Stone coal sodium roasting vanadium-extracting method

A technology of sodium roasting and stone coal, applied in the direction of vanadium oxide, process efficiency improvement, etc., can solve the problems of exchange capacity decrease, ion concentration increase, environmental pollution, etc., achieve low consumption, high metal recovery rate, process Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

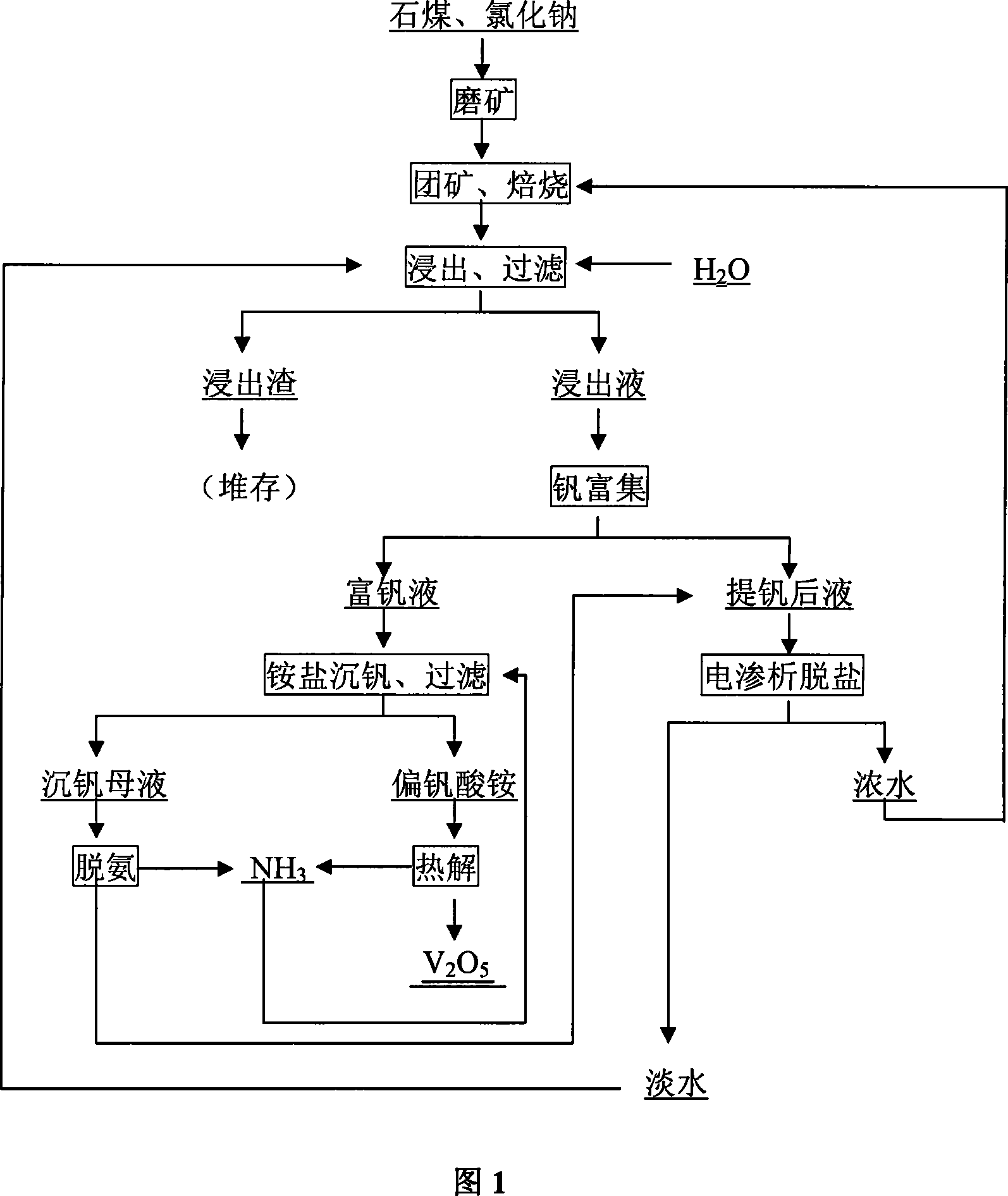

Image

Examples

Embodiment 1

[0021] Add 250g of sodium chloride to 5kg of stone coal ore, mix and grind to -120 mesh agglomerate, roast at 750°C for 2h, add water to leaching the calcined sand at a solid-to-liquid ratio of 1:2 for 1.5h, and use a nanofiltration membrane for the leaching solution (molecular weight cut-off 250) 2.1MPa intercepts vanadium, ammonium chloride is added to the retained solution to precipitate ammonium metavanadate according to 2.5 times the stoichiometric amount, ammonium metavanadate is pyrolyzed at 550°C for 2 hours to obtain the product vanadium pentoxide, and the vanadium precipitated mother liquor is deaminated and returned to the leaching process for nanofiltration The obtained permeate is desalted by electrodialysis, concentrated brine is used for stone coal agglomerates, and fresh water is returned to calcined sand for leaching. The experimental results (g / L) of stone coal sodium roasting, water leaching, nanofiltration concentration, vanadium extraction and electrodialys...

Embodiment 2

[0024] Add 200g of sodium chloride to 5kg of stone coal ore powder (-150 mesh), roast 2h at 800°C with concentrated brine agglomerates in Example 1, and add calcined sand at a solid-to-liquid ratio of 1:2 (fresh water+new water in Example 1 ) leaching for 1.5h, the leaching liquid was intercepted by nanofiltration membrane (molecular mass cut-off: 300) 1.9MPa, and ammonium chloride was added to the retentate liquid at 1.5 times the stoichiometric amount to precipitate ammonium metavanadate, and ammonium metavanadate was pyrolyzed at 530°C for 2 hours to obtain the product Vanadium pentoxide, vanadium precipitation mother liquor is deaminated and permeated liquid is combined into vanadium extraction liquid, vanadium extraction liquid is desalted by electrodialysis, concentrated brine is used for stone coal lump ore, and fresh water is returned to calcined sand for leaching. The experimental results (g / L) of stone coal sodium roasting, water leaching, nanofiltration concentration...

Embodiment 3

[0027] Add 150g of sodium chloride to 5kg of stone coal ore powder (-200 mesh), roast 2h at 760°C with the concentrated water agglomerate in Example 2, and add calcined sand at a solid-to-liquid ratio of 1:2 (fresh water+new water in Example 2 ) leaching for 1.5h, the leach solution is adsorbed vanadium with strong base anion resin (D231), and the negative vanadium resin is desorbed and regenerated with a mixed solution of sodium chloride and sodium hydroxide (NaCl1.2mol, NaOH 1.5mol), and the desorption solution is added by 3.0 times of stoichiometric Ammonium chloride sinks ammonium metavanadate, and ammonium metavanadate is pyrolyzed at 550°C for 2 hours to obtain vanadium pentoxide. After the vanadium precipitation mother liquid is deaminated, it is combined with the post-transaction liquid to form the liquid after vanadium extraction, and the liquid after vanadium extraction is desalted by electrodialysis , Concentrated brine is used for stone coal agglomerates, and fresh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com