New type 20 roller mill

A rolling mill, a new type of technology, applied in the direction of metal rolling stands, metal rolling mill stands, rolls, etc., can solve the problems of poor actual control effect and weak adjustment force, achieve easy high-precision grinding and processing, improve product quality Dimensional accuracy, stable and reliable equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

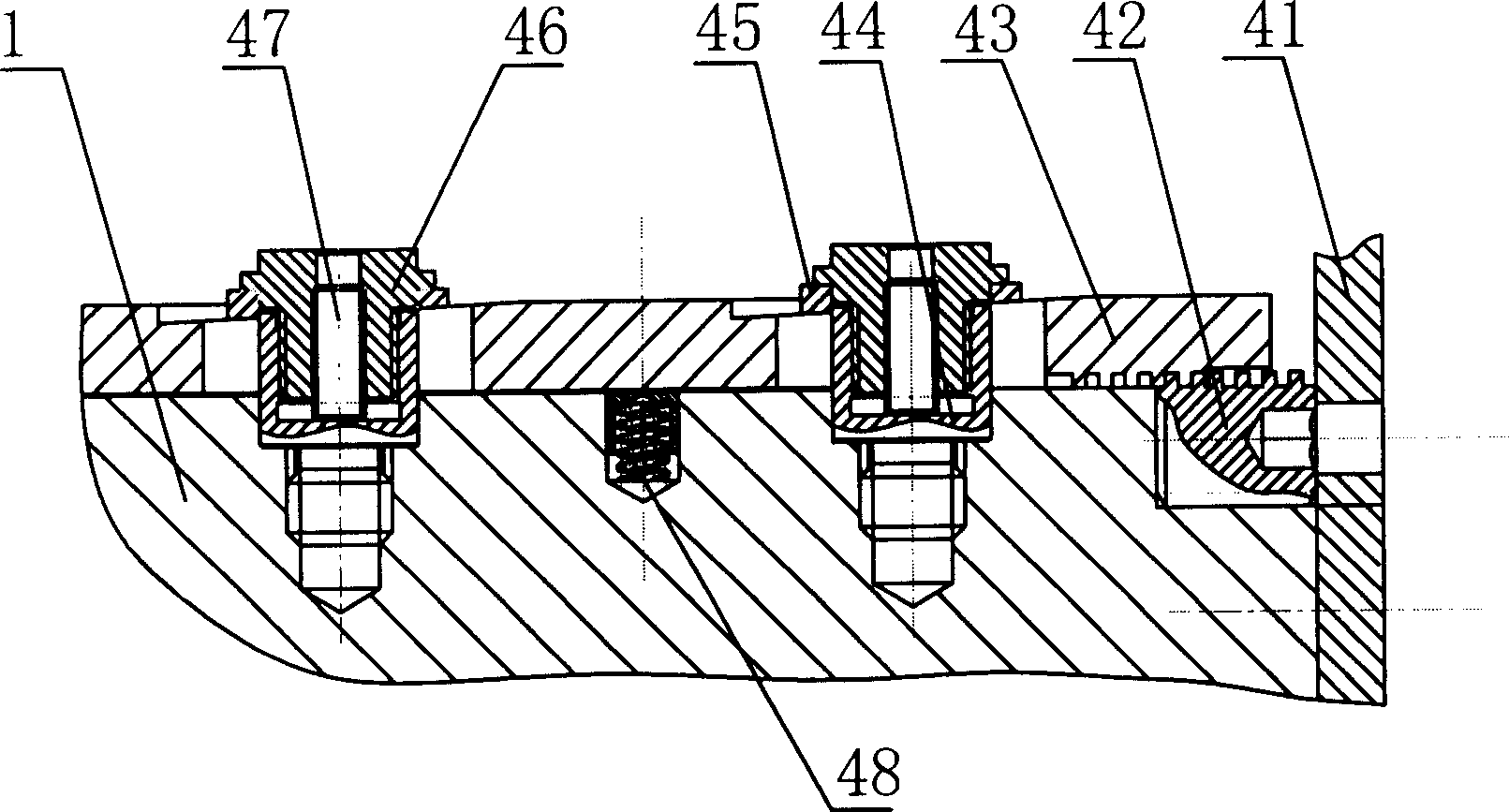

[0046] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

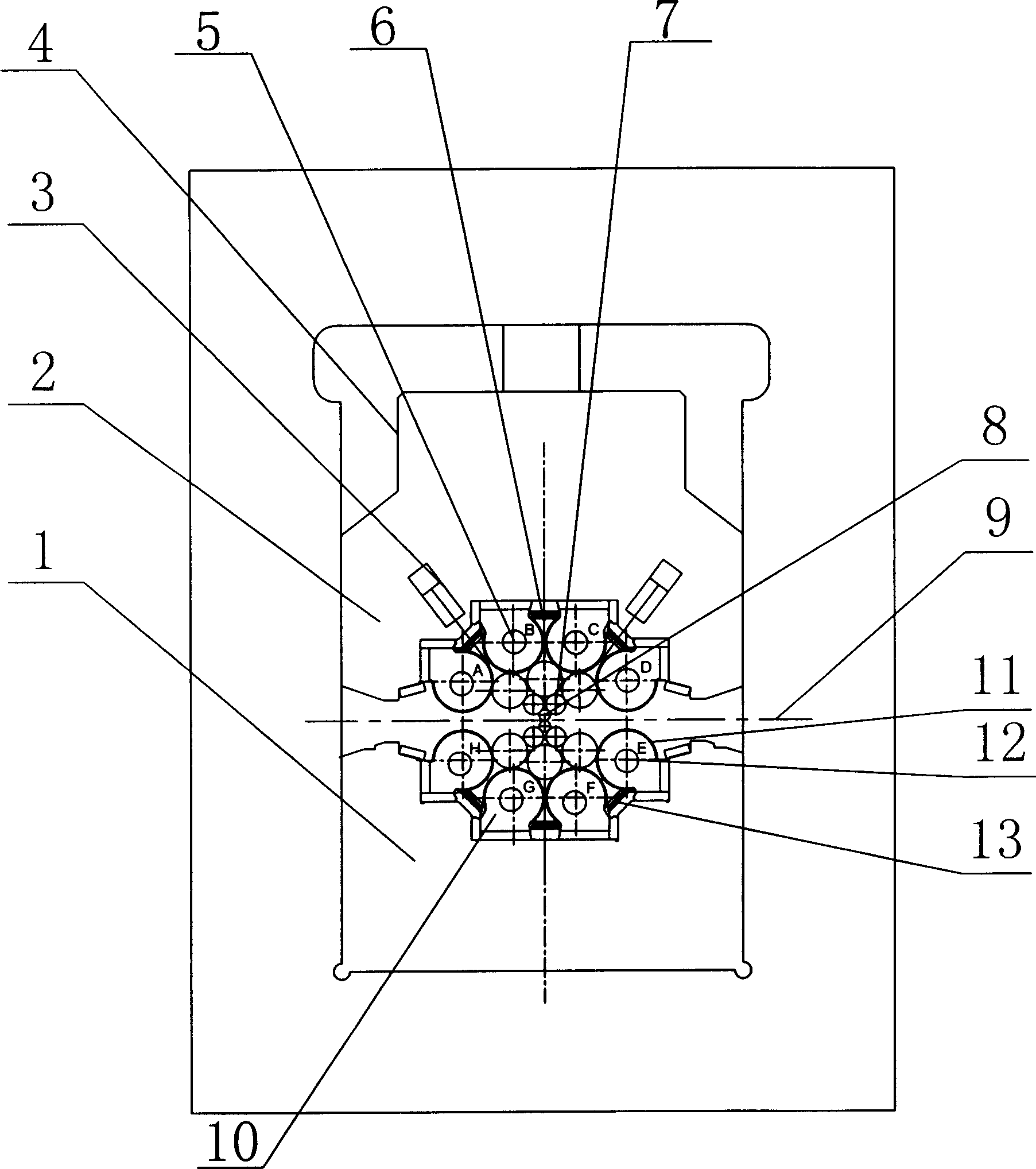

[0047] Such as figure 1 As shown, the novel 20-roll rolling mill of the present invention comprises frame 4, roll system, roll box, pressing device, drive unit, is characterized in that:

