Automatically detecting machine for antirust coating in pipeline

An internal anti-corrosion and detection machine technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem of inability to detect the thickness of the inner coating of the pipeline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

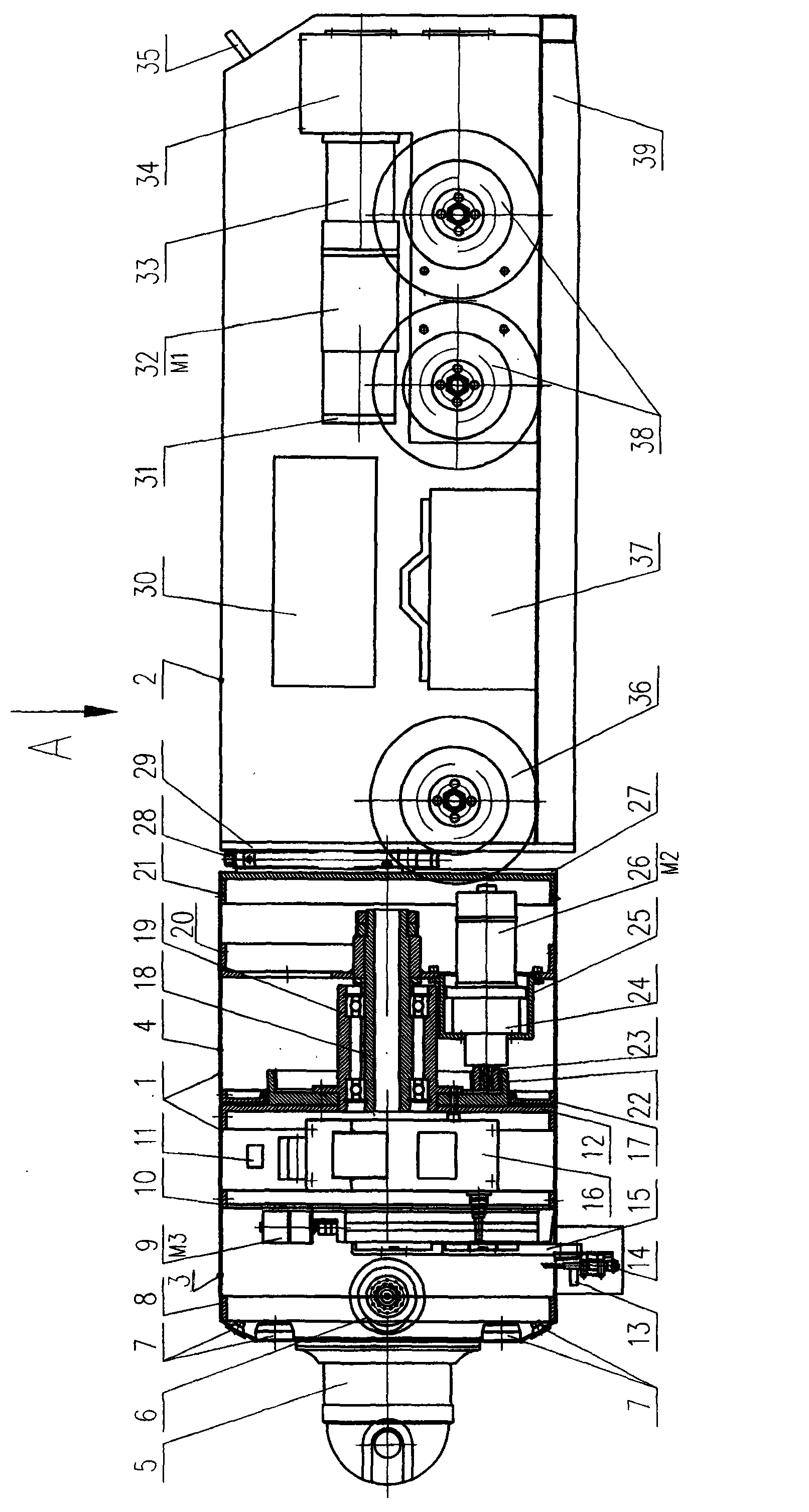

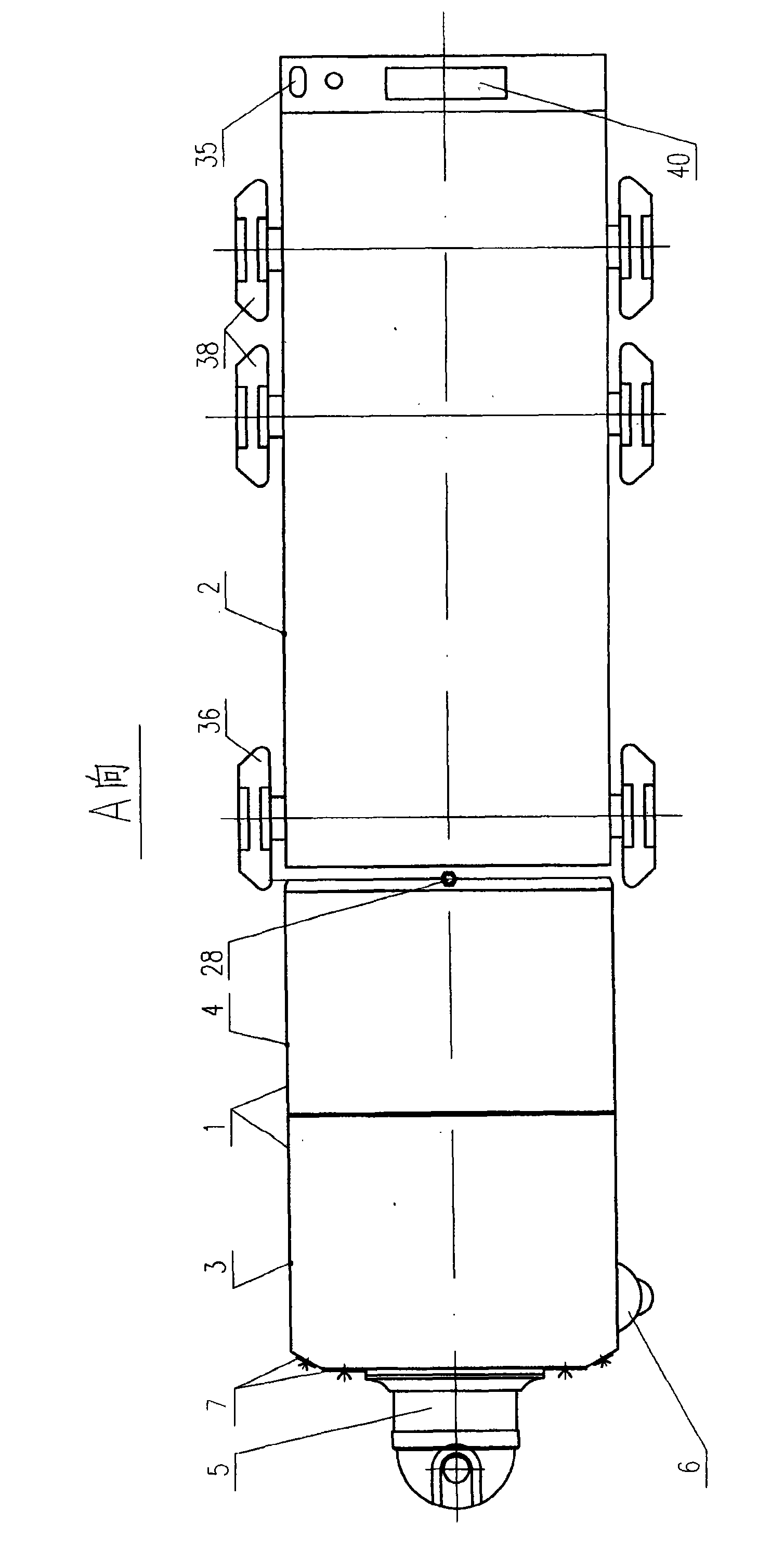

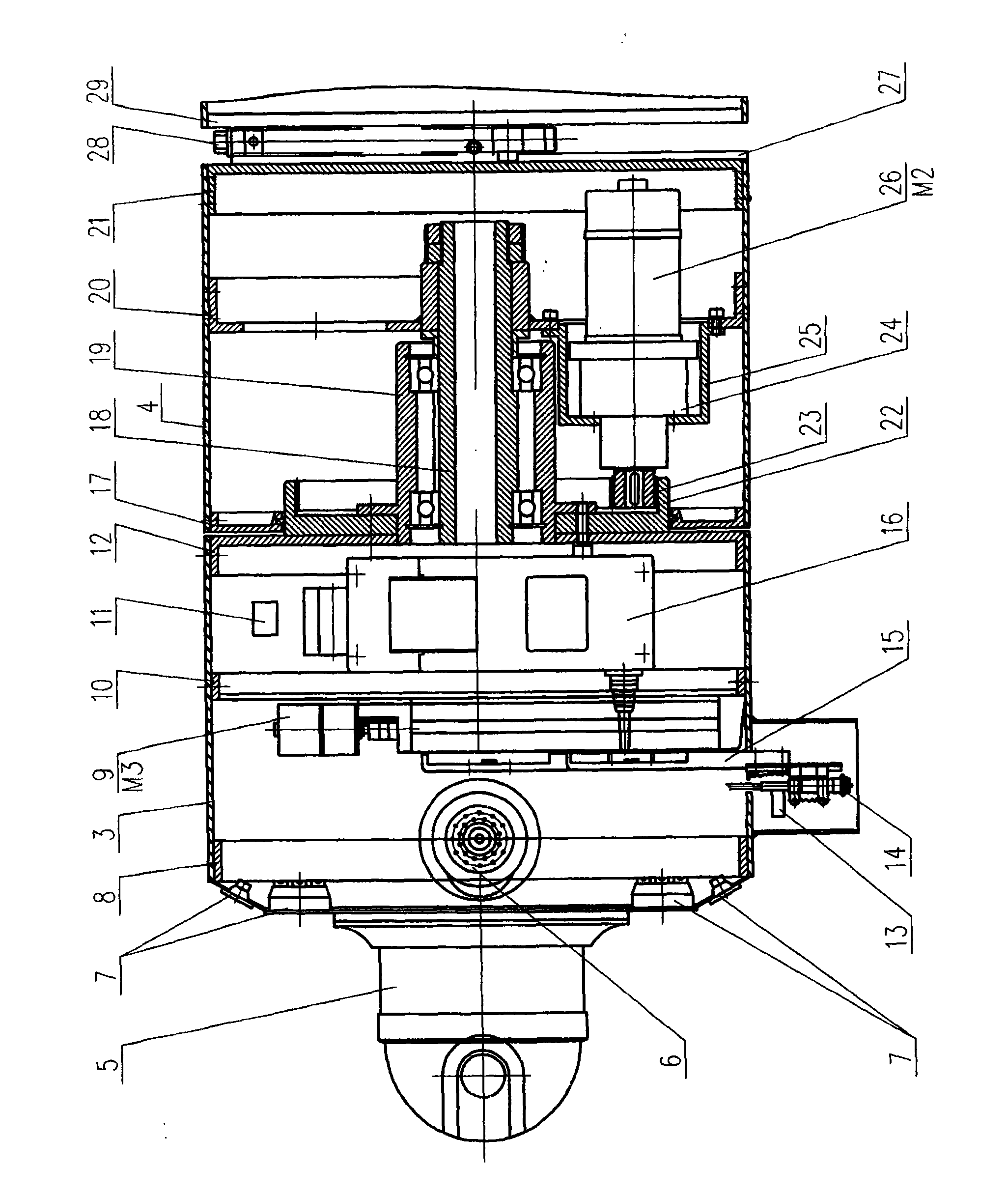

[0018] An embodiment is illustrated in conjunction with the accompanying drawings:

[0019] attached figure 1 , 2 , 3, 1 is the detection head, 2 is the driving body, 3 is the rotating shell, 4 is the fixed shell, 5 is the front camera, 6 is the side camera, 7 is the LED lighting, 8 is the front ring, 9 is the telescopic Motor (M3), 10 is the middle bracket ring, 11 is the inner camera, 12 is the rear rotation ring, 13 is the limit switch, 14 is the thickness measuring probe, 15 is the telescopic rod, 16 is the thickness gauge, 17 is the closed ring, 18 is a hollow shaft, 19 is a shaft sleeve, 20 is a middle support ring, 21 is a rear end cover, 22 is an inner gear ring, 23 is a small gear, 24 is a harmonic reducer, 25 is a bracket, and 26 is a head rotating motor (M2), 27 is a sliding guide (skateboard), 28 is an adjusting screw, 29 is a front cover of the drive body, 30 is an airborne remote control box, 31 is a travel motor brake, 32 is a travel motor (M1), and 33 is a R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com