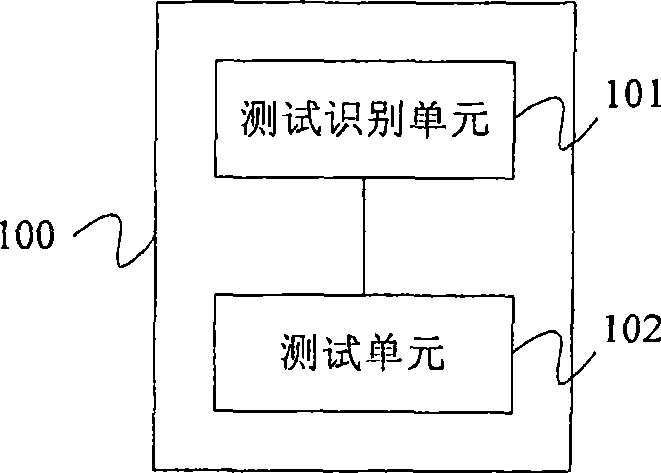

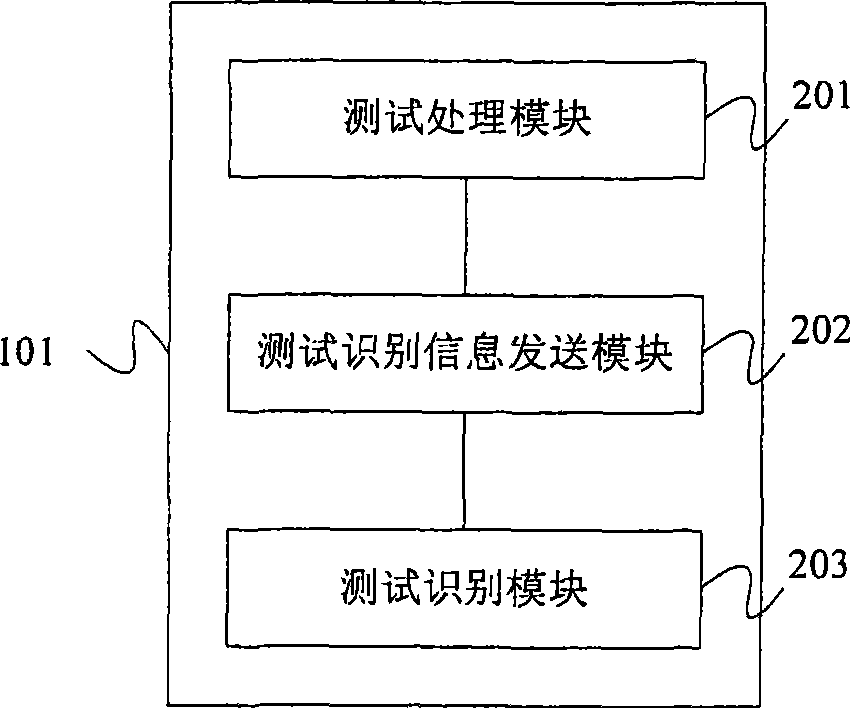

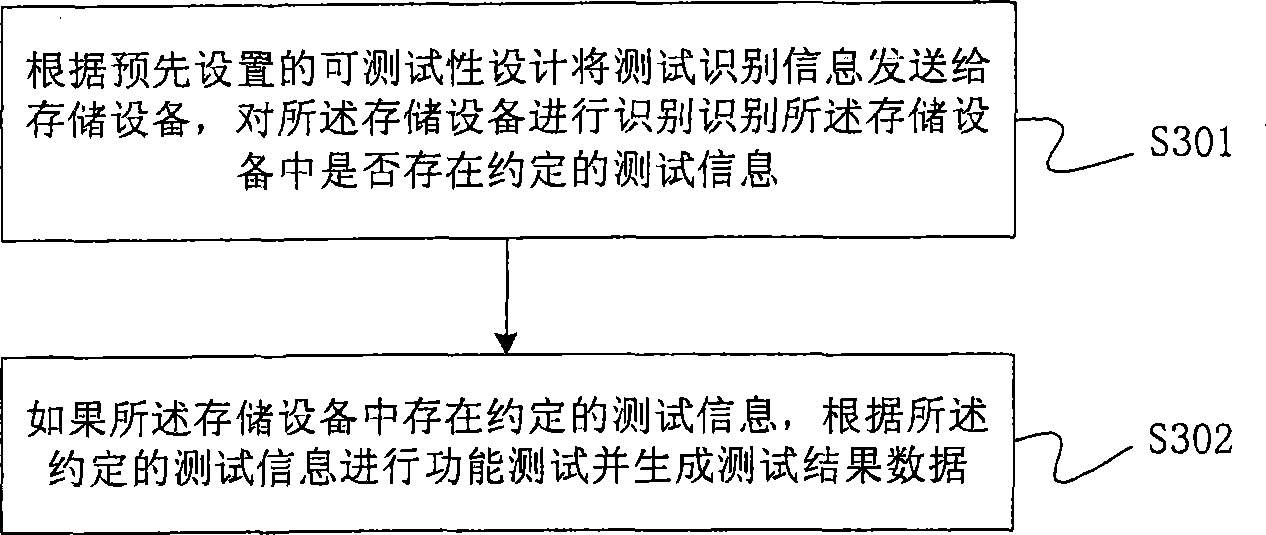

Functional test method, terminal device and system based on memory apparatus

ActiveCN101488984AReal-time communicationComprehensive functional coverageElectronic circuit testingSubstation equipmentDesign for testingFunctional testing

The invention provides a functional test method, terminal device and system based on storage device. The method comprises: sending test identifying information to the storage device according to predetermined design for testing, identifying whether there is promissory test information in the storage device; if so, processing functional test and generating test result data according to the promissory test information. The invention processes automated functional test for product by host computer interfaces of the storage device. A commissioning terminal can send test information to the storagedevice real-time to realize real-time communication of the commissioning terminal and the tested device. The invention is characterized in complete functional cover, good quality assurance, high testefficiency, low cost and convenient test operation.

