High-accuracy-control-molded composite tap hole tubular brick and manufacturing method thereof

A manufacturing method and tapping hole technology, which are applied in the field of metallurgical refractory materials, can solve the problems of uneven performance of the inner and outer walls of the tapping hole brick, the inability to form the tapping hole brick product, and the low precision of the tapping hole brick. Achieve the effect of simple structure, few parts and small amount of processing and trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

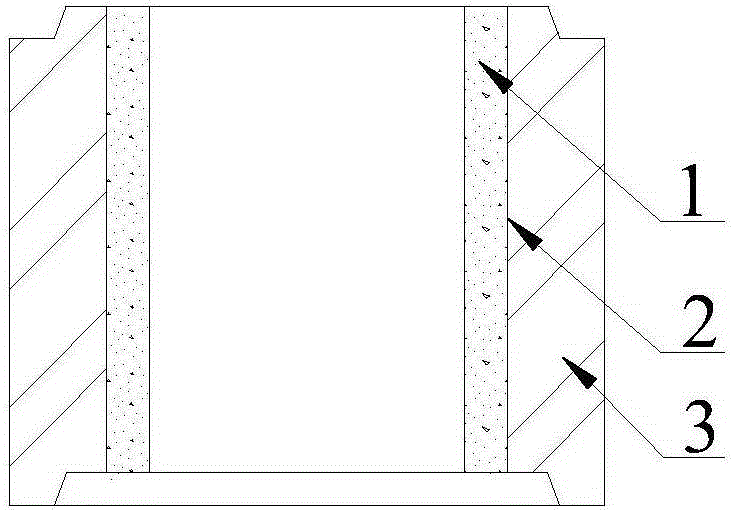

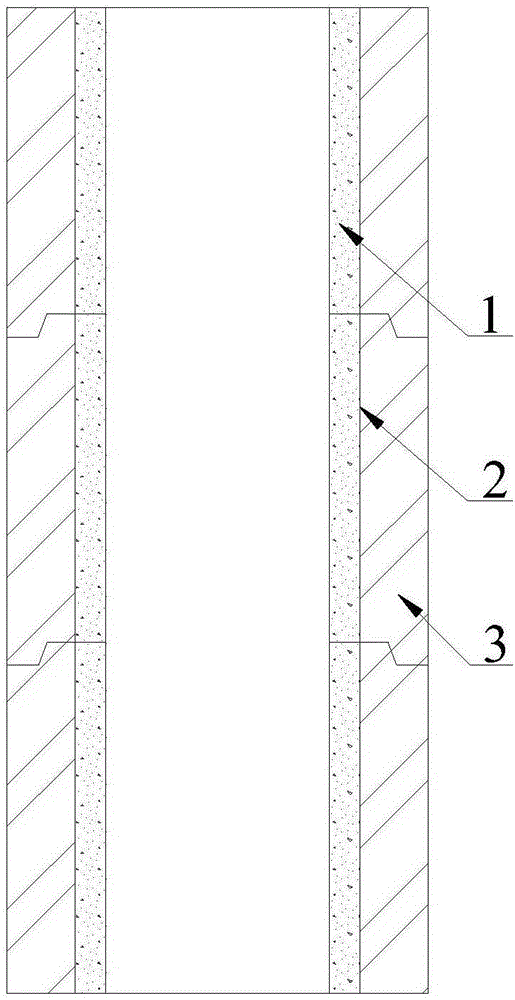

[0033] A high-precision control-molded composite taphole pipe brick is composed of an inner wall 1 and an outer wall 3 in the radial direction, and a thin-walled metal cylinder 2 is arranged between the inner wall and the outer wall;

[0034] Described inner wall 1 raw material weight percent is as follows:

[0035] Main material: high-purity magnesia 81wt%

[0036] Excipients: Graphite 15.3wt%

[0037] Binder: phenolic resin 3.7wt%;

[0038] Described outer wall 3 raw material weight percentages are as follows:

[0039] Main material: Fused magnesia 75wt%

[0040] Excipients: Graphite 12.3wt%

[0041] Antioxidant: metal aluminum powder 9wt%

[0042] Binder: 3.7wt% phenolic resin.

[0043] The purity of the high-purity magnesia is MgO≥97wt%, which is formed by mixing three particle sizes of D≤0.088mm, 0.088mm

Embodiment 2

[0049] A high-precision control-molded composite taphole pipe brick is composed of an inner wall 1 and an outer wall 3 in the radial direction, and a thin-walled metal cylinder 2 is arranged between the inner wall and the outer wall;

[0050] Described inner wall 1 raw material weight percent is as follows:

[0051] Main material: high-purity magnesia 88wt%

[0052] Excipients: Graphite 8.3wt%

[0053] Binder: phenolic resin 3.7wt%;

[0054] Described outer wall 3 raw material weight percentages are as follows:

[0055] Main material: Fused magnesia 78wt%

[0056] Excipients: Graphite 11wt%

[0057] Antioxidant: metal aluminum powder 7.3wt%

[0058] Binder: 3.7wt% phenolic resin.

[0059] The purity of the high-purity magnesia is MgO≥97wt%, and it is formed by mixing three particle sizes of ≤0.088mm, 0.088-1mm, and 1-3mm, and the ratios are 20wt%, 30wt%, and 50wt% respectively; the fused magnesia It is a large crystalline magnesia, the purity of which is MgO≥98.2wt%, Si...

Embodiment 3

[0065] A high-precision control-molded composite taphole pipe brick is composed of an inner wall 1 and an outer wall 3 in the radial direction, and a thin-walled metal cylinder 2 is arranged between the inner wall and the outer wall;

[0066] Described inner wall 1 raw material weight percent is as follows:

[0067] Main material: high-purity magnesia 90wt%

[0068] Excipients: graphite 6.3wt%

[0069] Binder: phenolic resin 3.7wt%;

[0070] Described outer wall 3 raw material weight percentages are as follows:

[0071] Main material: Fused magnesia 85wt%

[0072] Excipients: graphite 6wt%

[0073] Antioxidant: metal aluminum powder 5.3wt%

[0074] Binder: 3.7wt% phenolic resin.

[0075] The purity of the high-purity magnesia is MgO≥97wt%, and it is formed by mixing three particle sizes of ≤0.088mm, 0.088-1mm, and 1-3mm, and the ratios are 20wt%, 30wt%, and 50wt% respectively; the fused magnesia It is a large crystalline magnesia, the purity of which is MgO≥98.2wt%, SiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com