Retarder-free waterproof magnesium ammonium phosphate cement and preparation method thereof

A magnesium ammonium phosphate cement and water resistance technology, which is applied in the field of civil engineering materials, can solve the problems of reducing the strength of MPC materials and the improvement effect of the water resistance of MPC materials is limited, and achieves the effects of reducing porosity, prolonging setting time and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

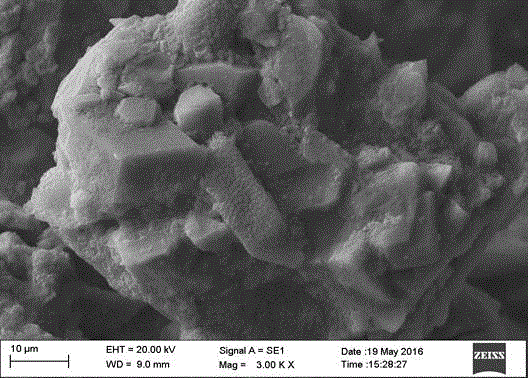

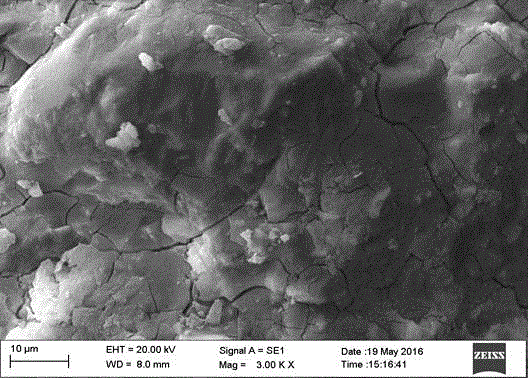

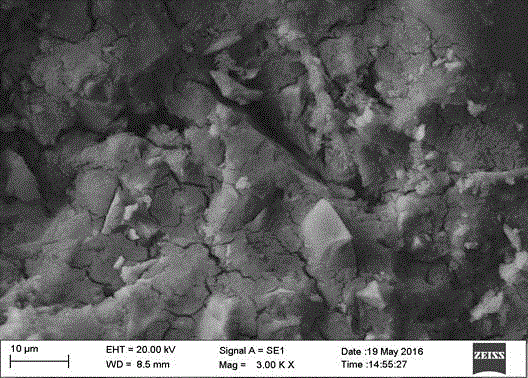

[0032]1. Preparation of graphene oxide-coated dead-burned magnesia: Dissolve graphene oxide powder in absolute ethanol, and use an ultrasonic cleaner to sonicate for 40-60 minutes to obtain a uniformly dispersed graphene oxide solution. Put the graphene oxide solution into a three-necked flask, and under the condition of continuous stirring (300r / min), add the deadened magnesium oxide powder in 5 to 8 times, and add all the deadened magnesium oxide powder and graphene oxide within 30 minutes. The mass ratio is 100:60 in turn. After the addition, keep the water bath at a constant temperature of 65°C for 12 hours. During the reaction, add absolute ethanol to the three-necked flask continuously so that the content of absolute ethanol meets the mass ratio of graphene oxide to 100:1. After the reaction, the reaction solution is dried in a freeze dryer to obtain graphene oxide-coated dead-burned magnesium oxide.

[0033] 2. Preparation of magnesium ammonium phosphate cement: take g...

Embodiment 2

[0035] 1. Preparation of graphene oxide-coated dead-burned magnesia: Dissolve graphene oxide powder in absolute ethanol, and use an ultrasonic cleaner to sonicate for 40-60 minutes to obtain a uniformly dispersed graphene oxide solution. Put the graphene oxide solution into a three-necked flask, and under the condition of continuous stirring (300r / min), add the deadened magnesium oxide powder in 5 to 8 times, and add all the deadened magnesium oxide powder and graphene oxide within 30 minutes. The mass ratio is 100:80 in turn. After the addition, keep the water bath at a constant temperature of 65°C for 12 hours. During the reaction, add absolute ethanol to the three-necked flask continuously so that the content of absolute ethanol meets the mass ratio of graphene oxide to 100:1. After the reaction, the reaction solution is dried in a freeze dryer to obtain graphene oxide-coated dead-burned magnesium oxide.

[0036] 2. Preparation of magnesium ammonium phosphate cement: take ...

Embodiment 3

[0038] 1. Preparation of graphene oxide-coated dead-burned magnesia: Dissolve graphene oxide powder in absolute ethanol, and use an ultrasonic cleaner to sonicate for 40-60 minutes to obtain a uniformly dispersed graphene oxide solution. Put the graphene oxide solution into a three-necked flask, and under the condition of continuous stirring (300r / min), add the deadened magnesium oxide powder in 5 to 8 times, and add all the deadened magnesium oxide powder and graphene oxide within 30 minutes. The mass ratio is 100:50 in turn. After the addition, keep the water bath at a constant temperature of 65°C for 12 hours. During the reaction, add absolute ethanol to the three-necked flask continuously so that the content of absolute ethanol meets the mass ratio of graphene oxide to 100:1. After the reaction, the reaction solution is dried in a freeze dryer to obtain graphene oxide-coated dead-burned magnesium oxide.

[0039] 2. Preparation of magnesium ammonium phosphate cement: take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com