Owner:HUAWEI DEVICE CO LTD

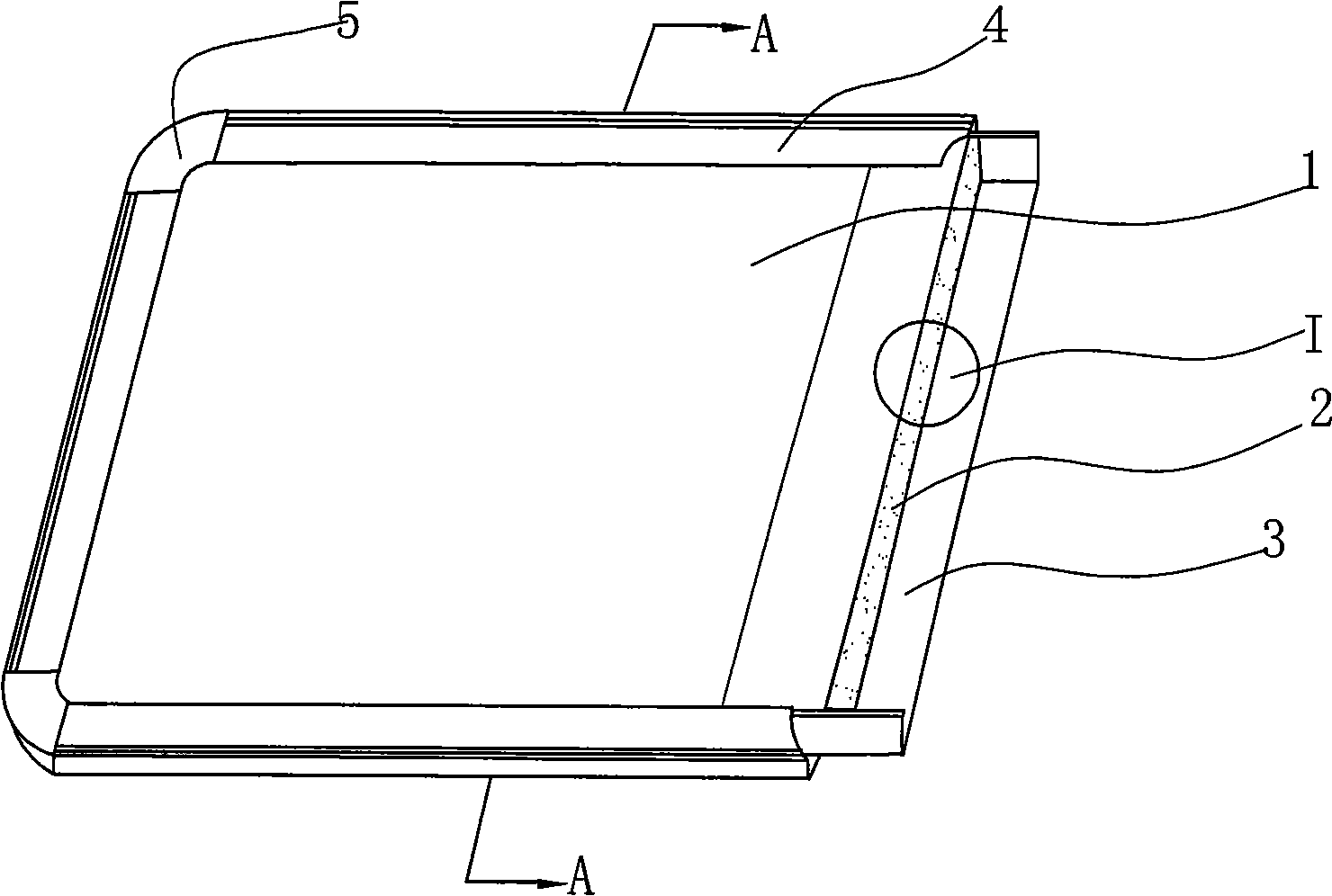

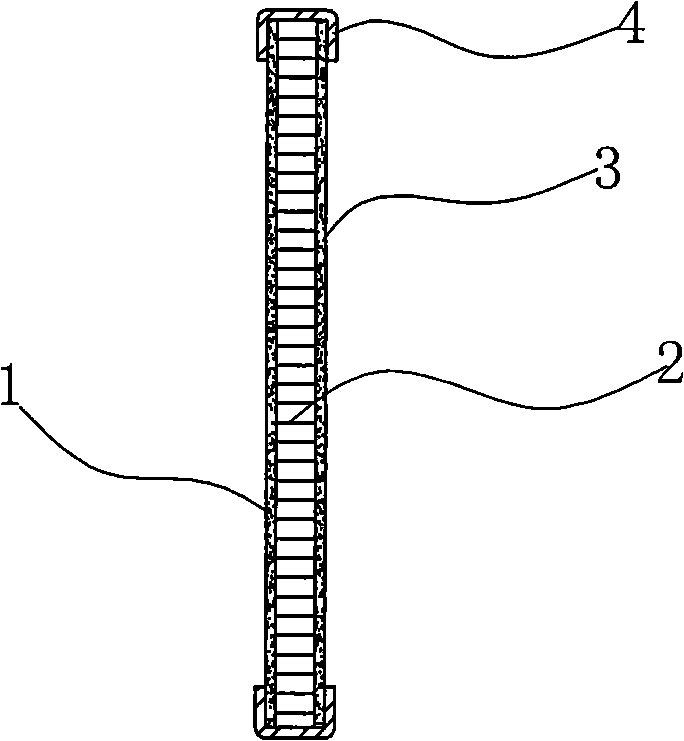

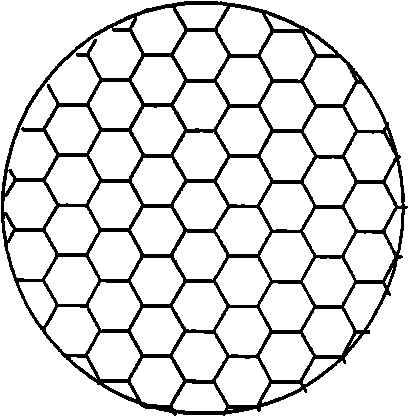

Application of honeycomb paper core or honeycomb paperboard in writing board

The invention relates to the application of a honeycomb paper core or a honeycomb cardboard in a writing board, which is characterized in that the honeycomb paper core or the honeycomb cardboard is used as a cardboard core of the writing board and is fixedly arranged between a panel and a base plate. The thickness of the honeycomb paper core or the honeycomb cardboard ranges from 5 to 50mm, and the weight is 110 to 180g / m<2>. The panel and the base plate adopt fiberboards, or zinked sheets, or plastic boards, or white boards, or cloth, the thickness ranges from 0.5 to 3mm, and the weight is 100 to 700g / m<2>. With the application, the writing board is great in strength, smoother, light in weight, and low in cost.

