Low-temperature, heat-sealing and inflation-resistant CPP aluminum-plated film and preparation method thereof

A low-temperature heat-sealing and aluminized film technology, applied in chemical instruments and methods, flexible coverings, packaging, etc., can solve the problems of poor toughness, heat-sealing strength (weak barrier property, etc.), and achieve improved production efficiency and long-term quality The effect of guaranteeing and improving the speed of the aircraft package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

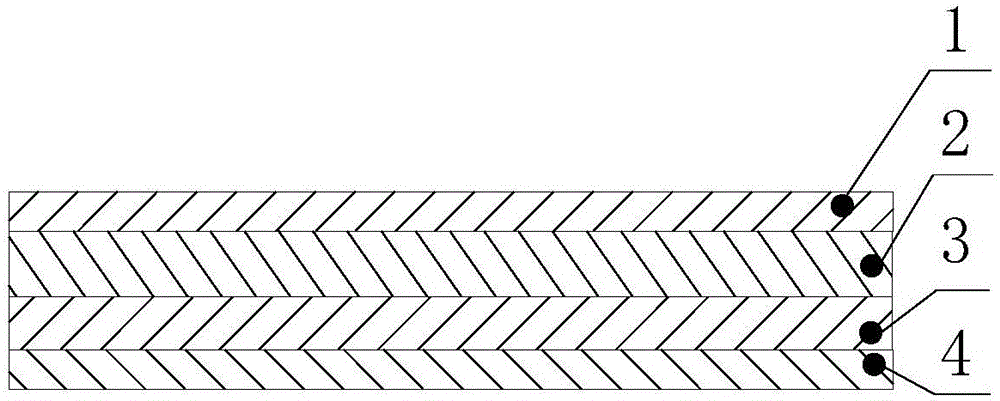

[0029] Such as figure 1 As shown, a low-temperature heat-sealable air-resistant CPP aluminized film is formed by four-layer co-extrusion of a heat-sealed layer, a first core layer, a second core layer, and an aluminized layer; the heat-sealed layer, the first core layer, the second core layer, and the aluminum plating layer are respectively: 19%, 29%, 34%, and 18%;

[0030] The material of the heat-sealing layer is formed by mixing ternary random copolymerized polypropylene (PP) resin, ethylene-vinyl acetate copolymer (EVA) and a modifier, and the mass percentages of each raw material are respectively: Standard copolymer polypropylene (PP) resin 40%, ethylene-vinyl acetate copolymer (EVA) 40%, modifier 20%;

[0031] The material of the first core layer is formed by mixing polypropylene resin and metallocene polyethylene (linear), and the mass percentages of each raw material are: polypropylene resin 65%, metallocene polyethylene 35%;

[0032] The material of the second core ...

Embodiment 2

[0047] Such as figure 1 As shown, a low-temperature heat-sealable air-resistant CPP aluminized film is formed by four-layer co-extrusion of a heat-sealed layer, a first core layer, a second core layer, and an aluminized layer; the heat-sealed layer, the first core layer, the second core layer, and the aluminum plating layer account for the mass percentages of 20%, 28%, 34%, and 18% respectively;

[0048] The material of the heat-sealing layer is formed by mixing ternary random copolymerized polypropylene (PP) resin, ethylene-vinyl acetate copolymer (EVA) and a modifier, and the mass percentages of each raw material are respectively: Regular copolymerized polypropylene (PP) resin 45%, ethylene-vinyl acetate copolymer (EVA) 45%, modifier 10%;

[0049] The material of the first core layer is formed by mixing polypropylene resin and metallocene polyethylene (linear), and the mass percentages of each raw material are: polypropylene resin 70%, metallocene polyethylene 30%;

[0050...

Embodiment 3

[0065] Such as figure 1 As shown, a low-temperature heat-sealable air-resistant CPP aluminized film is formed by four-layer co-extrusion of a heat-sealed layer, a first core layer, a second core layer, and an aluminized layer; the heat-sealed Layer, the first core layer, the second core layer, and the aluminum plating layer account for the mass percentages: 20%, 29%, 33%, and 18% respectively;

[0066] The material of the heat-sealing layer is formed by mixing ternary random copolymerized polypropylene (PP) resin, ethylene-vinyl acetate copolymer (EVA) and a modifier, and the mass percentages of each raw material are respectively: Regular copolymerized polypropylene (PP) resin 50%, ethylene-vinyl acetate copolymer (EVA) 40%, modifier 10%;

[0067] The material of the first core layer is formed by mixing polypropylene resin and metallocene polyethylene (linear), and the mass percentages of each raw material are: polypropylene resin 75%, metallocene polyethylene 25%;

[0068] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com