[0048] 1) The frame 4 is an overall frame archway with a rectangular shape cast from high-quality steel, and the window of the archway is rectangular. The roller box 2 and the lower roller box 1 symmetrical to the upper roller box 2 are composed, and the sliding mating surfaces of the archway window and the upper and lower roller boxes are planes,

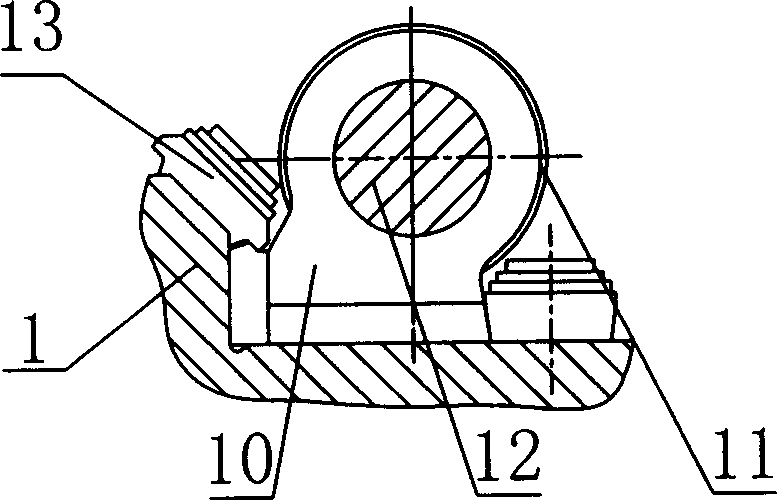

[0049] Such as figure 1 , figure 2 As shown, there are 8 groups of rectangular saddles 10 installed in the roll box of a 20-roll rolling mill, and 4 sets of rectangular saddles are respectively installed in the upper and lower roll boxes, which are symmetrically arranged up and down and left and right. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com