Preparation method of polysiloxane modified silicon-containing arylacetylene resin

A polysiloxane and silicon aryl alkyne technology, which is applied in the field of polysiloxane-modified silicon-containing aryl alkyne resin and its preparation field, can solve the problems of insufficiently low viscosity and insufficient mechanical properties of silicon-containing aryl alkyne resin, and achieves the Improved mechanical properties, improved processability, and stable heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

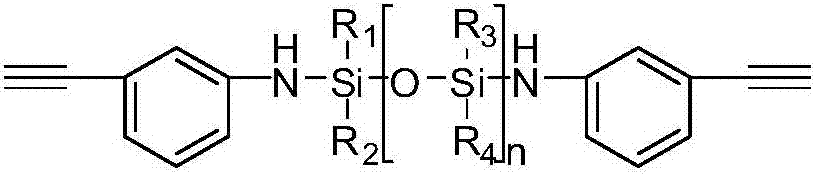

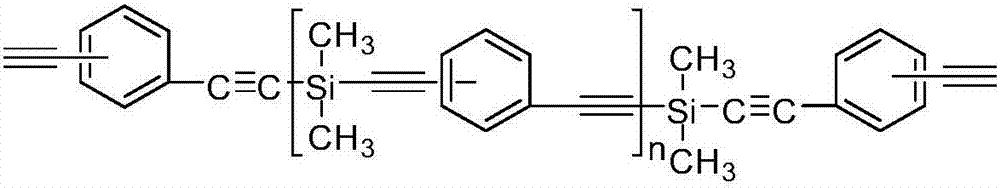

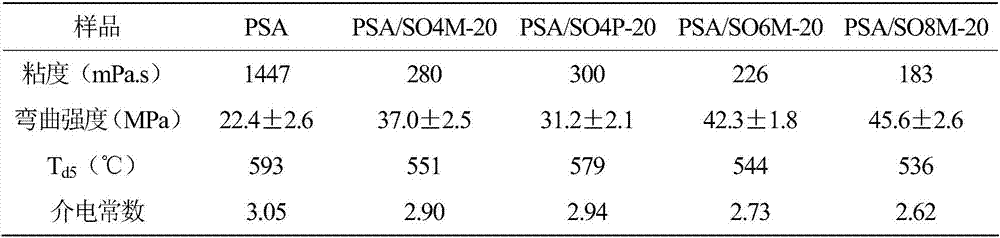

[0043] Example 1. Two (1,3-ethynylanilino) tetramethyldisiloxane modified silicon-containing aryne resin

[0044] 1. Synthesis of bis(1,3-ethynylanilino)tetramethyldisiloxane

[0045] Under nitrogen protection, 30mL of toluene, 14mL of triethylamine (0.1mol) and 11.3mL of m-aminophenylacetylene (0.1mol ); using an ice-salt bath to cool the above mixed solution to -10°C, and drop the mixed solution of 30mL toluene and 10mL 1,3-dichlorotetramethyldisiloxane (0.05mol) into In the above solution, the rate of addition was controlled so that the temperature of the reaction solution was maintained at -10°C; after the dropwise addition was completed, the reaction was continued for 1 hour, then the temperature was raised to 30°C, and the reaction was continued with stirring for 12 hours to obtain a yellow suspension. Remove the precipitate by filtration, wash the filtrate to neutral with deionized water, and dry it with anhydrous sodium sulfate, then filter and distill off the solvent...

Embodiment 2

[0055] Example 2. Two (1,3-ethynylanilino) tetraphenyldisiloxane modified silicon-containing aryne resin

[0056] 1. Synthesis of bis(1,3-ethynylanilino)tetraphenyldisiloxane

[0057] Under nitrogen protection, 30mL of toluene, 14mL of triethylamine (0.1mol) and 11.3mL of m-aminophenylacetylene (0.1mol ); using an ice-salt bath to cool the above mixed solution to -10°C, and drop the mixed solution of 20mL toluene and 18.8mL 1,3-dichlorotetraphenyldisiloxane (0.05mol) through a constant pressure dropping funnel Add to the above solution, during which the rate of addition is controlled so that the temperature of the reaction solution is maintained at -10°C; after the dropwise addition is complete, the reaction is continued for 1 hour, then the temperature is raised to about 80°C, and the reaction is continued for 48 hours with stirring to obtain a yellow suspension. Remove the precipitate by filtration, wash the filtrate to neutral with deionized water, and dry it with anhydrou...

Embodiment 3

[0061] Example 3. Two (1,5-ethynylanilino) hexamethyltrisiloxane modified silicon-containing aryne resin

[0062] 1. Synthesis of bis(1,5-ethynylanilino)hexamethyltrisiloxane

[0063] Under nitrogen protection, 40mL of toluene, 14mL of triethylamine (0.1mol) and 11.3mL of m-aminophenylacetylene (0.1mol ); Use an ice-salt bath to cool the above mixed solution to -10°C, and drop the mixed solution of 20mL toluene and 13.8mL 1,5-dichlorohexamethyltrisiloxane (0.05mol) through a constant pressure dropping funnel Into the above solution, during which the rate of addition is controlled so that the temperature of the reaction solution is maintained at -10°C; after the dropwise addition is complete, the reaction is continued for 1 hour, then the temperature is raised to 60°C, and the reaction is continued for 20 hours with stirring to obtain a yellow suspension. Remove the precipitate by filtration, wash the filtrate to neutral with deionized water, and dry it with anhydrous sodium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com