High-strength high-toughness medium and large-diameter non-quenched-and-tempered steel for direct cutting and production process thereof

A high-strength toughness, non-quenched and tempered steel technology, applied in the direction of manufacturing tools, metal processing equipment, workpiece surface treatment equipment, etc., can solve the problems of environmental pollution, steel oxidation, increased energy consumption, etc., to promote diffusion and prevent austenite Effect of grain growth and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

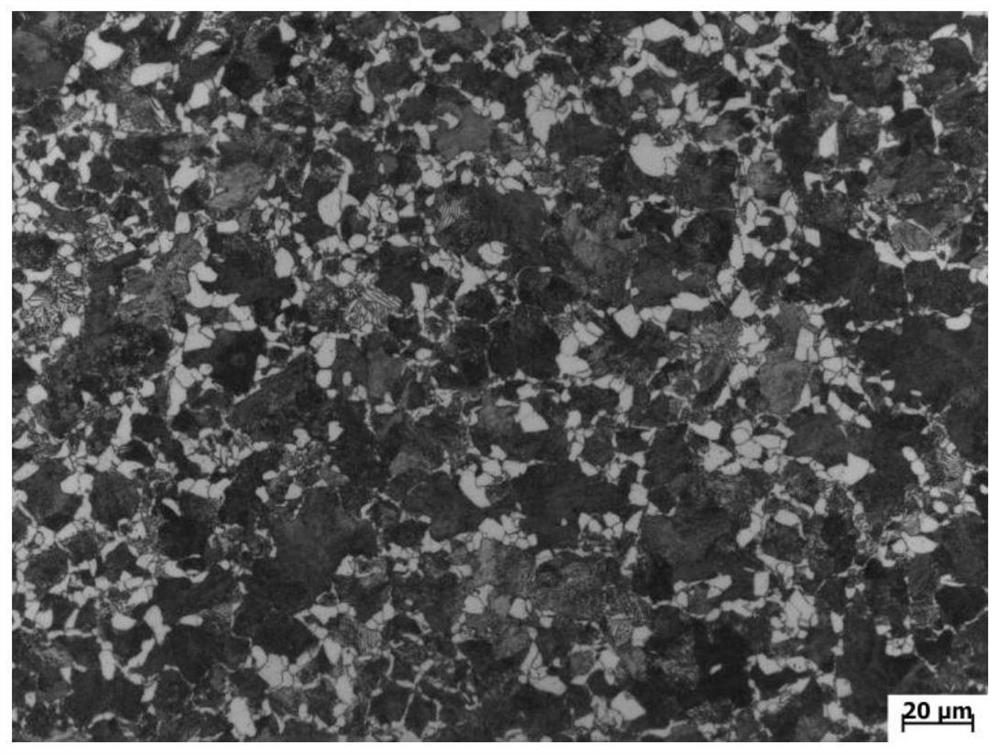

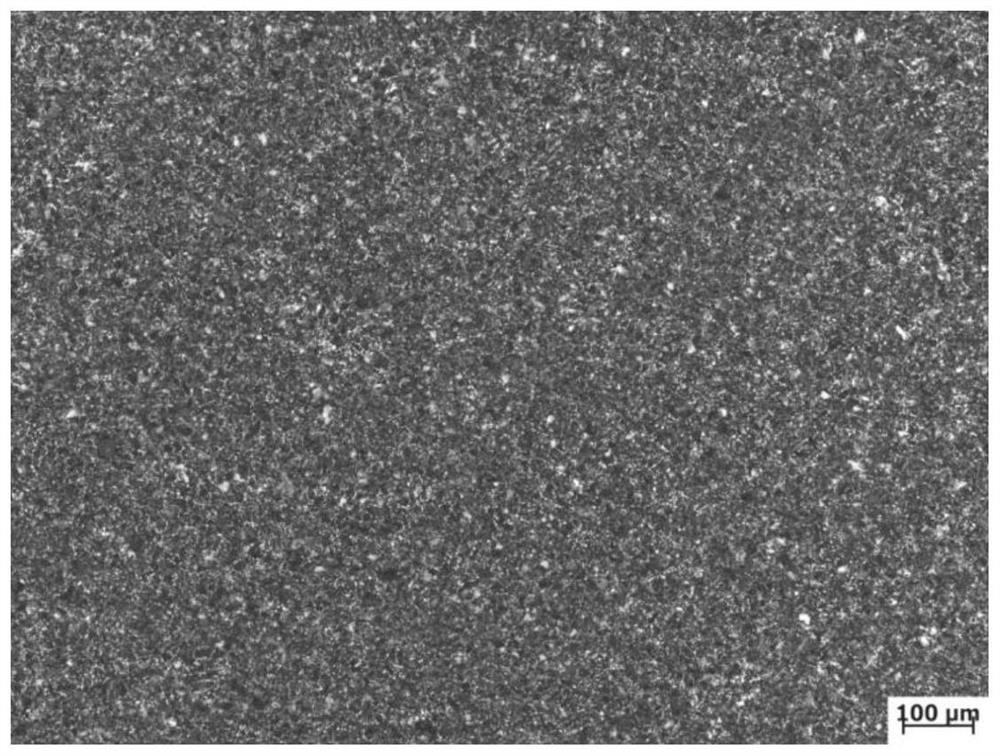

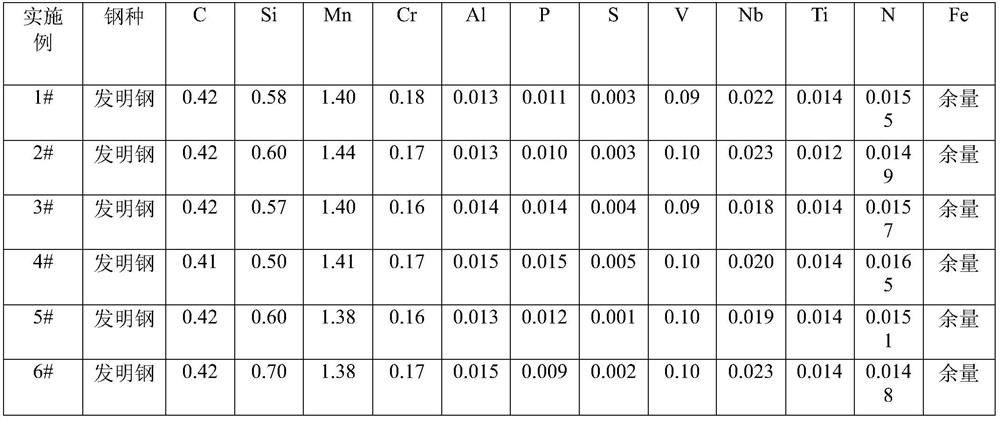

[0036]The diameter of the round steel involved in this embodiment is 140mm, and its chemical composition is calculated by mass percentage: C: 0.42%, Si: 0.58%, Mn: 1.40%, P: 0.011%, S: 0.003%, Cr: 0.18%, V: 0.09%, Nb: 0.022%, Ti: 0.014%, Ni: 0.014%, Mo: 0.011%, Al: 0.013%, Cu: 0.017%, N: 155ppm, H: 1.0ppm, O: 17ppm; balance It is Fe and unavoidable impurities.

[0037] (1) Mix the materials according to the ingredients, after smelting, after smelting, the molten steel is cast into a P500 continuous casting round billet with a superheat of 18-35 °C for the whole process, and the continuous casting billet is ≥500 °C and enters the pit for slow cooling for ≥36 hours; The cast round billet enters the walking beam heating furnace for heating, and is heated in three stages of preheating section, heating section and soaking section. °C, the heating time in the soaking section is 3h; finally the heated billet is obtained;

[0038] (2) After the steel billet is descaled by high-press...

Embodiment 2