Owner:梁国宝

Method for improving hole sealing of blue gel ink of PCB board

InactiveCN107567189ANot easy to breakGood quality assuranceNon-metallic protective coating applicationScreen printingPunching

The invention relates to a method for improving hole sealing of blue gel ink of a PCB board. The method comprises the following steps of making a punching belt by reference to a position which needs screen printing of the blue gel ink on the surface of the PCB board; selecting a fiberboard and carrying out plate opening process by reference to the size of the PCB board; adopting the punching beltand punching an empty slot into the fiberboard; bonding the punched fiberboard and a mesh through an adhesive tape and glue and drying; mounting a screen on a screen printing table; blocking a throughhole whose aperture is greater than 3.0 mm at the back of the PCB board through a high temperature resistant adhesive tape; selecting an NPTH hole on the PCB board as a positioning hole and fixing onthe screen printing table through a locating pin; carrying out screen printing on the blue gel ink on the PCB board; drying the PCB board; and tearing the adhesive tape to complete. The blue gel inkin the through hole with the large aperture and the blue gel ink on the surface of the PCB board are integrated, when the blue gel ink is torn off, the rupture of the blue gel ink cannot occur and thehole has no residual blue glue ink, so that the production efficiency is greatly improved and the good quality guarantee is also provided for SMT.

