3D glass cover plate, processing method and electronic device

A glass cover plate and processing method technology, applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve problems such as inability to introduce positioning mechanism design, complex processing technology, single shape design, etc., and achieve high yield , simple process, good effect of using experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

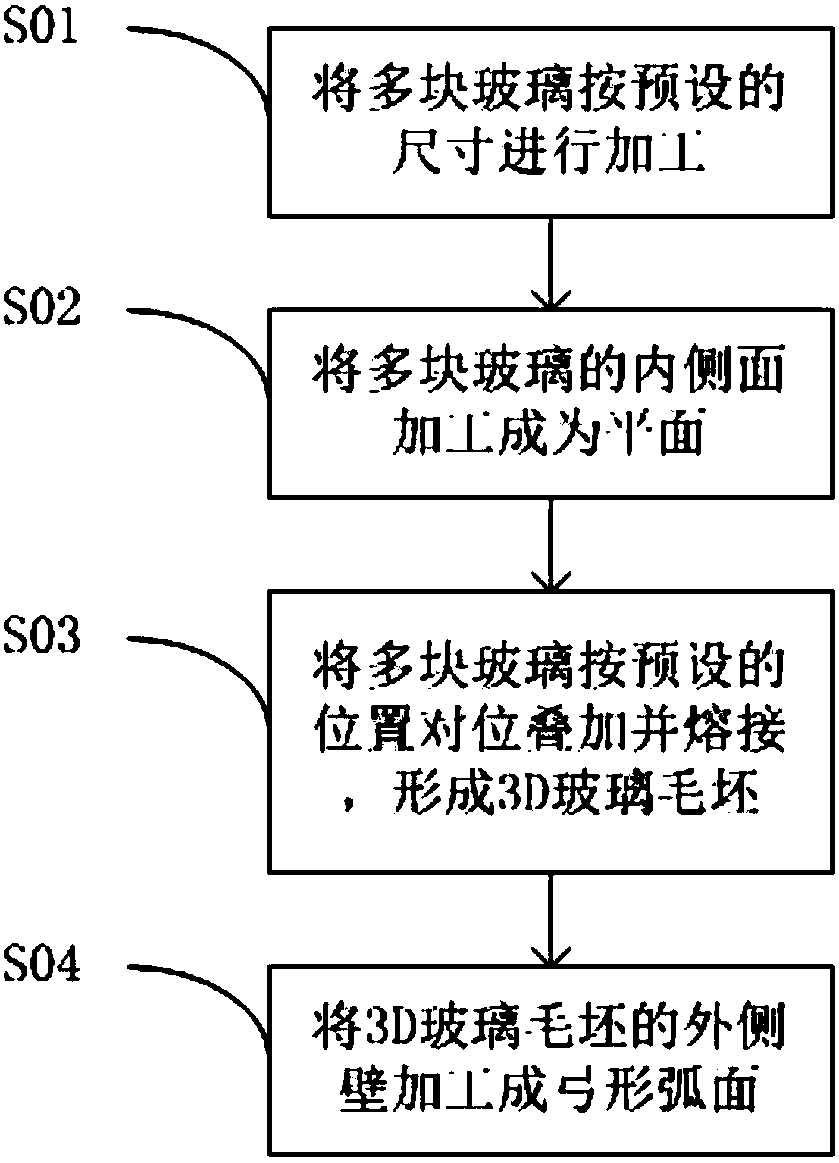

[0026] Such as figure 1 Shown, a kind of 3D glass cover plate processing method comprises the steps:

[0027] Step S01: Processing a plurality of pieces of glass according to a preset size;

[0028] Step S02: Processing the inner surfaces of the multiple pieces of glass into planes;

[0029] Step S03: Align and superimpose multiple pieces of glass according to preset positions and weld them together to form a 3D glass blank;

[0030] Step S04: Processing the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com