300mm vertical oxidation furnace heat preservation barrel

A technology of oxidation furnace and heat preservation barrel, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of complex manufacturing process, production line loss, and high cost, and achieves simple manufacturing process, prevention of contamination of silicon wafers, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

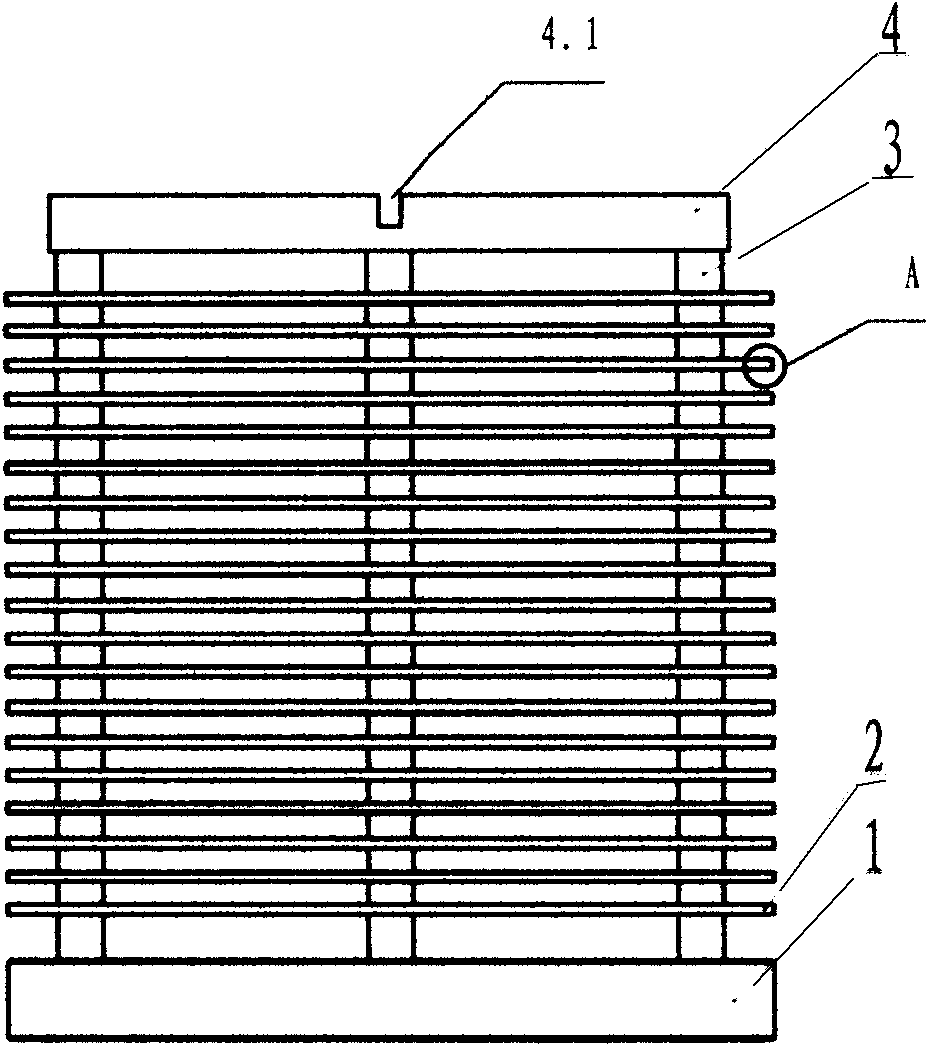

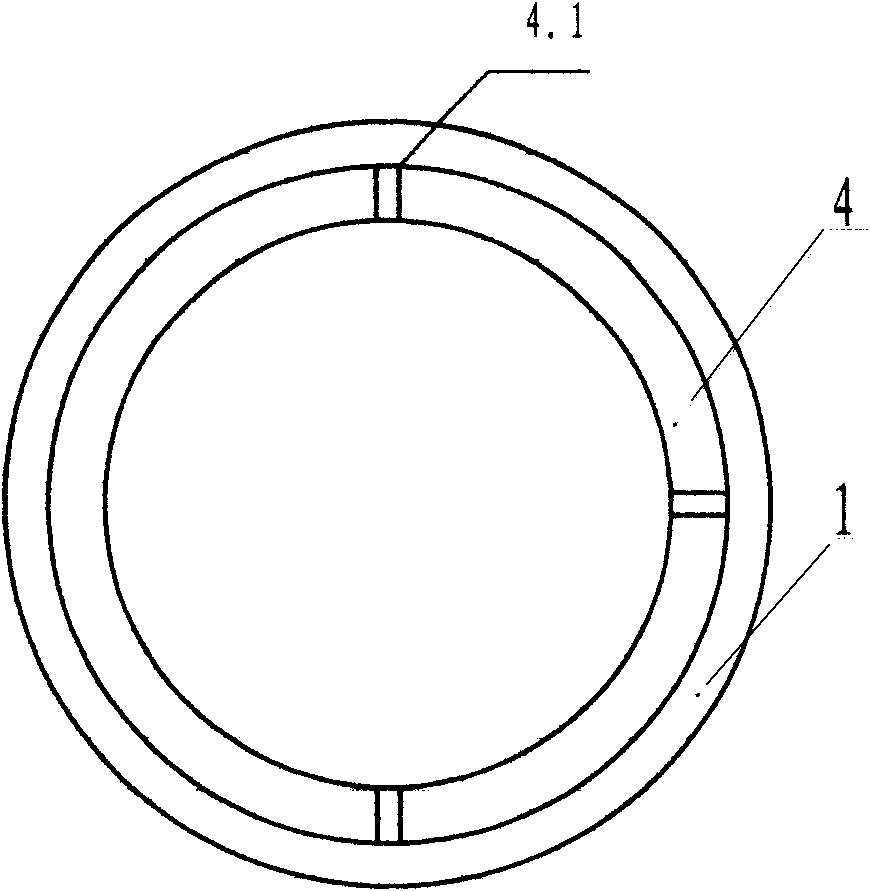

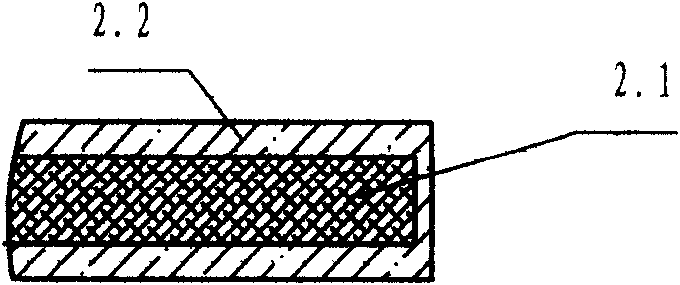

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: embodiment: referring to accompanying drawing, 300mm vertical oxidation furnace insulation barrel is provided with bottom quartz plate 1, middle quartz plate 2, support bar 3 and top quartz plate 4, There are 4 support rods, which are vertically fixedly installed between the bottom quartz plate and the top quartz plate, and there are 19 quartz plates, which are evenly fixed and installed on the support rods at transverse intervals; 3 fixed slots 4.1 for fixing the quartz boat. The bottom quartz plate and the top quartz plate are circular; the middle quartz plate is disc-shaped, and the structure of the middle quartz plate is an OP material layer 2.1 in the middle, and the upper and lower layers and the periphery are coated with high-purity transparent quartz plates Layer 2.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com