Owner:惠东县建祥电子科技有限公司

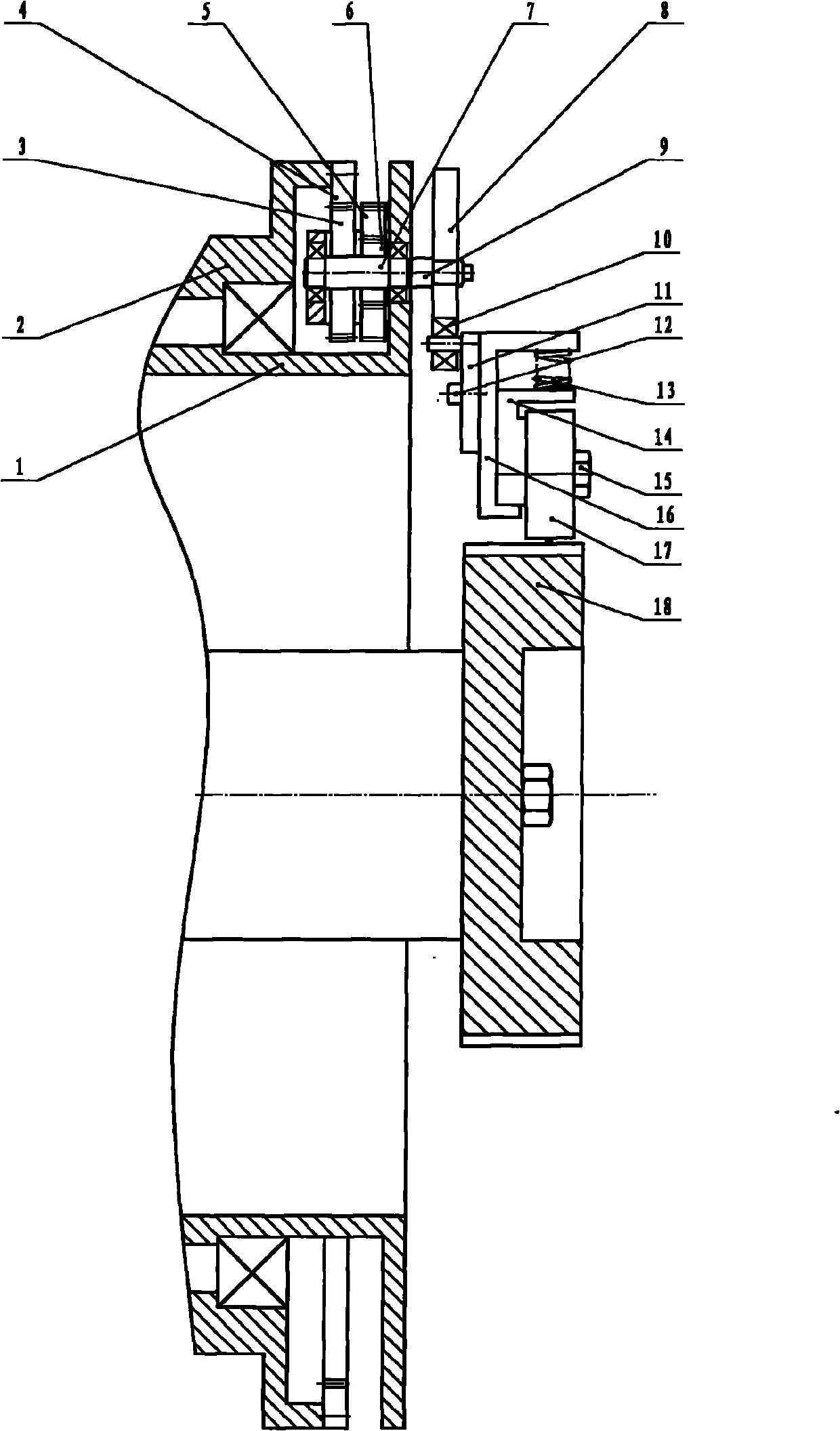

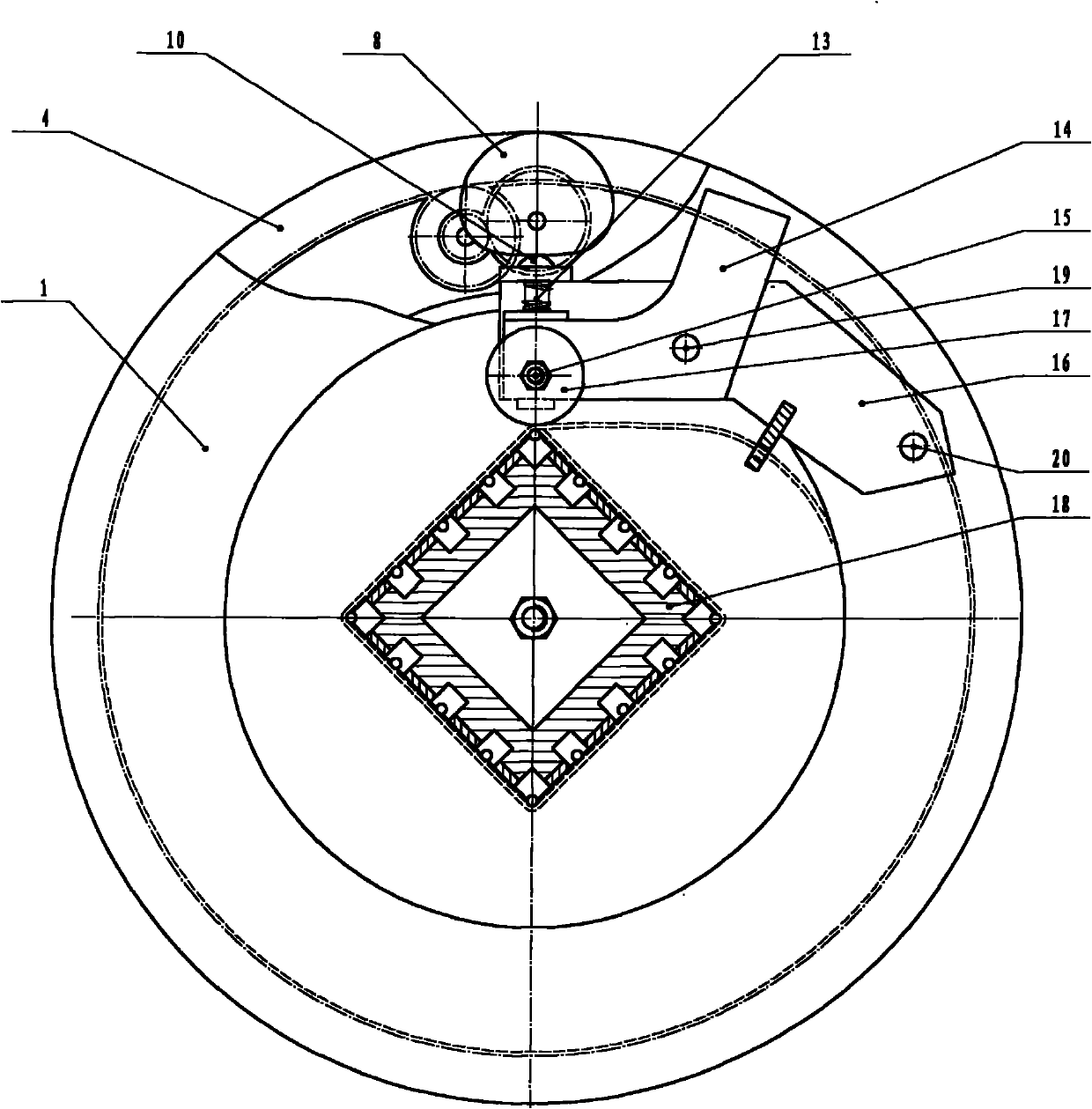

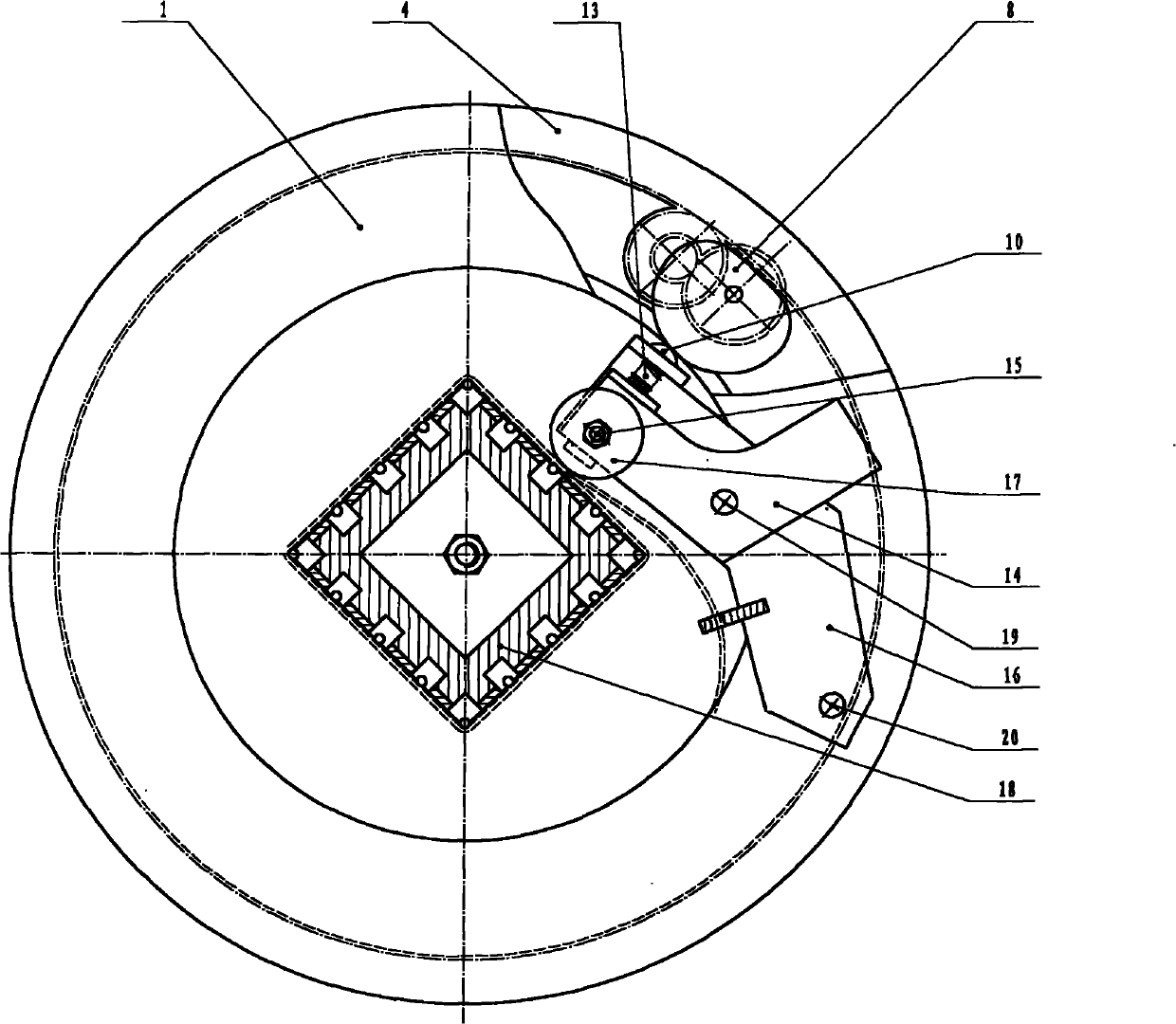

Welding and forming device of concrete hollow square pile reinforcing cage

The invention discloses a welding and forming device of a concrete hollow square pile reinforcing cage, which comprises an electrode profile modeling, an electrode welding arm, an electrode wheel assembly, a cam, a gear driving mechanism and the like, wherein the electrode welding arm is arranged on a main machine turnplate and can swing around a fixed point of the main machine turnplate; the electrode assembly is arranged on a rotating shaft of the electrode welding arm; the cam is arranged on the main machine turnplate; when a main machine rotates, the cam is driven by an inner gear driving mechanism to rotate; the cam is used as a profiling element of the motion track of an electrode wheel; the electrode profile modeling (an insulated material covered at a non-work part) is fixed on an engine seat of the main machine; the electrode profile modeling, the electrode wheel and the cam are in a non-radial mechanical connection; the motion track of the electrode wheel is limited between the cam and the electrode profile modeling; and the electrode wheel can accurately coincide with all points of the electrode profile modeling. The invention thoroughly solves the difficult problems of the welding and the forming of the square pile reinforcing cage distributed by any longitudinal ribs. The device has the remarkable characteristics of novelty, simpleness, reliability, stable welding quality and small loss of welding point strength.

