Insulating and heat-conducting polymer composite with frequency-selective electromagnetic shielding and preparation method thereof

A frequency-selective, insulating and heat-conducting technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. Excellent electromagnetic shielding performance and thermal conductivity, the effect of excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

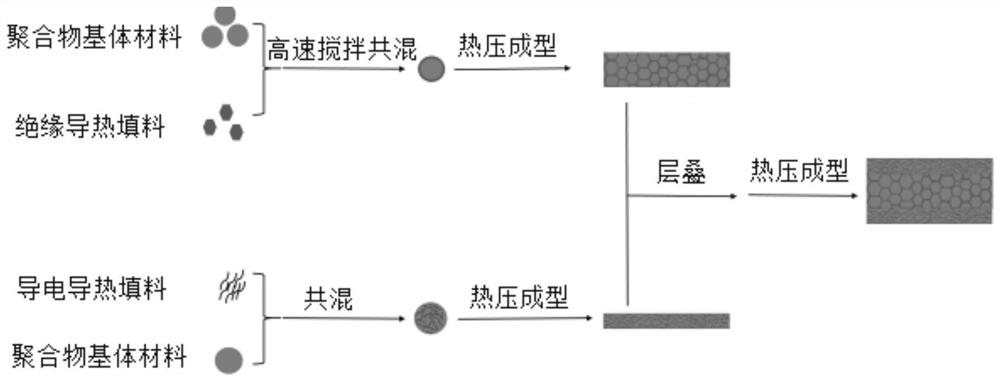

[0041] In this example, an insulating and thermally conductive polyurethane composite material with frequency selective electromagnetic shielding is prepared. The schematic diagram of the preparation process is as follows: figure 1 shown, the steps are as follows:

[0042] (1) Preparation of conductive and thermally conductive sheet layers and insulating and thermally conductive sheet layers

[0043] 1. Mix and knead 100 parts by mass of polyurethane and 5 parts by mass of multi-walled carbon nanotubes to obtain a conductive and thermally conductive mixture. The conductive and thermally conductive mixture is hot-pressed into a sheet shape using a vacuum molding machine. During hot-pressing molding, the temperature of the vacuum molding machine is controlled to be 180° C. and pressure of 10 MPa to obtain a conductive and thermally conductive sheet layer with a thickness of 0.35 mm.

[0044] ② 100 parts by mass of granular polyurethane with a particle size of about 100 μm and 2...

Embodiment 2

[0052] In this embodiment, an insulating and thermally conductive polypropylene composite material with frequency selective electromagnetic shielding is prepared. The schematic diagram of the preparation process is as follows: figure 1 shown, the steps are as follows:

[0053] (1) Preparation of conductive and thermally conductive sheet layers and insulating and thermally conductive sheet layers

[0054] 1. Mix and knead 100 parts by mass of polypropylene and 10 parts by mass of multi-walled carbon nanotubes to obtain a conductive and thermally conductive mixture. The conductive and thermally conductive mixture is hot-pressed into a sheet shape using a vacuum molding machine, and the temperature of the vacuum molding machine is controlled during hot-pressing molding. The temperature was 180° C. and the pressure was 10 MPa to obtain a conductive and thermally conductive sheet layer with a thickness of 0.35 mm.

[0055] ② 100 parts by mass of polypropylene with a particle size ...

Embodiment 3

[0062] In this embodiment, an insulating and thermally conductive polyhexamethylene adipamide composite material with frequency selective electromagnetic shielding is prepared. The schematic diagram of the preparation process is as follows: figure 1 shown, the steps are as follows:

[0063] (1) Preparation of conductive and thermally conductive sheet layers and insulating and thermally conductive sheet layers

[0064] 1. Mix and knead 100 parts by mass of polyhexamethylene adipamide and 50 parts by mass of carbon black to obtain a conductive and thermally conductive mixture. The conductive and thermally conductive mixture is hot-pressed into a sheet shape using a vacuum molding machine, and the vacuum molding machine is controlled during hot-pressing molding. The temperature is 235°C, and the pressure is 10MPa to obtain a conductive and thermally conductive sheet layer with a thickness of 40mm.

[0065] ② 100 parts by mass of polyhexamethylene adipamide powder with a particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com