Tire baler and production line

A technology of tires and racks, applied in the field of tire packaging equipment, can solve problems affecting production efficiency and require manual operation, and achieve high automation efficiency, improved production safety, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

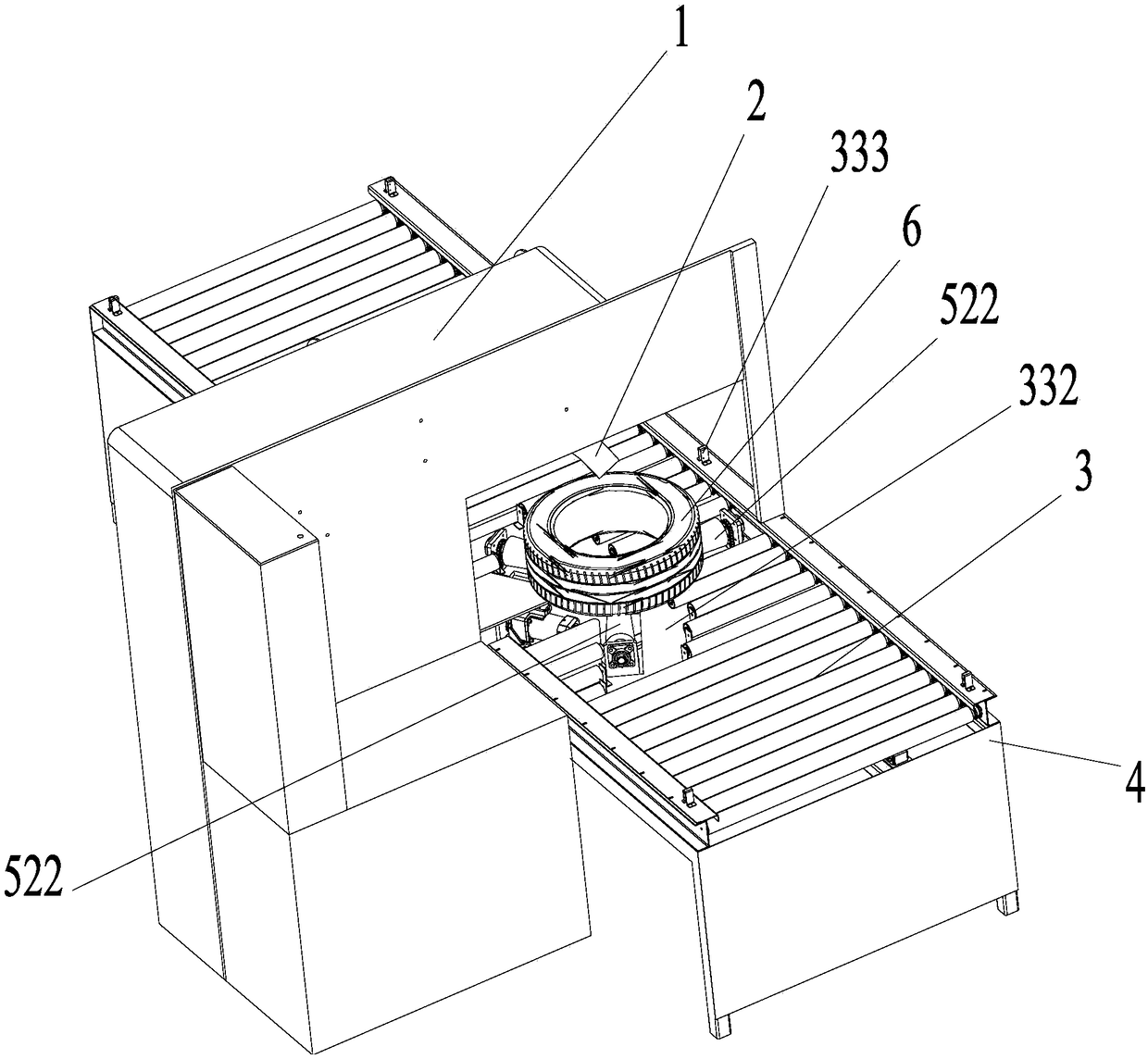

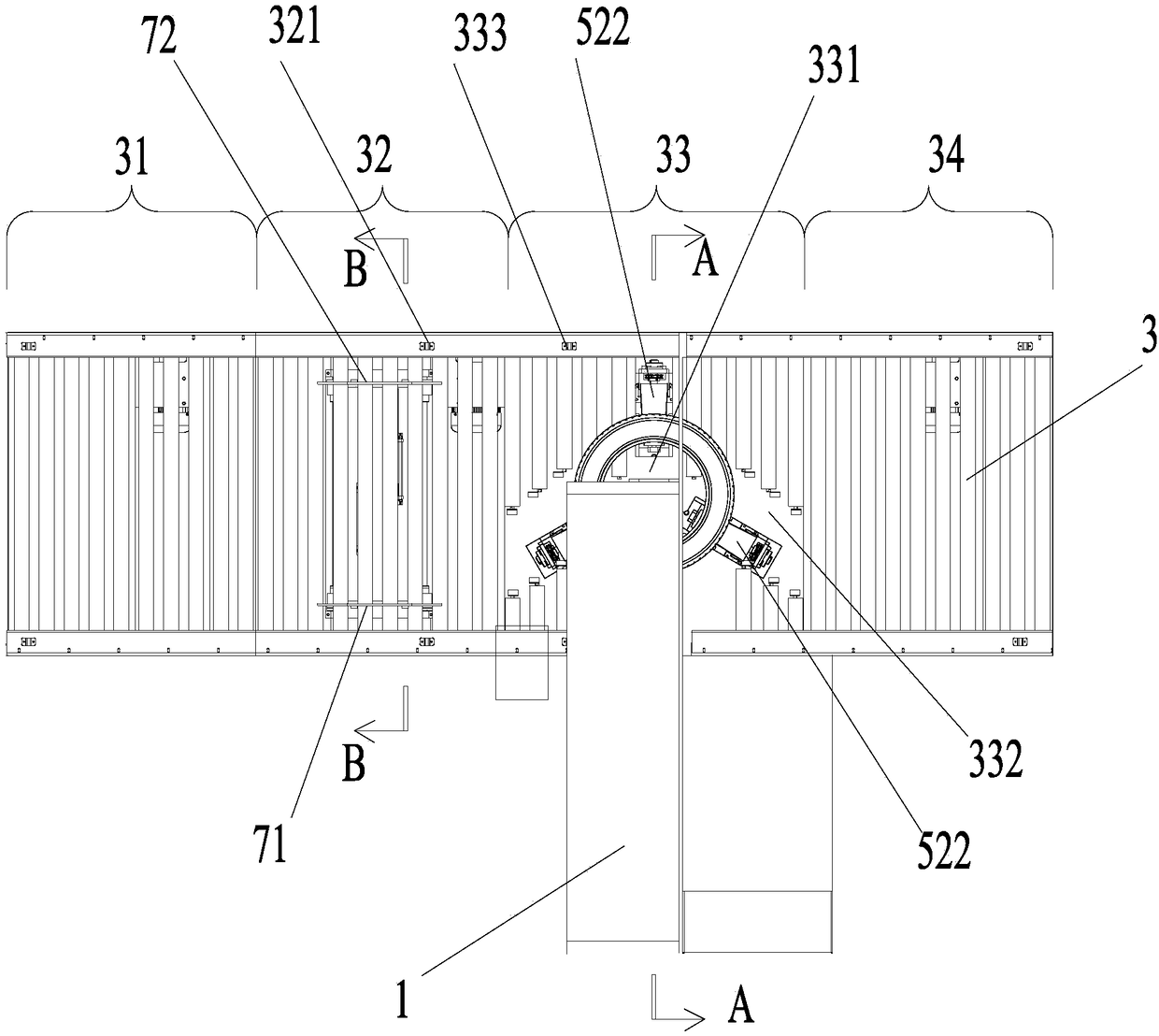

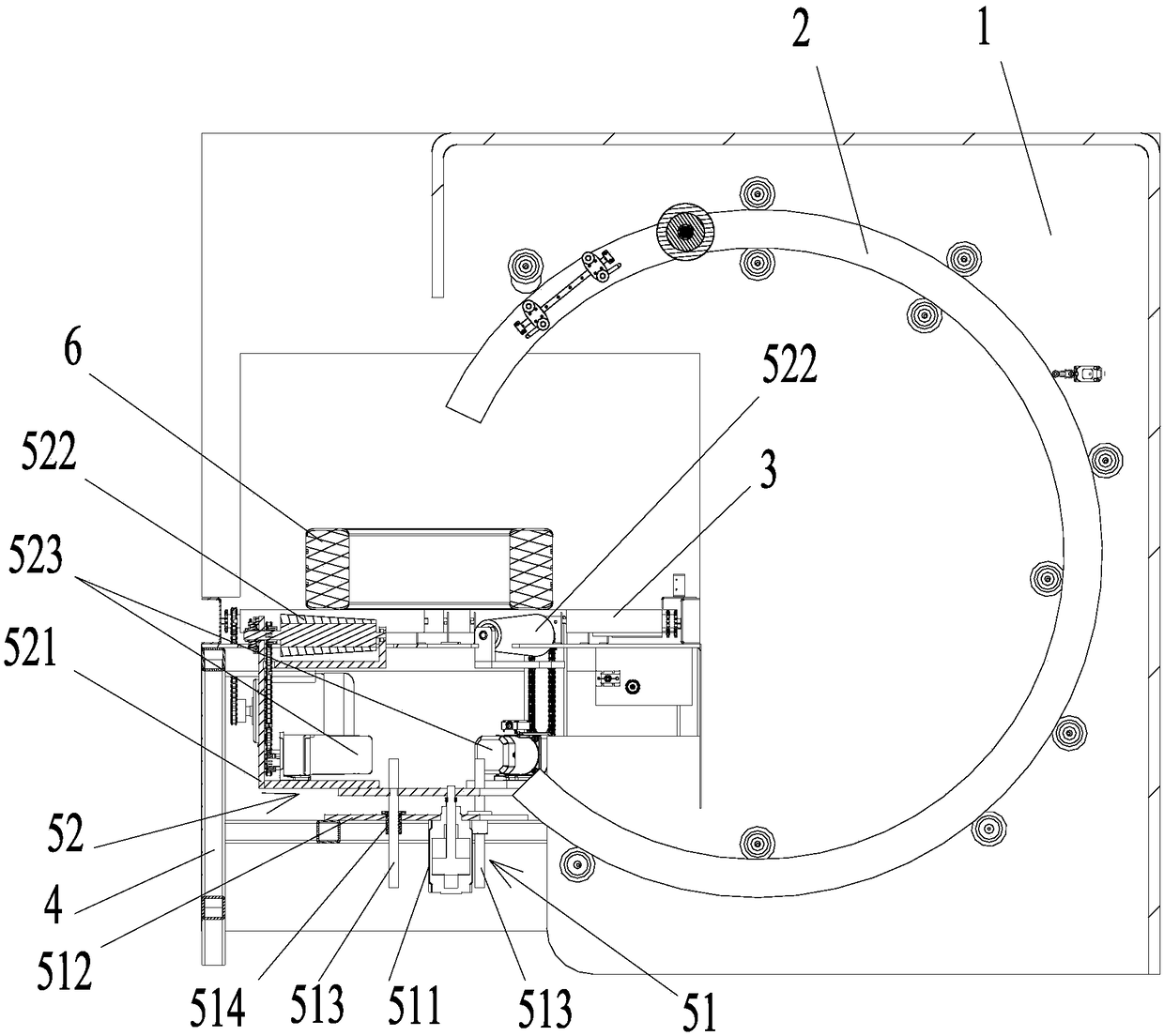

[0065] figure 1 , figure 2 Shown is a tire packing machine 100, including a winding ring frame 1, a C-shaped winding ring 2 and a winding ring drive motor, and the C-shaped winding ring 2 is provided with a packing tape roll support rod, a packing tape guide rod and a tensioner. tightening mechanism; the central controller of the baler controls the winding ring drive motor to drive the C-shaped winding ring 2 to rotate; it also includes a horizontally arranged roller conveyor belt 3, and the roller conveyor belt is arranged on the conveyor belt frame 4 on.

[0066] When the C-shaped winding ring 2 is in a static state, its gap is located on the side, and the roller conveyor belt 3 passes through the gap position of the C-shaped winding ring 2 .

[0067] The roller conveyor belt 3 is provided with a feeding area 31 , a clamping and positioning area 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com