Diamond wire slicing cooling liquid integrated treatment method for sapphire and silicon wafers

A treatment method and coolant technology, applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc., can solve the problems of polluting the cutting environment, affecting bearing operation, and low cutting yield, so as to improve the quality of processing, The effect of reducing product manufacturing cost and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

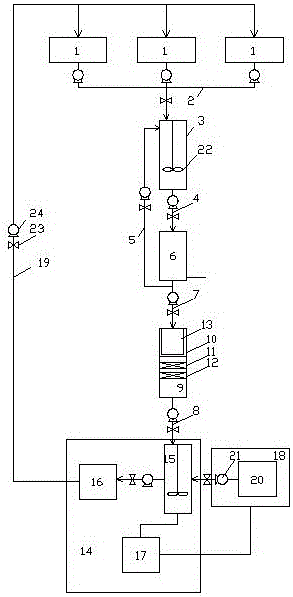

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] An integrated processing method for sapphire and silicon chips using diamond wire slice coolant, the processing method is as follows:

[0027] According to the capacity of the slicer to match the equipment quantity and storage weight, several slicers are connected to the storage tank through the first pipeline, the storage tank is connected to the plate and frame filter press through the second pipeline and the muddy water bypass pipeline, and the plate The frame filter press is connected to the precision filter tank through the third pipeline, and the precision filter tank is connected to the product liquid management system through the fourth pipeline. The precision filter tank is equipped with a precision filter cartridge, an adsorption resin layer and an activated carbon adsorption layer. , the precision filter cartridge is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com