Instant inoculation method

A technology of instantaneous inoculation and sprue, which is applied in the control of pouring molten metal from the ladle, manufacturing tools, metal processing equipment, etc. Achieve the effect of improving quality consistency, improving quality stability, and realizing automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

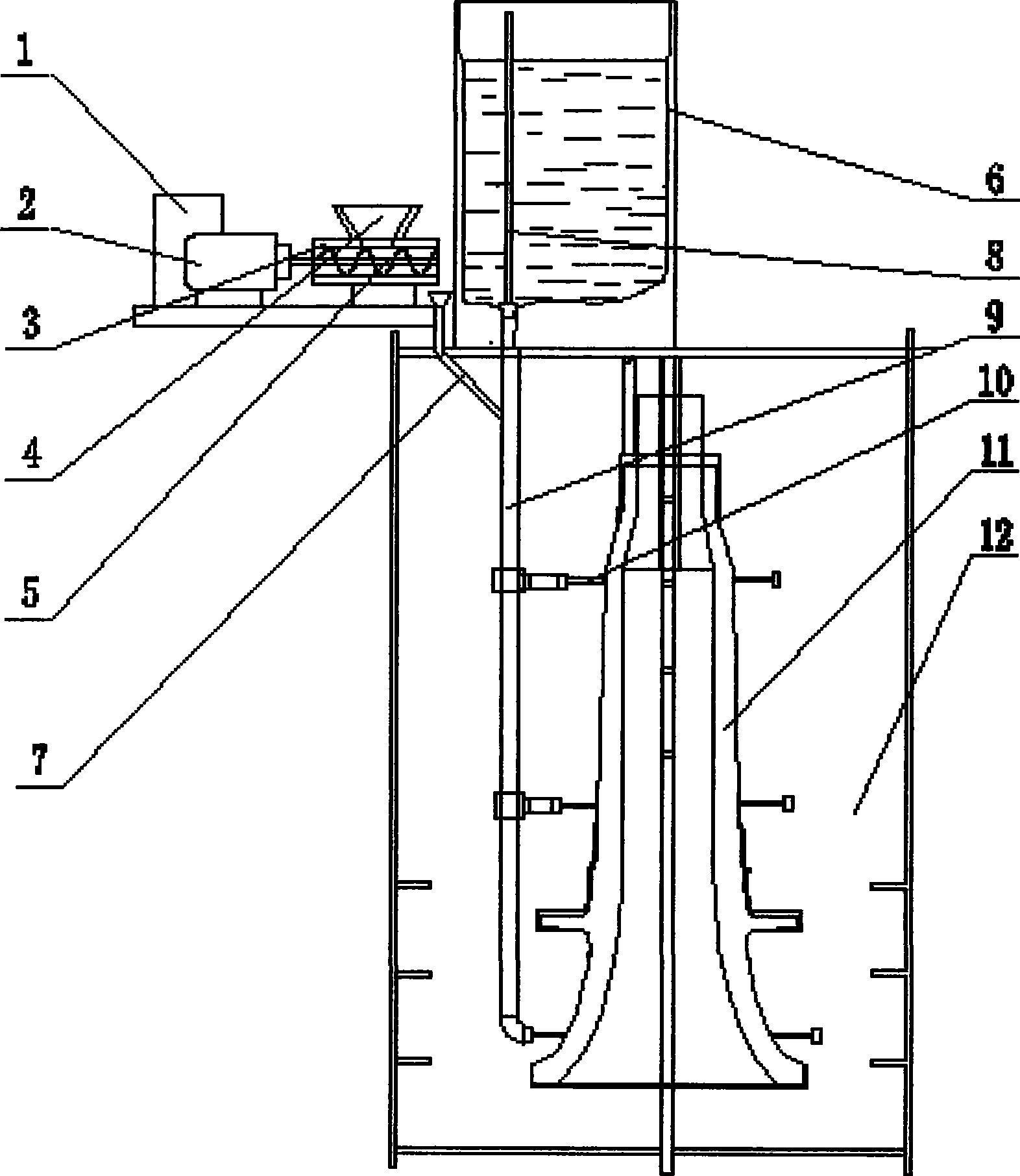

[0017] Embodiment: Taking the stator main shaft of a wind turbine as an example, the instantaneous inoculation method is described.

[0018] 1. Calculation of pouring time: the pouring weight is 6030Kg, and the process yield is designed to be 88%, so the pouring molten iron weight is 6700Kg. The pouring time is: t=(2 / 3)×SG 1 / 2 In the formula, S is the wall thickness coefficient, and for this casting, take 1.9; G is the pouring weight. This results in a pouring time: t=104 seconds.

[0019] 2. The amount and method of adding the instant inoculant

[0020] The amount of the instantaneous inoculant added is 0.2% of the amount of molten iron, and the running time of the motor 2 is the same as the pouring time, which is 104 seconds. It can be concluded that the adding speed of the instantaneous inoculant is: 130±2g / s. Use the quantitative feeding device 5 to add the instantaneous inoculant. In order to realize the quantitative addition, adjust the output power of the frequency c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com