Small-sized bearing drop height type continuous ultrasonic cleaning method and device

An ultrasonic cleaning and drop technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of inability to meet the requirements of automatic cleaning of precision bearings, high operation intensity, low efficiency, etc. Use performance and market competitiveness, improve continuous conveying, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

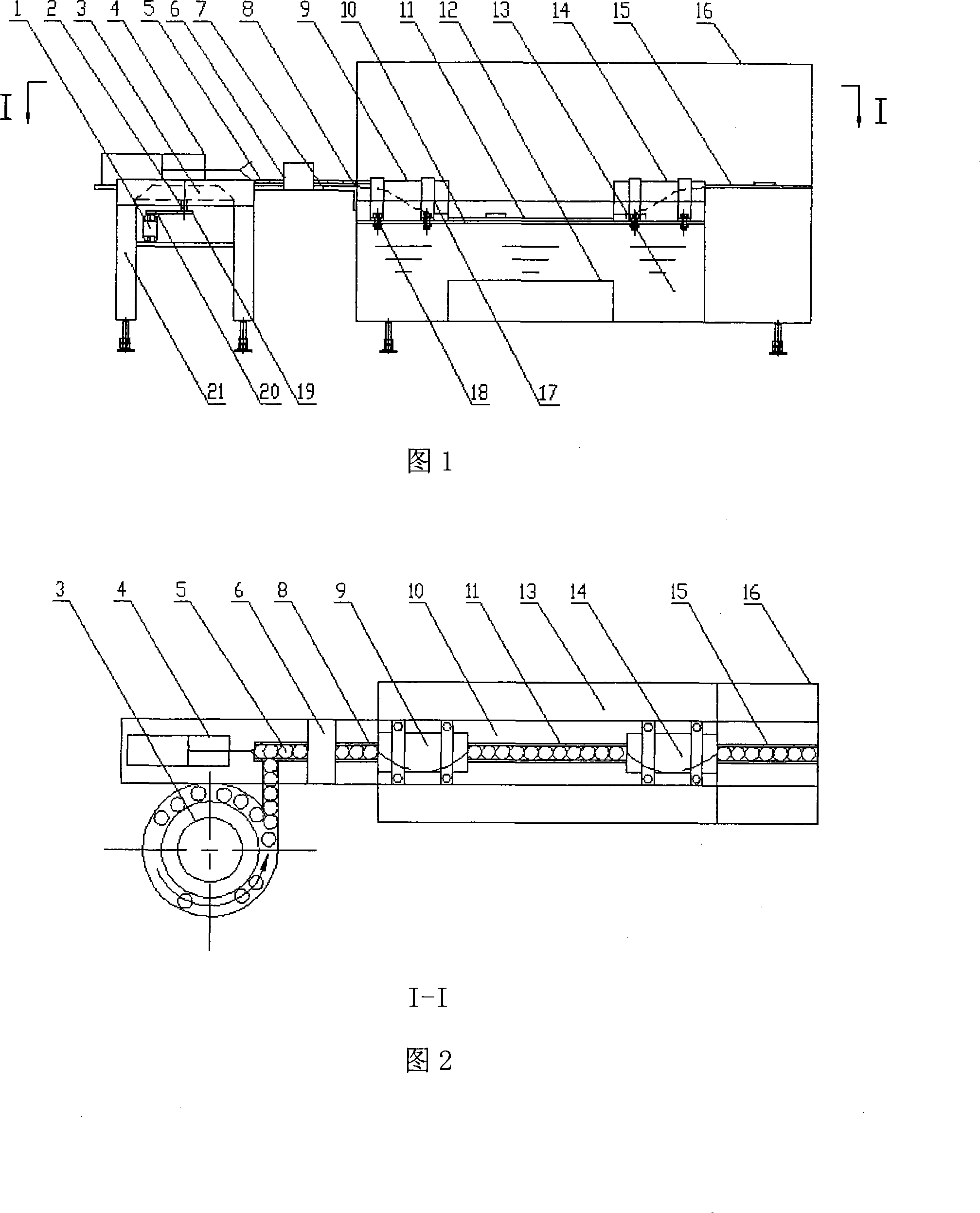

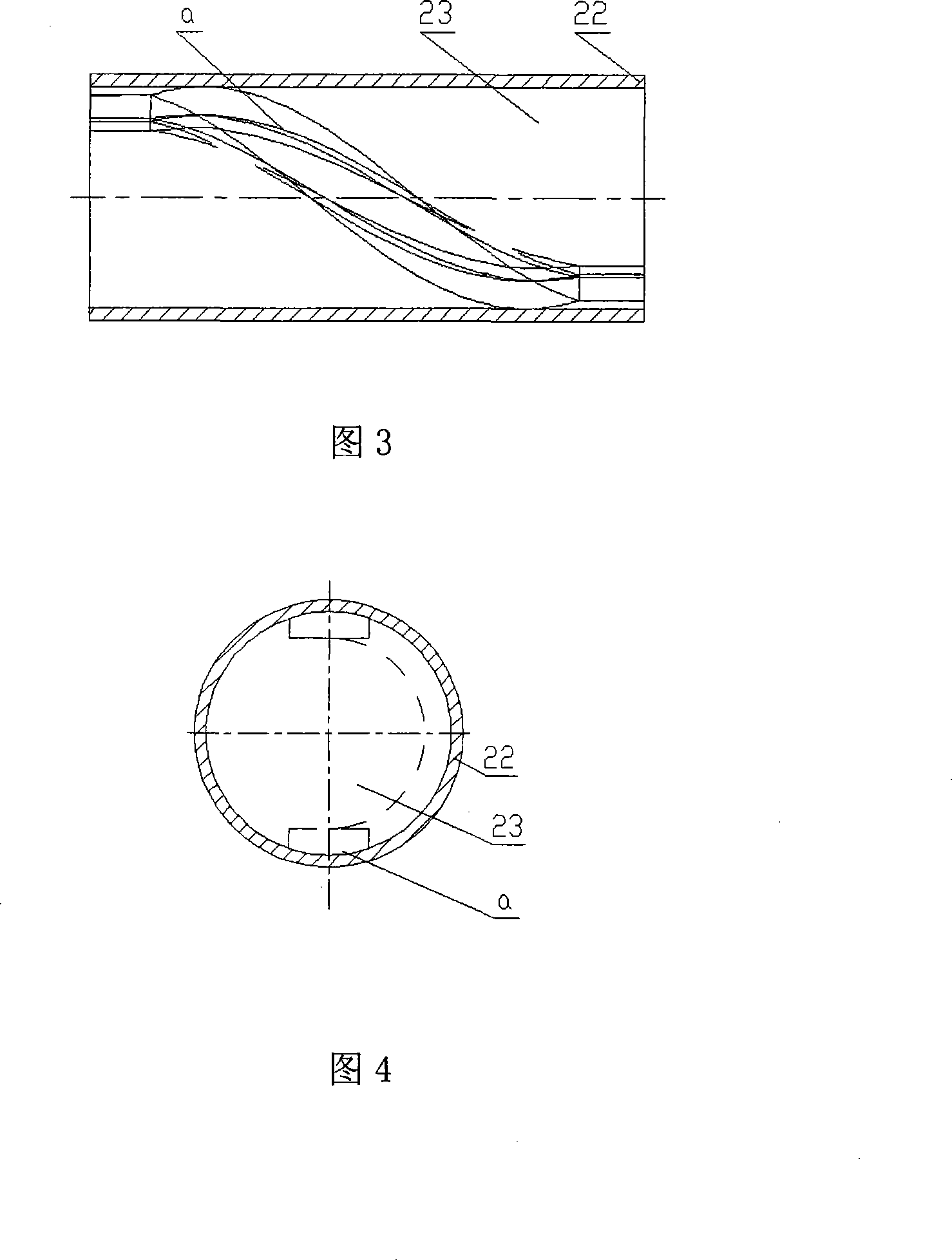

[0012] The concrete embodiment of the present invention will be described in detail in conjunction with the accompanying drawings, and the structure of the drop device and the entire ultrasonic cleaning process will be described. The equipment consists of two parts: feeding and cleaning. The outer diameter of the cleaned bearing 5 ranges from 5 to 90 mm. The size of the spiral grooves of the left dropper 9 and the right dropper 14, the ratio of length to diameter, and the ratio of cylinder diameter to groove width are determined according to the bearing size; Groove width is determined according to bearing 5 external diameters, and groove width is slightly larger than bearing 5 external diameters, and groove depth is slightly less than bearing 5 wide. Taking the cleaning of bearings with an outer diameter of 22mm as an example, the structure and size of the left dropper 9 and the right dropper 14 are determined as follows: the diameter of the cylinders of the left flipper 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com