Dyeing defect positioning and stripping method for real silk fabric

A silk fabric and color stripping technology, applied in dyeing method, textile and papermaking, bleaching products, etc., can solve the problems of difficult to destroy the structure, damage to silk fibers, and difficult to strip dyes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

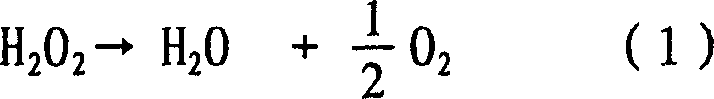

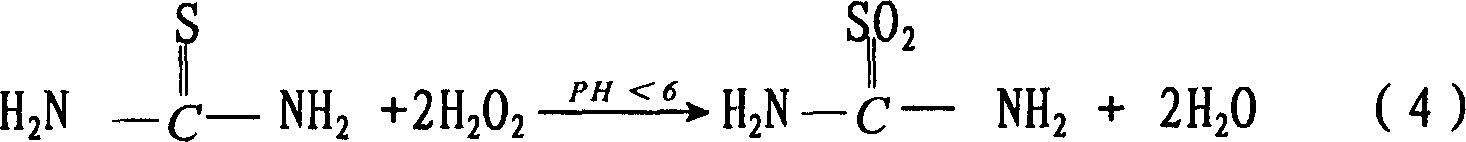

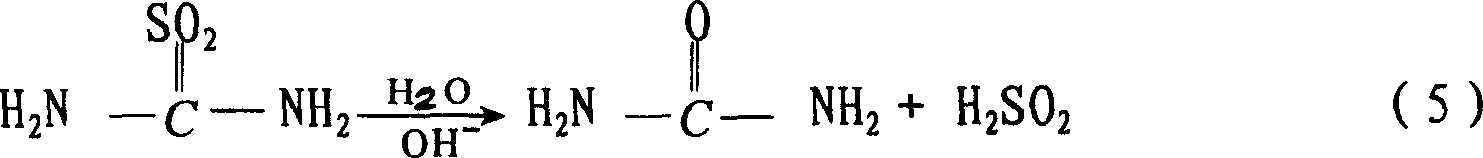

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] For light-colored silk dyed with defective silk, first use pre-media treatment, pre-media treatment agent and process conditions: heptacrystalline water ferrous sulfate 5g / L, 100% hypophosphorous acid 0.5g / L, the rest is water, adjust PH with formic acid To 3-3.5, treat at a temperature of 60°C for 45 minutes. After the pre-medium treatment, rinse at a temperature of 60°C for 15 minutes; on this basis, carry out hydrogen peroxide stripping and bleaching treatment, oxygen bleaching agent and process conditions: 100% concentration of hydrogen peroxide 1.5ml / L, pentacrystalline sodium silicate 5g / L, the rest is water, adjust the pH of the oxygen bleach solution to 8-9, and treat it for 90 minutes at a temperature of 75°C. After oxygen bleaching, adjust the pH of the bleaching solution to 4-5, add 2g / L thiourea, and treat it at 45°C for 45 minutes; finally adjust the pH of the bleaching solution to 8, and perform reduction bleaching after oxygen bleaching at 70°C 45min. ...

Embodiment 2

[0067] For light-colored silk dyed with defective silk, first use pre-media treatment, pre-media treatment agent and process conditions: heptacrystalline water ferrous sulfate 8g / L, 100% hypophosphorous acid 2g / L, the rest is water, use formic acid to adjust the pH to 3-3.5, treat at a temperature of 80°C for 60 minutes. After the pre-media treatment, rinse at a temperature of 80°C for 20 minutes; on this basis, carry out hydrogen peroxide stripping and bleaching treatment, oxygen bleaching agent and process conditions: 100% hydrogen peroxide 3.5ml / L, pentacrystalline sodium silicate 4g / L, the rest is water, adjust the pH of the oxygen bleach solution to 8-9, and treat it for 60 minutes at a temperature of 70°C. After oxygen bleaching, adjust the pH of the bleaching solution to 4-5, add 3g / L thiourea, and treat it at 60°C for 20min; finally adjust the pH of the bleaching solution to 8.5, and restore it after oxygen bleaching at 60°C Bleach for 30min. The peeling whiteness o...

Embodiment 3

[0069] For light-colored silk dyed with defective silk, first use pre-media treatment, pre-media treatment agent and process conditions: 10g / L of ferrous sulfate in heptacrystalline water, 1g / L of 100% hypophosphorous acid, the rest is water, adjust the pH to 3-3.5, treat at a temperature of 70°C for 50 minutes. After the pre-medium treatment, rinse at a temperature of 70°C for 30 minutes; on this basis, carry out hydrogen peroxide stripping and bleaching treatment, oxygen bleaching agent and process conditions: 100% hydrogen peroxide 4ml / L, pentacrystalline sodium silicate 5g / L , the rest is water, the pH of the oxygen bleach solution is adjusted to 8-9, and the temperature is 80°C, and it is treated for 45 minutes. After oxygen bleaching, adjust the pH of the bleach solution to 4-5, add 5g / L thiourea, and treat it at 75°C for 15 minutes; finally adjust the pH of the bleach solution to 9, and perform reduction bleaching after oxygen bleaching at 80°C 15min. The peeling whit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com