Method for extracting magnetic materials and carbon from pulverized coal ash

A technology for magnetic materials and fly ash, applied in chemical instruments and methods, waste fuel, titanium oxide/hydroxide, etc., can solve the problems of reduced active components of fly ash, waste of energy, poor stability, etc. Selecting efficiency and purity, reducing dust pollution, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

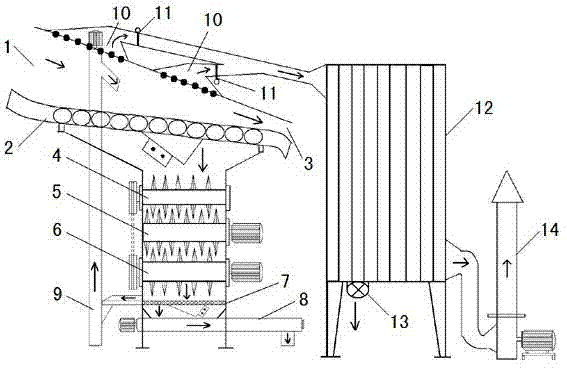

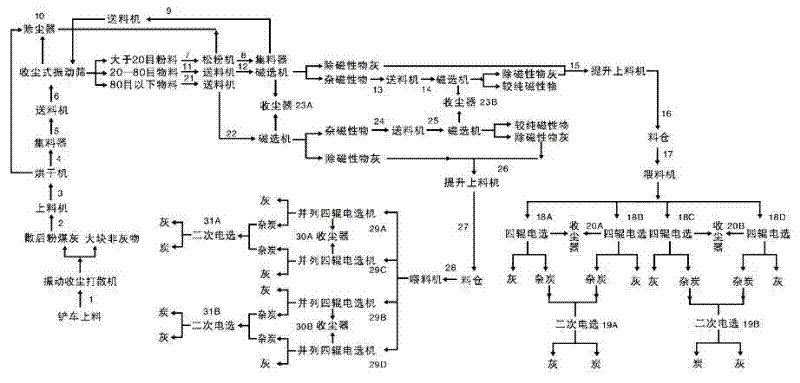

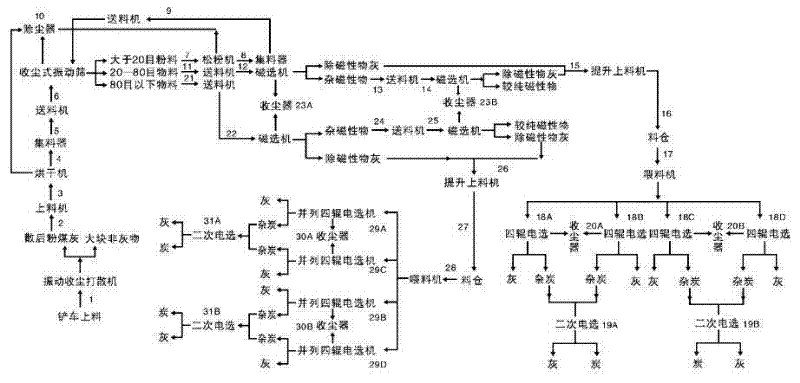

[0058] Such as figure 1 As shown, the fly ash material is fed to the vibrating dust collection type disintegrator 1 by a forklift or other machinery, and the machine 1 separates the fly ash material into large pieces of non-ash and dispersed fly ash, large A piece of non-ash matter is placed to be processed; after being dispersed, the fly ash is led to the dryer 3 through the feeder 2, and during the drying process of the dryer 3, light matter (lighter matter is produced with dust) gases) and heavy substances (heavier substances) are treated separately; among them,

[0059] The light matter is led to the dust collector 10 to be discharged after dust removal treatment;

[0060] The heavy objects are introduced into the collector 4 and sent to the dust-collecting vibrating screen 6 through the feeder 5. During the working process of the dust-collecting vibrating screen 6, the vibrating screen produces light and heavy objects during the working process. Among them,

[0061] Th...

Embodiment 2

[0086] This embodiment 1 is a simplification of embodiment 2, wherein the materials described in embodiment 1 are less than or equal to 20 mesh, greater than or equal to 80 mesh materials, and less than 80 mesh materials; combined into less than or equal to 20 mesh materials, according to Materials less than or equal to 20 mesh and greater than or equal to 80 mesh are processed (different types of fly ash are screened and classified with different particle sizes).

[0087] The structure of the vibrating dust collecting formula breaker described in the present embodiment 1 is as follows:

[0088] Such as figure 2 As shown, the vibrating dust collection type dispersing machine is mainly suitable for various powder materials or granular materials that are agglomerated due to moisture, and need to be broken up and loosened to remove large debris.

[0089] There is a feeding port 1 on the upper part of the frame, which is used to use some kind of feeding equipment to feed the mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com