Antibacterial fresh-keeping packaging bag special for rice and processing method thereof

A packaging bag and rice technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of not being able to inhibit the growth and elimination of grain molds, unfavorable grain preservation, complicated production process, etc., and achieve the benefit of grain quality assurance , the formula is simple and novel, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The special antibacterial and fresh-keeping packaging bag for rice comprises: a plastic woven bag body and a coating film with ventilation holes on its outer surface, and the coating film material coated on the outer surface of the plastic woven bag is made of Zinc oxide whisker nanocomposite material masterbatch and polyethylene (PE) or polypropylene (PP) material masterbatch are combined, and the proportion of each component by weight is: zinc oxide whisker nanocomposite material 1-17%, polyethylene (PE) or polypropylene (PP) material 83-99%.

Embodiment 2

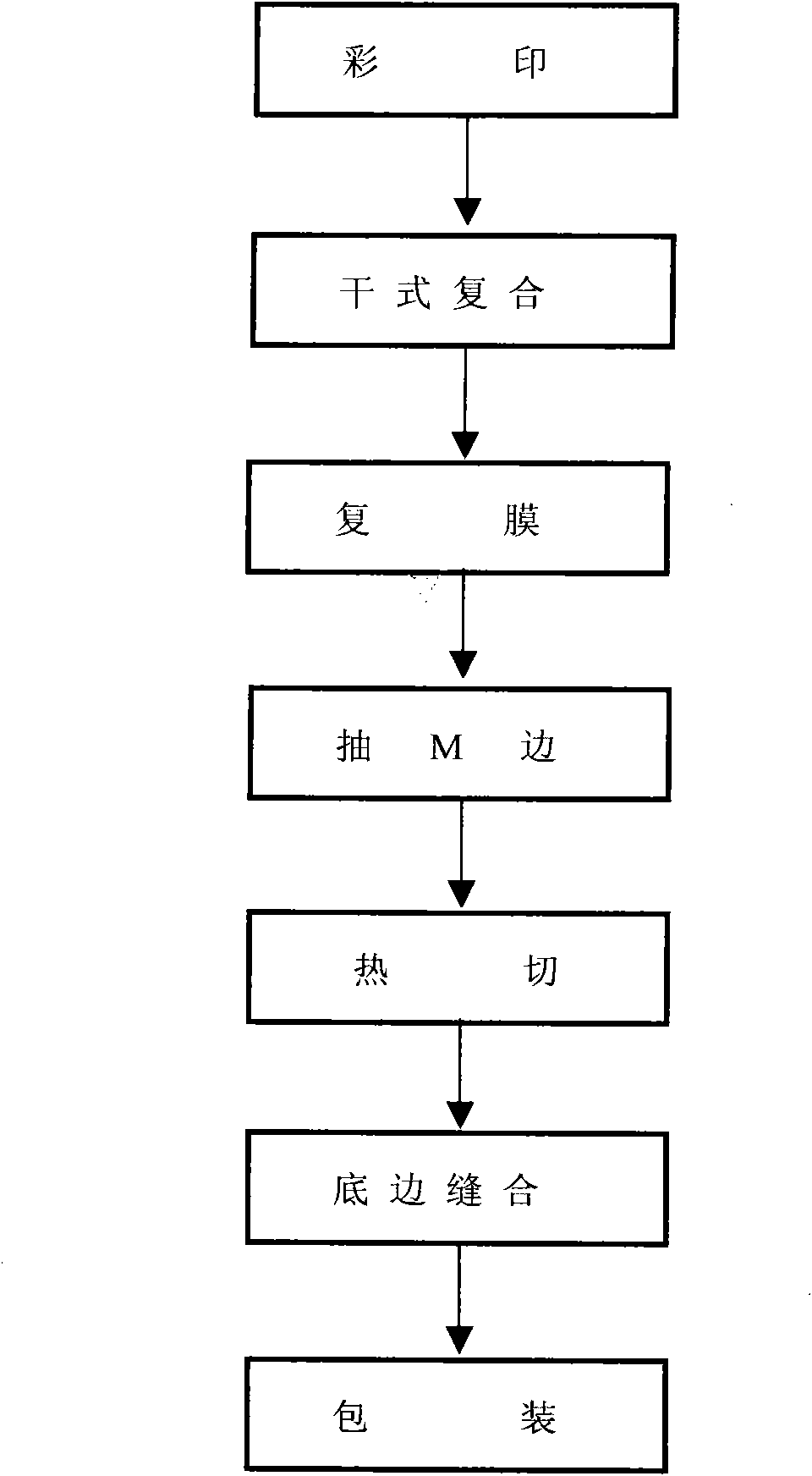

[0015] A kind of processing method of special antibacterial and fresh-keeping packing bag of rice, according to above-mentioned ratio weight, will all be powdery zinc oxide whisker nano-composite material masterbatch and polyethylene (PE) or polypropylene (PP) material masterbatch are mixed Evenly, melt the above-mentioned masterbatch mixture into a liquid state at a high temperature of 210-250°C, then drool-coat it on the surface of the plastic woven cloth to form a coating film, and color-print the desired pattern on the coating film of the plastic woven cloth. Make micro-shaped ventilation holes on the coating film and pattern, cut and sew the plastic woven cloth into grain antibacterial packaging bags.

Embodiment 3

[0017] The coating film material coated on the outer surface of the plastic woven bag includes 3% zinc oxide whisker nanocomposite material masterbatch and 97% polyethylene (PE) or polypropylene (PP) material masterbatch, Weigh it for later use; mix all the powdered zinc oxide whisker nanocomposite masterbatches with polyethylene or polypropylene material masterbatches, and mix them evenly in a mixer; send the evenly mixed materials into the coating machine, It melts into a liquid state at a high temperature of 210-250 ° C; the liquid mixed material is cast on the surface of the plastic woven cloth through the die head of the screw extruder to form a film layer; the color printing machine prints the color packaging pattern of the packaging bag on the On the coating layer; the punching machine punches micro-shaped ventilation holes on the coating layer; the plastic woven cloth is cut and sewn into finished grain packaging bags by cutting and sewing equipment.

[0018] The speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com