Rotary valve type large torque hydraulic corner self-servo valve

A high-torque, rotary valve technology, applied in the field of servo valves, can solve the problems of insufficient output torque, difficult machining accuracy, and insufficient accuracy, and achieve the effects of simple structure, easy machining accuracy, and easy machining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

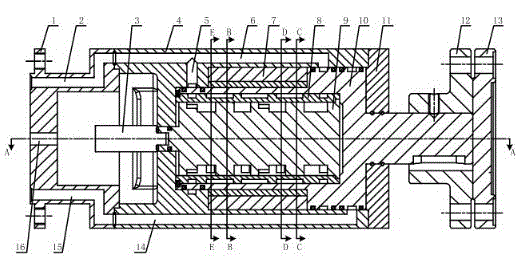

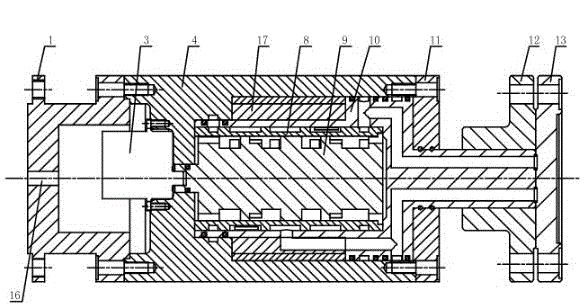

[0056] A rotary valve type high-torque hydraulic rotary angle self-servo valve, such as figure 1 and figure 2 As shown, the rotary valve type high-torque hydraulic rotary self-servo valve includes a connecting cover 1, a motor 3, a cylinder body 4, a valve sleeve 8, a valve core 9, a valve body 10, a fixed stopper 7 and a vane 17.

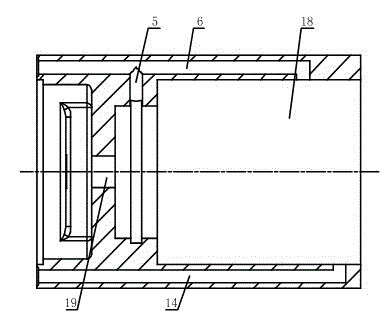

[0057] Such as figure 1 and figure 2 As shown, the connecting cover 1 is concentrically installed on the left end of the cylinder body 4, and the valve body 10 is concentrically installed on such as image 3 In the cylindrical cavity 18 of the shown cylinder body, the right end cover 11 is installed on the right end of the cylinder body 4, the output shaft of the valve body 10 extends out of the right end cover 11, and the flange 12 is installed at the end of the output shaft of the valve body 10, The sealing cover 13 is fixedly installed on the right end of the flange 12 by bolts.

[0058] Such as figure 1 As shown, the upper part and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com