Toughened cooking film and preparation method thereof

A cooking film and toughening technology, applied in chemical instruments and methods, other household utensils, packaging, etc., can solve the problem that the cooking film cannot meet market demand, achieve excellent fresh-keeping effect, good flexibility, and increase the speed of machine packaging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

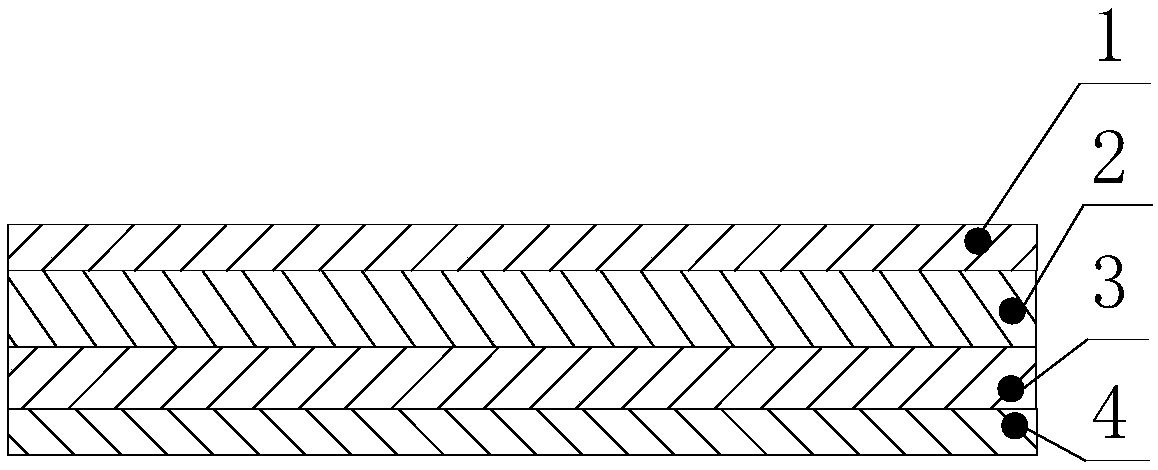

[0025] Such as figure 1 As shown, the present invention provides a toughened retort film, which is composed of a heat-sealing layer 1, a core layer 2, a toughening layer 3, and a corona layer 4, which are sequentially stacked and cast four-layer co-extrusion; The mass percentages of sealing layer, core layer, toughening layer and corona layer are respectively: 18%, 27%, 37%, 18%;

[0026] The material of the heat-sealing layer is formed by mixing ternary random copolymerized polypropylene (PP) resin, ethylene-vinyl acetate copolymer (EVA) and modified masterbatch, each raw material accounts for the mass percentage of the heat-sealing layer They are: ternary random copolymerization polypropylene (PP) resin 50%, ethylene-vinyl acetate copolymer (EVA) 40%, modified masterbatch 10%,;

[0027] The material of the core layer is formed by mixing wire-drawing grade polypropylene resin, ethylene-propylene elastomer and metallocene polyethylene (linear), and the mass percentages of eac...

Embodiment 2

[0036] Such as figure 1 As shown, the present invention provides a toughened retort film, which is composed of a heat-sealing layer 1, a core layer 2, a toughening layer 3, and a corona layer. The mass percentages of heat-sealing layer, core layer, toughening layer and corona layer are respectively: 17%, 27%, 38%, 18%;

[0037] The material of the heat-sealing layer is formed by mixing ternary random copolymerized polypropylene (PP) resin, ethylene-vinyl acetate copolymer (EVA) and modified masterbatch, each raw material accounts for the mass percentage of the heat-sealing layer They are: ternary random copolymerization polypropylene (PP) resin 40%, ethylene-vinyl acetate copolymer (EVA) 40%, modified masterbatch 20%,;

[0038] The material of the core layer is formed by mixing wire-drawing grade polypropylene resin, ethylene-propylene elastomer and metallocene polyethylene (linear), and the mass percentages of each raw material in the core layer are: wire-drawing grade polyp...

Embodiment 3

[0050] Such as figure 1 As shown, the present invention provides a toughened retort film, which is composed of a heat-sealing layer 1, a core layer 2, a toughening layer 3, and a corona layer. The mass percentages of heat-sealing layer, core layer, toughening layer and corona layer are respectively: 18%, 26%, 38%, 18%;

[0051] The material of the heat-sealing layer is formed by mixing ternary random copolymerized polypropylene (PP) resin, ethylene-vinyl acetate copolymer (EVA) and modified masterbatch, each raw material accounts for the mass percentage of the heat-sealing layer They are: ternary random copolymerization polypropylene (PP) resin 40%, ethylene-vinyl acetate copolymer (EVA) 50%, modified masterbatch 10%,;

[0052] The material of the core layer is formed by mixing wire-drawing grade polypropylene resin, ethylene-propylene elastomer and metallocene polyethylene (linear), and the mass percentages of each raw material in the core layer are: wire-drawing grade polyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com