Processing method for inhibiting recrystallization of aluminum alloy sheet

A technology of an aluminum alloy sheet and a processing method is applied in the processing field of inhibiting the recrystallization of the aluminum alloy sheet, so as to achieve the effects of avoiding and reducing the occurrence of recrystallization, obvious economic and social benefits, and improving strength and fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

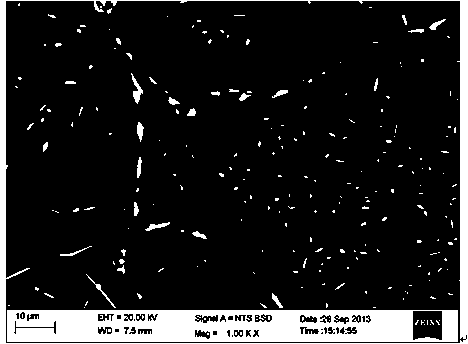

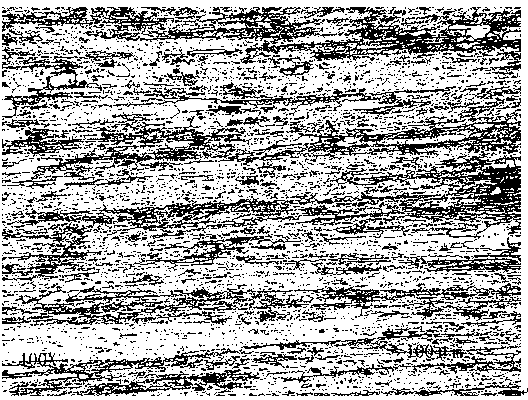

Image

Examples

Embodiment 1

[0043] Embodiment 1: The raw material of aluminum alloy consists of 0.06 parts of Si, 0.13 parts of Fe, 2.20 parts of Cu, 2.30 parts of Mg, 6.30 parts of Zn, 0.11 parts of Zr, 0.05 parts of Ti and the balance in parts by weight Al, a total of 100 parts. and achieved by the following steps:

[0044] Step 1: The mixed raw materials were melted at 730°C for 10 hours, and then semi-continuous casting was carried out at a temperature of 700°C and a casting speed of 45mm / min. The cross-sectional size of the slab was 420×1600mm.

[0045] Step 2: Homogenize the slab at 460°C for 36 hours. After homogenization, quickly transfer the slab to a special cooling room for strong wind cooling and spray cooling, and cool the slab to 105°C within 30 minutes Next, after the slab has cooled to room temperature, it is sawed and face milled.

[0046] Step 3: Preheat the slab to 400°C within 4 hours, keep it warm for 30 minutes, then roll the slab to a plate with a set thickness of 20mm, and cut t...

Embodiment 2

[0051] Embodiment 2: The aluminum alloy raw material is made up of 0.06 parts of Si, 0.13 parts of Fe, 2.20 parts of Cu, 2.30 parts of Mg, 6.30 parts of Zn, 0.11 parts of Zr, 0.05 parts of Ti and the balance in parts by weight Al, a total of 100 parts. and achieved by the following steps:

[0052] Step 1: The mixed raw materials were melted at 750°C for 8 hours, and then semi-continuous casting was carried out at a temperature of 680°C and a casting speed of 40mm / min. The cross-sectional size of the slab was 420×1600mm.

[0053] Step 2: Homogenize the slab at 470°C for 36 hours. After homogenization, quickly transfer the slab to a special cooling room for spray cooling. Cool the slab to below 105°C within 40 minutes. After the slab has cooled to room temperature it is sawn and face milled.

[0054] Step 3: Preheat the slab to 400°C within 3 hours, keep it warm for 40 minutes, then roll the slab to a plate with a set thickness of 20mm, and cut the head and tail.

[0055] Ste...

Embodiment 3

[0058] Embodiment 3: The aluminum alloy raw material is made up of 0.06 parts of Si, 0.13 parts of Fe, 2.20 parts of Cu, 2.30 parts of Mg, 6.30 parts of Zn, 0.11 parts of Zr, 0.05 parts of Ti and the balance in parts by weight Al, a total of 100 parts. and achieved by the following steps:

[0059] Step 1: Melt the mixed raw materials at 730°C for 12 hours, then perform semi-continuous casting at a temperature of 680°C and a casting speed of 50mm / min. The cross-sectional size of the slab is 420×1600mm.

[0060] Step 2: Homogenize the slab at 470°C for 36 hours. After homogenization, quickly transfer the slab to the cooling room for air cooling to 390°C, then spray cooling, and cool the slab to within 50 minutes Below 105°C, after the slab is cooled to room temperature, it is sawed and face milled.

[0061] Step 3: Preheat the slab to 420°C within 5 hours, keep it warm for 10 minutes, then roll the slab to a plate with a set thickness of 20mm, and cut the head and tail.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com