Owner:汪泽民 +2

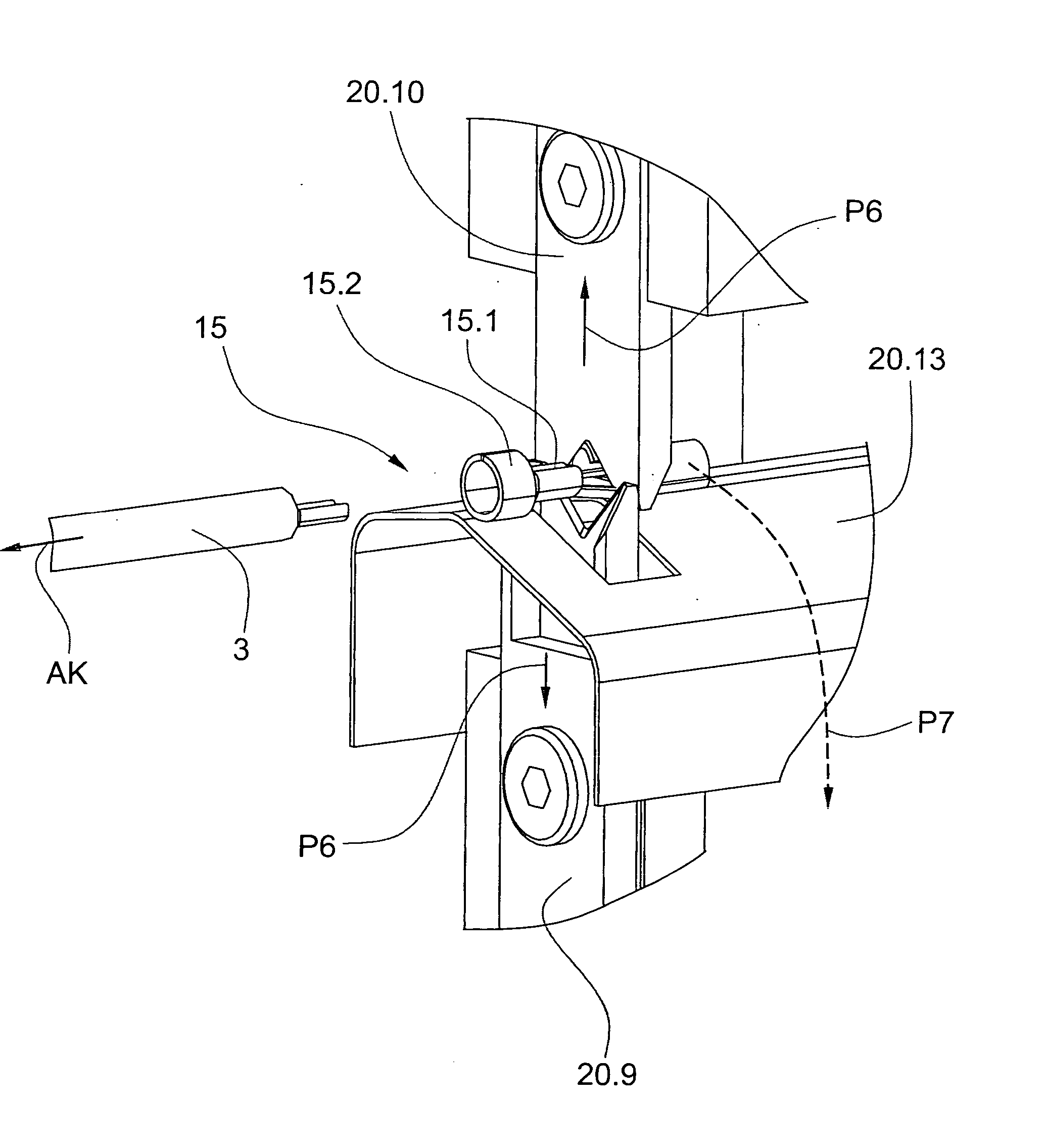

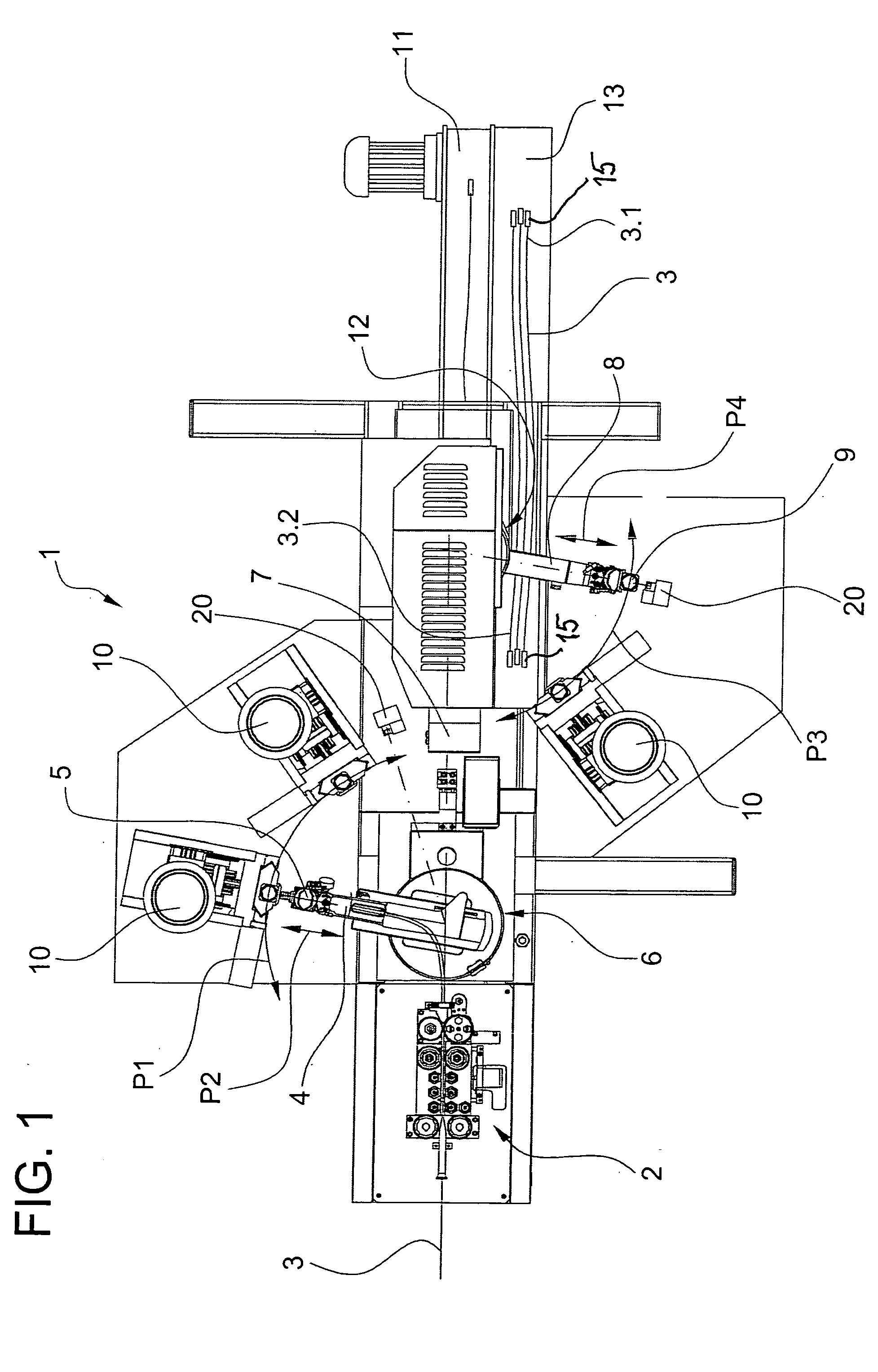

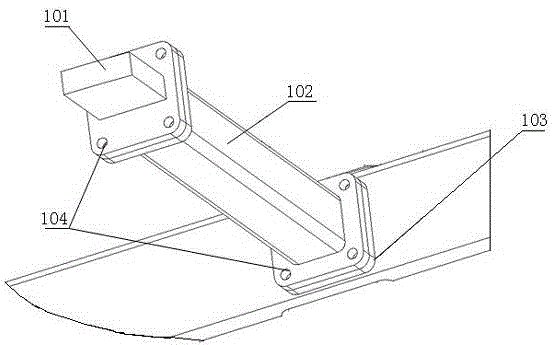

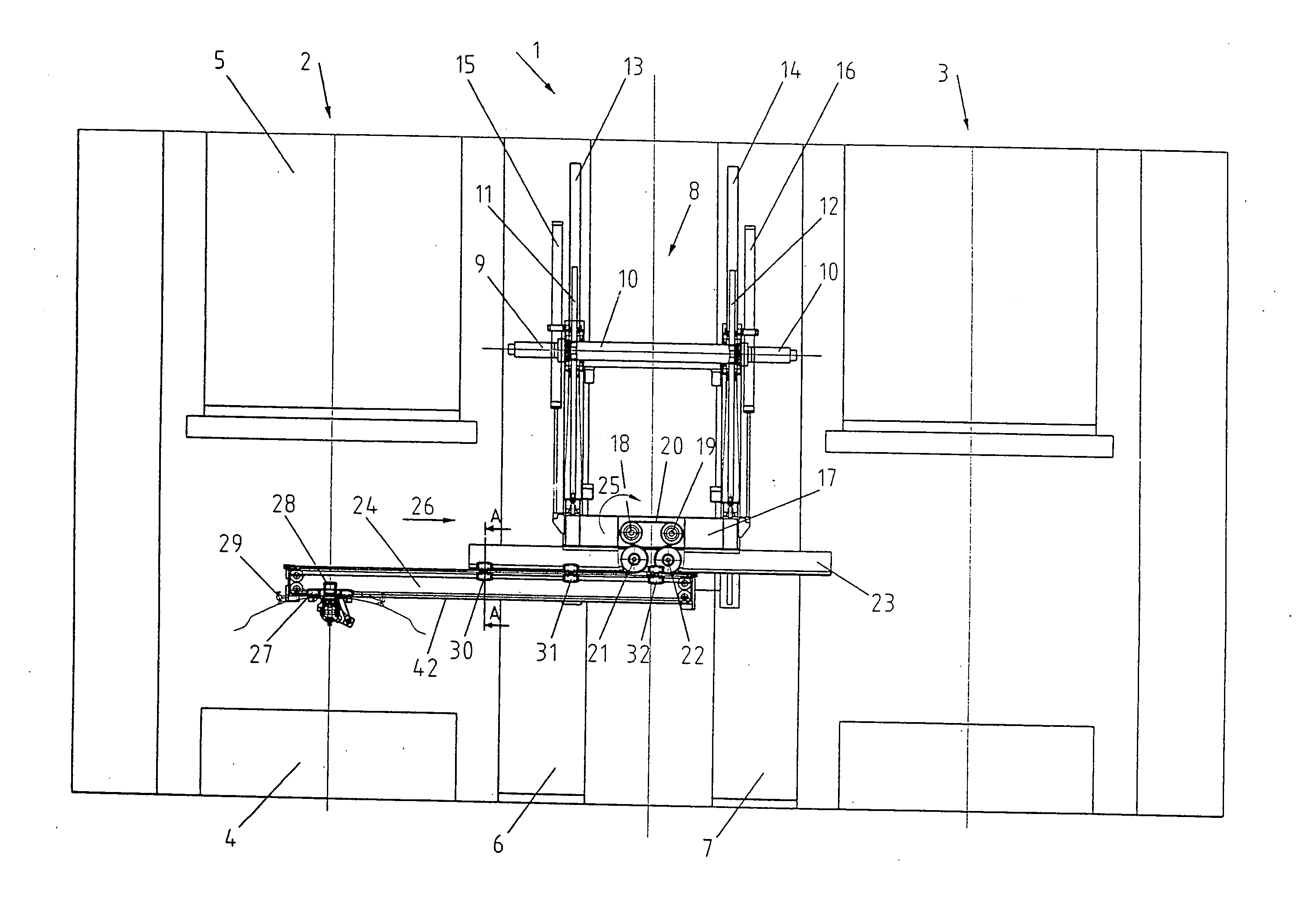

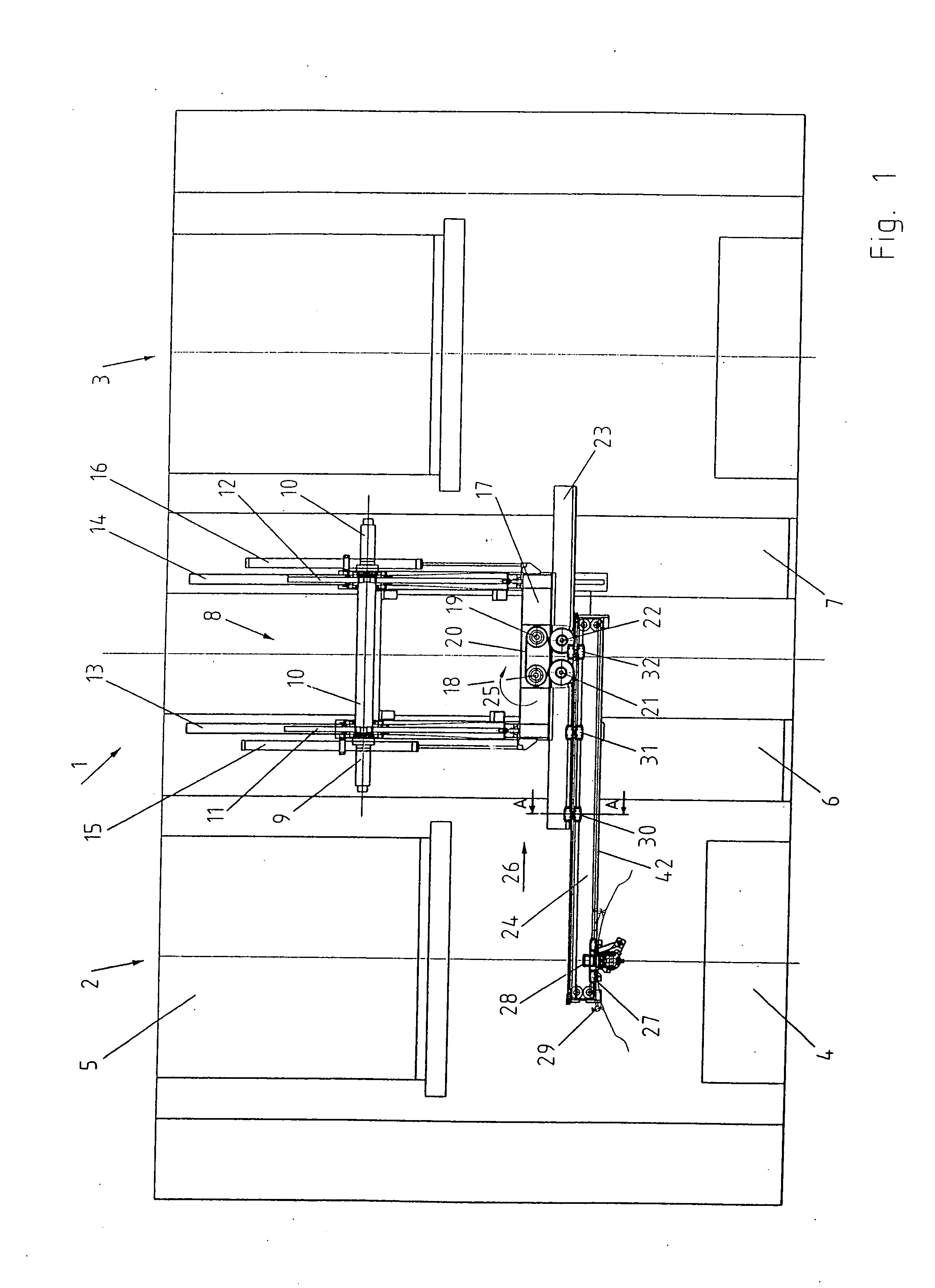

Conveying device

InactiveUS20090078532A1Improve qualityGood quality assuranceMetal-working feeding devicesControl devices for conveyorsTransfer moldingCantilever

Disclosed is a device for conveying workpieces through a press working line or a transfer molding press. The conveying device is embodied as a telescopic feeder and is designed such that a jib which can be displaced in a longitudinal direction is mounted or guided by means of guiding carriages that travel along. An adequate entraining mechanism is provided in order to ensure the traveling motion of the guiding carriages.