[0045] The diameter of the round steel involved in this embodiment is 110mm, and its chemical composition is calculated by mass percentage: C: 0.42%, Si: 0.60%, Mn: 1.44%, P: 0.010%, S: 0.003%, Cr: 0.17%, V: 0.10%, Nb: 0.023%, Ti: 0.012%, Ni: 0.016%, Mo: 0.003%, Al: 0.013%, Cu: 0.020%, N: 149ppm, H: 1.0ppm, O: 20ppm; balance It is Fe and unavoidable impurities.

[0046] (1) Mix the materials according to the ingredients, after smelting, after smelting, the molten steel is cast into a P500 continuous casting round billet with a superheat of 18-35 °C for the whole process, and the continuous casting billet is ≥500 °C and enters the pit for slow cooling for ≥36 hours; The cast round billet enters the walking beam heating furnace for heating, and is heated in three stages of preheating section, heating section and soaking section. At 1240°C, the heating time in the soaking section is 3h; finally the heated billet is obtained;

[0047] (2) After the steel billet is descaled by hi...

Embodiment 3

[0054] The diameter of the round steel involved in this embodiment is 80mm, and its chemical composition is calculated by mass percentage: C: 0.42%, Si: 0.57%, Mn: 1.40%, P: 0.014%, S: 0.004%, Cr: 0.16%, V: 0.09%, Nb: 0.018%, Ti: 0.014%, Ni: 0.013%, Mo: 0.010%, Al: 0.014%, Cu: 0.015%, N: 157ppm, H: 0.8ppm, O: 17ppm; balance It is Fe and unavoidable impurities.

[0055] (1) Mix the materials according to the ingredients, after smelting, after smelting, the molten steel is cast into a P500 continuous casting round billet with a superheat of 18-35 °C for the whole process, and the continuous casting billet is ≥500 °C and enters the pit for slow cooling for ≥36 hours; The cast round billet enters the walking beam heating furnace for heating, and is heated in three stages: preheating section, heating section, and soaking section. 1240°C, the heating time in the soaking section is 2h; finally the heated billet is obtained;

[0056] (2) After the steel billet is descaled by high-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com