Automatic and precise positioning lifting and unloading device for machine tools

A precise positioning and automatic technology, applied in metal processing and other directions, can solve the problems of difficult automatic mass production of machine tools, affecting the working efficiency of processing machine tools, and high cost of blanking devices, achieving simple and easy adjustment and control, simple structure and economical. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

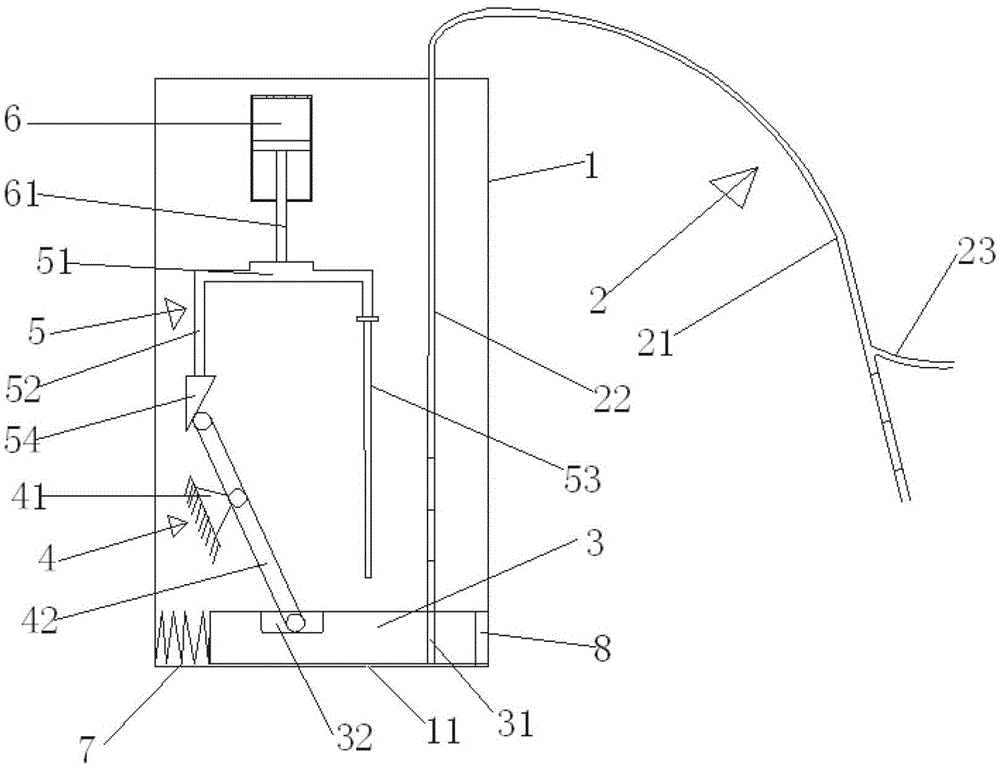

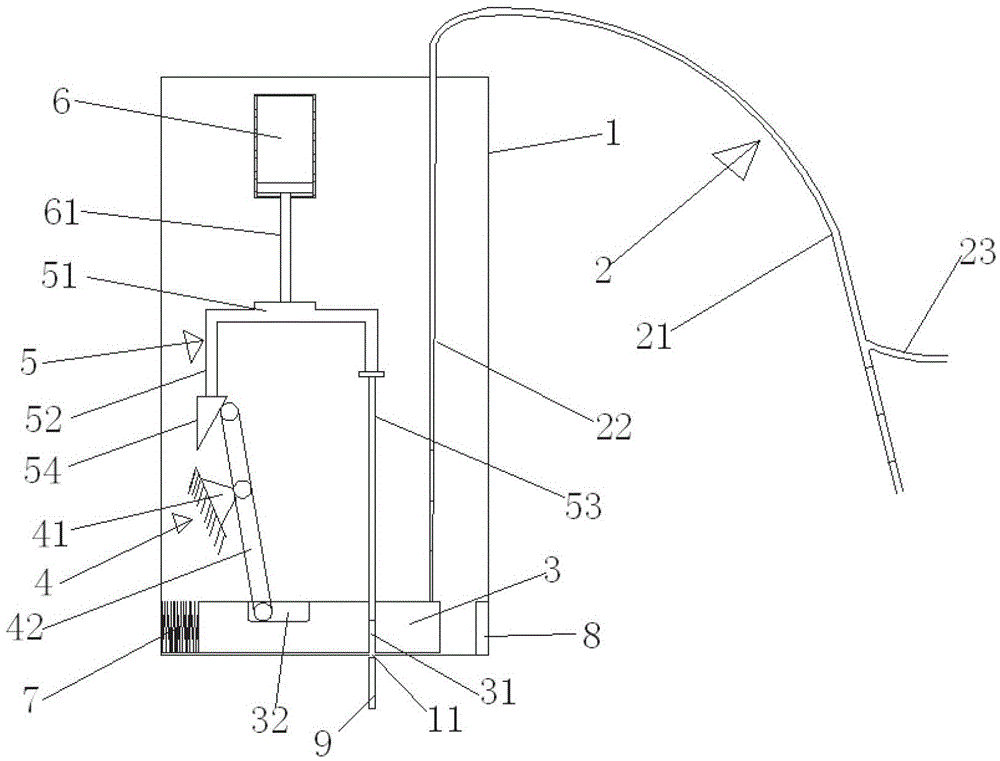

[0024] Such as figure 1 and figure 2 As shown, an automatic and precise positioning lifting and unloading device for a machine tool includes a body 1, a feeding mechanism 2 and a strip slider 3. Based on the direction of use, the slider is horizontally arranged on the bottom of the body, and one end The end face is against one side of the body, and the other end face is positioned and connected to the other side of the body through an elastic device. The end of the slider facing away from the elastic device is vertically provided with a first feed through hole 31, and the first feed through hole 31 is vertically provided on the end of the slider. The upper end of a feeding through hole communicates with the feeding mechanism, and the feeding mechanism can transport the raw material 9 to be processed into the first feeding through hole. A lever mechanism 4, a connecting rod, and Mechanism 5 and cylinder 6 correspond to the connecting rod mechanism, and the bottom of the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com