Owner:MASCHFAB MULLER WEINGARTEN AG

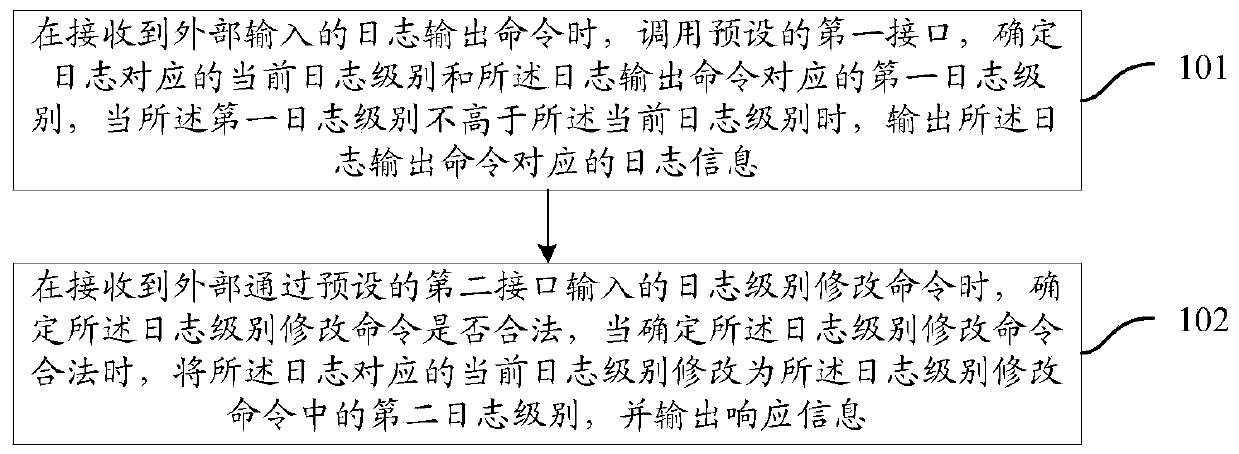

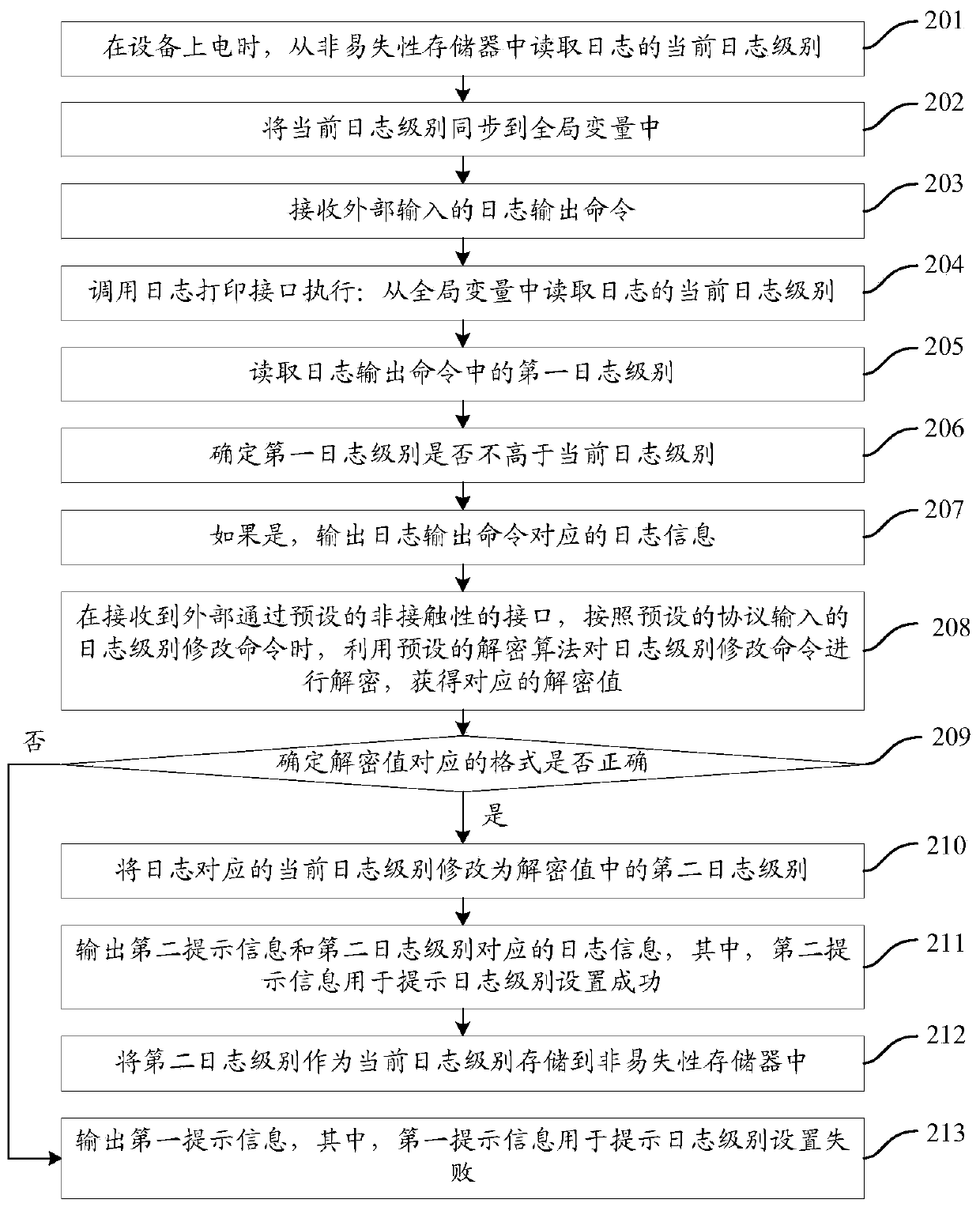

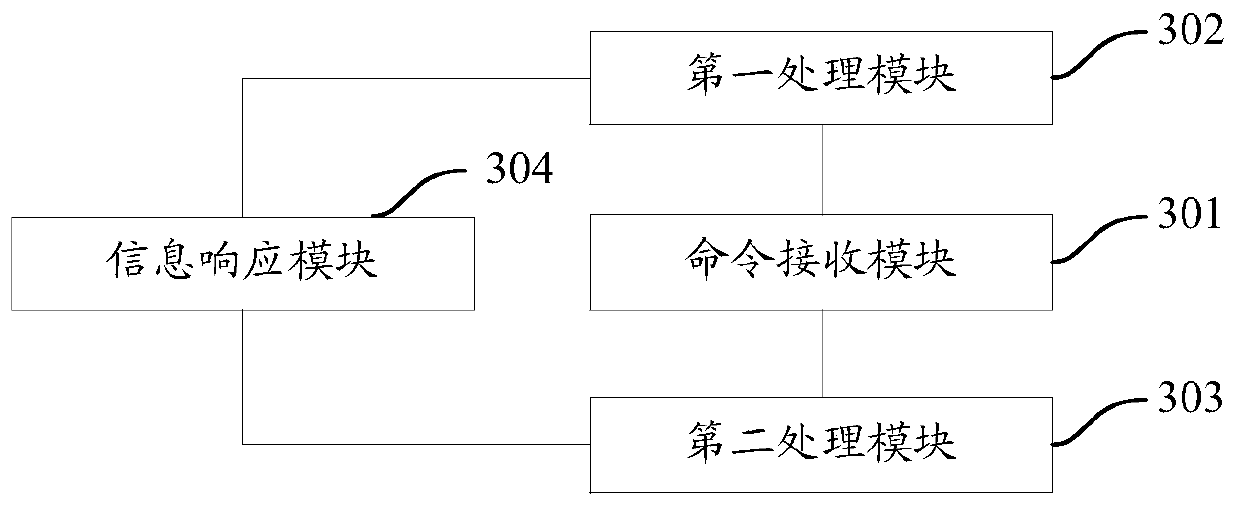

Method and device for dynamically configuring logs

PendingCN110007956AImprove securityReduce management difficultyProgram documentationReal-time computing

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com